Table of Contents

An environmental radiological survey was conducted on the El Paso Natural Gas Co. uranium tailings pile at Tuba City, Ariz., in May 1967, by the South-western Radiological Health Laboratory of the Public Health Service, U.S. Department of Health, Education, and Welfare (HEW). As the abstract of the reports of the survey summarizes the pertinent facts and findings, a verbatim copy is presented as a succinct description of the area and pollution problem:

The purpose of the survey was to evaluate any potential radiation hazards which exist and to recommend methods of control. The measurements and recommendations resulting from the survey are presented

- External gamma radiation on the mill tailings area averaged 0.7 mR/hr at three feet above the surface. This calculates to a yearly average dose of 6 rem for continuous exposure. This is 12 times the appropriate radiation protection guide (RPG) of 0.5 rem/yr for continuous whole body exposure to an individual in the general population.

- Wind carriage of tailings in an easterly direction past the property fence has resulted in elevated radiation levels. External gamma radiation at three feet above the surface within 1,000 feet of the property fence was of such a magnitude as to produce a yearly average dose equal to or greater than the RPG of 0.5 rem/yr for continuous exposure.

- The mill area exhibited external gamma radiation levels averaging 0.1 mR/hr at three feet above the surface. This calculates to a yearly average dose of 0.9 rem for continuous exposure or approximately 2 times the appropriate RPG of 0.5 rem/yr. With reasonable occupancy assumptions however the yearly average dose would probably not exceed 0.5 rem.

- The housing area displayed background levels of external radiation.

- Radon-222 concentrations in the atmosphere, with the exception of directly over the tailings pile, were found to be far below the appropriate radiation concentration guide (RCG) of 3 pCi/l. On the tailings pile itself radon concentrations are at or slightly below the RCG. It was found however that a low percent equilibrium existed between radon and its daughters.

- Airborne particulate sampling indicated significant radium-226 concentrations in the immediate downwind direction from the pile. Levels of approximately three times the RCG of 200×10 -55 pCi/l for insoluble radium were found 200 feet east of the mill property. Thorium-230 concentrations were estimated to be approximately 10 times the RCG of 8×10 -5 pCi/l 200 feet east of the mill property.

- At the present time there appears to be no contamination of surface or ground water in the surrounding area from leaching of radioactive materials from the tailings area.

On the basis of the data gathered in this survey it is recommended that the mill tailings be properly stabilized against wind erosion. This action would preclude further carriage of tailings material into the surrounding environment and would eliminate the potential long-term hazard to anyone inhabiting the area downwind from the mill property.

As a result of the external radiation levels on the tailings area itself, this area should not be released for public use in its present state. Action which would permit release of the area would be to cover the tailings with uncontaminated dirt to an extent that would diminish the external radiation to an acceptable level and to stabilize the covering against wind erosion. Otherwise, the area should be fenced and controlled as a radiation area.

Based upon this report, El Paso Natural Gas Co. at the suggestion of the Arizona State Atomic Energy Commission asked the Bureau of Mines Salt Lake City Metallurgy Research Center (SLCMRC) for assistance in devising a satisfactory and a reasonable cost method of stabilizing the uranium wastes. As the SLCMRC was developing and evaluating different means for stabilizing mineral wastes under the Solid Waste Disposal Act of 1965, an investigation was initiated to devise a stabilization method suited for the particular conditions involved.

Acknowledgments

The authors gratefully acknowledge the contributions of Dr. S. D. Shearer and Robert N. Snelling of the Southwest Radiation Health Laboratory for their report delineating the conditions of the waste pile. Acknowledgments are also made to W. T. Hollis and Harold Horst of the El Paso Natural Gas Co. and to Lynn A. Fitzrandolph of the Arizona State Atomic Energy Commission for full assistance and cooperation during the stabilization study.

Environmental Considerations

The Tuba City uranium mill tailings are located on the Navajo Indian Reservation approximately 6 miles east of Tuba City, Coconino County, Ariz. The sparsely vegetated land surrounding the tailings is used by the Indians primarily for cattle and sheep grazing. The nearest natural water source is the Moenkopi Wash, approximately 2 miles south of the property, which contains water for 11 to 12 months of the year. Few persons live in the environs of the waste area.

Tuba City and nearby areas are about 5,000 feet above sea level. The climate is relatively harsh. Meteorological data show a record temperature of 110° F, and summer daytime temperatures often reach 106° F. Temperatures as low as -15° F have been recorded, and during an 8-year period the temperature fell below freezing in each month except June, July, August, and September. The normal annual precipitation for Tuba City is 6.49 inches. In a representative period from 1951 through 1960, the rate varied from a low of 3.34 inches in 1956 to a high of 13.25 inches in 1952.

