Table of Contents

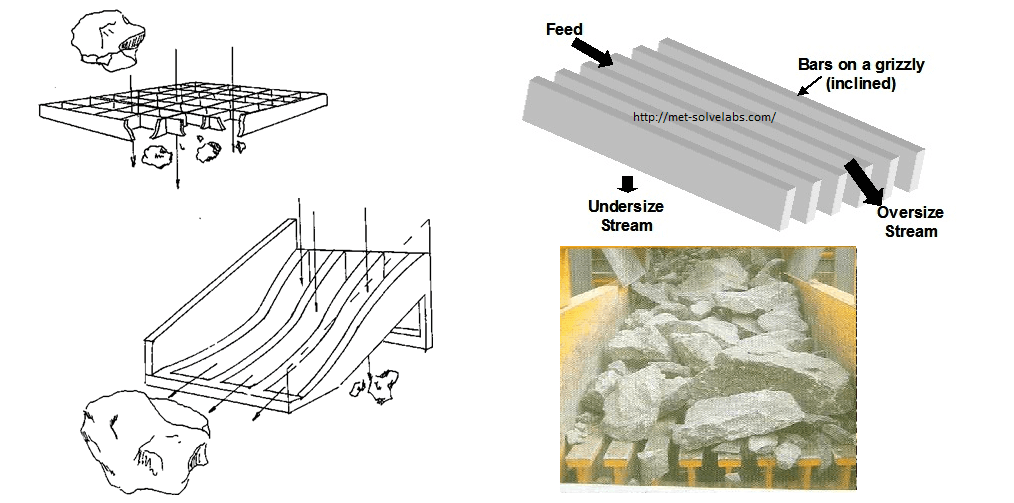

The screening a Static Grizzly separator does is sort and classify the rock according to size. The first stage is SCALPING. This is the practice of removing any material that may slow production. It may be rock that is too big for the equipment to effectively handle, or fine material that is taking up valuable space and will consume precious energy if there is further handling. The name of the equipment that performs this function is called a GRIZZLY.

The equipment is limited to a maximum size of rock that it can accept. The grizzly is a pattern of heavy steel bars that are laid down in a grid pattern. This grid will allow the small rocks to go through. The larger rock being bigger than the grid opening won’t. This rock then can be either sent for further size reduction, or removed.

Some grizzlies are placed on an incline. This will allow the large rock to he removed easily.

The purpose of this is to keep the grizzlies down time to a minimum by preventing the oversized rock from piling up while on its surface. The effectiveness of the sizing will be lowered due to rock that could go through sliding off. But as a counter balance the overall through put will be better due to the greater availability of the grid. If the Grizzlies performance rate is to low, then causing the grizzly to vibrate will increase the effectiveness of the sizing.

This below needs to be avoided and requires miners to not ship oversize to the crusher as it will kill tonnage and occupy the grizzly needlessly.

Grizzly Screen Design

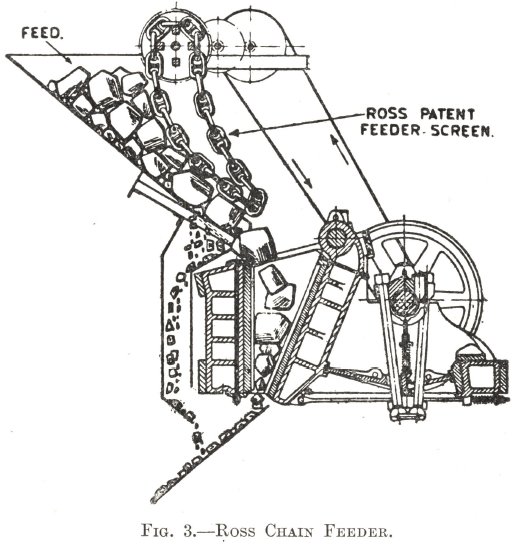

The Ross Chain Feeder illustrated in Fig. 3 is shown discharging the ore over a bar screen, or grizzly. It is advisable to provide a screen of this sort ahead of the primary breaker in order to bypass material that is already small enough to pass straight through the machine. The commonest device is a stationary grizzly from 6 to 12 ft. long, slightly wider than the stream of ore, and set at a slope of from 45° to 60° to the horizontal. The bars, which should be of mild steel, are preferably wedge-shaped with the wider part uppermost. They are held together by long bolts at right-angles to their length and are kept at the desired distance apart by spacing washers, which often consist of old piping cut to the required length. The clearance between the bars at the upper end should be the same as the discharge opening of the crusher which the grizzly serves, but at the lower end it should be slightly greater to prevent choking.

A grizzly of this type, though cheap and simple, tends to get clogged with ore. In conjunction with a Ross Chain Feeder, however, clogging is eliminated and the length of the bars can be reduced by 50% or more.

There are on the market several types of moving bar and ring screens designed to obviate choking, but none of them is used to anything like the same extent as the stationary bar grizzly.

Grizzly Bars

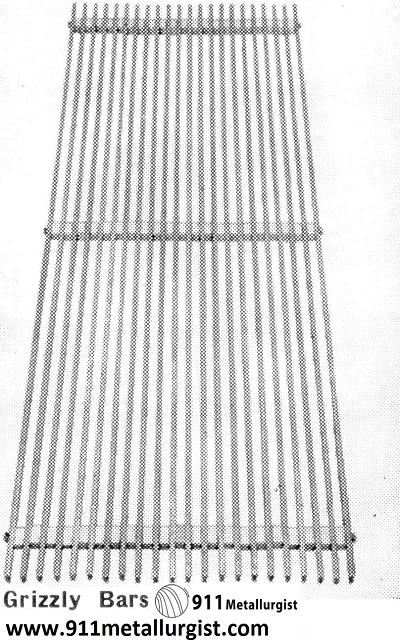

Bars are a widely used means of reducing the work of primary or secondary crushers. As the ore is fed to the crusher, it passes over the grizzly bars, and the finer pieces drop through into the mill ore bin. The grizzly is made of wear resisting wedge shaped bars easily replaced if necessary.

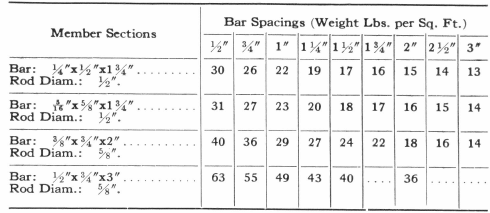

Grizzly Bars are punched and held in place by steel rods passing through the holes. Cast iron spacers, of the proper shape and width, are placed between the bars. Various types of bars and spacers can be supplied, depending upon the application.

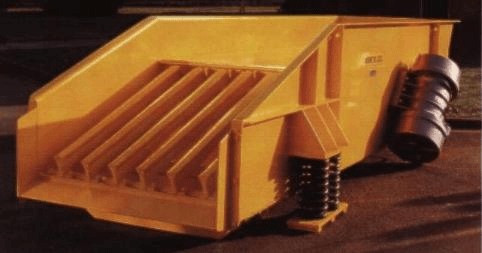

Vibrating Grizzly Screen

A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use. It combines the functions of screening and feeding the ore to the primary crusher, and, by eliminating the undersize product in the ore feed to the crusher, materially increases the crusher capacity. In addition, due to the pulsating action of the unit, the ore is fed positively to the crusher, at a controlled rate and the manual labor usually required is eliminated.

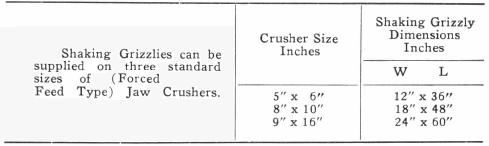

The unit consists of a strong, frame mounted, standard grizzly which receives a positive eccentric motion in a lateral plane through connecting links attached to the head motion of the jaw crusher. Due to this positive action the angle of slope of the grizzly may be much less than that required in fixed type grizzlies; and head room or fall may be reduced. The Shaking Grizzly is constructed in several sizes to fit standard Jaw Crushers.

Aggregate production plants use screens to direct, separate, and control material flow in the process. The two main purposes for screening the aggregates are to remove oversize material from the crusher product or undersize material from the crushing plant and to completely size the materials produced. An aggregate production plant must perform both functions.

The feed may contain some material that does not have to be crushed and which should be removed from the input to the primary crusher. A scalping unit is frequently used between the feeder and the primary crusher to remove from the feed material that is smaller than the setting of the crusher. It may be a grid, grate, or screen, and it may be stationary or it may víbrate. Raw material removed from the feed is sent to finish screens and reduction crushers.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.