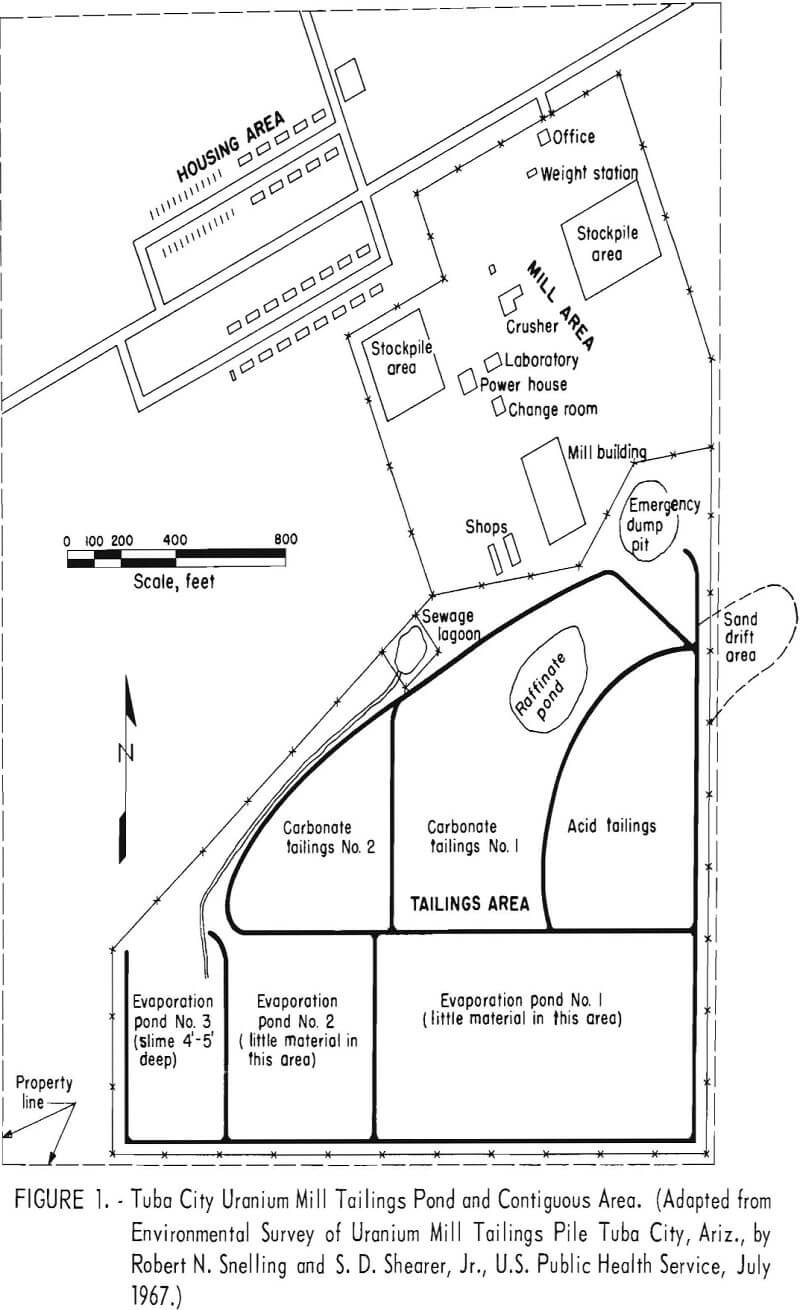

Figure 1 is a generalized illustration of the tailings and contiguous area involved in this study. The dotted line shows a fence added upon completion of stabilizing the area to restrict access to the stabilized plot. The area of the carbonate Nos. 1 and 2 and acid tailings ponds is about 34.5 acres.

The acid tailings were piled to depths ranging from 20 feet above the surrounding land at the northeast to depths of 50 feet on the south and east. The sand drift area covered about 3 acres extending approximately 500 feet from the main body of tailings and tapering at the outer edge to depths of less than 0.25 inch. The pH values of the acid leach tailing were as low as 2.3. The tailings in the carbonate No. 1 pile were deposited to depths ranging from ground level on the north to 65 feet deep on the south. The pH values of the carbonate No. 1 tailings varied from 7.4 on the perimeter to 9.2

in the center of the pond, and the carbonate No. 2 tailings had a pH value of 9.5. A dike about 10 feet high separated the carbonate No. 1 and the acid tailings pond, and a 15-foot ridge separated carbonate piles Nos. 1 and 2. Carbonate No. 2 pile was surrounded by a dike of country rock and soil ranging from a height of 5 feet in the north to 20 feet at the south. The bowl formed contained fine tailings to a maximum depth of approximately 10 feet at the southern side. Evaporative ponds Nos 1 and 2 contained little material whereas No. 3 contained approximately 4- to 5-foot depths of indurated clay-like material apparently not subject to wind erosion.

The uranium mill was originally operated on an acid circuit; later a sodium carbonate leach system was used. The acid pile was deposited first with the fine-sized material overflowing to the base of what is now called carbonate tailings No. 1. Upon conversion to a carbonate system, the tailings were discharged into carbonate tailings No. 1 with progressively finer sized materials overflowing to carbonate tailings No. 2 and, finally, to evaporation pond No. 3. Thus, the acid and carbonate No, 1 tailings areas were relatively sandy, the carbonate No. 2 tailings were of finer size and intermixed with sodium carbonate salt, and evaporation pond No 3 contained extremely fine- sized slime material.

Determination of Stabilization Approach

The Bureau of Mines has been investigating several means for stabilizing relatively fine-sized wastes, such as those on the Tuba City property, which are sources of air and water pollution. These methods include physical, chemical, and vegetative stabilization, and combinations thereof, Massive coverings of coarse slag, concrete, soil, and bark plus properly used straw, auto tires, brush, etc. may be used to prevent erosion of waste piles. A variety of chemicals can be used to bond the particles of fine-sized waste into a relatively inert mass., Vegetative and combined chemical-vegetative stabilization also hold promise for preventing or reducing erosion as well as producing esthetically appealing tailings storage sites. Vegetation is especially appealing in that the protection is renewable.

Vegetative procedures were deemed unsuited because of the climate and the basic and acidic nature of the tailing materials. The precipitation rate of 6.49 inches per year was exceptionally restrictive. A. C. Hull in his study of seeding rangelands designates areas receiving less than 9 inches of precipitation per year as harsh sites. He predicts that, even though careful planting is employed and other conditions are favorable, failure can be expected in about 1 year out of 3.

Physical stabilization using country rock and soil coverings was considered impractical on a cost basis. Cost estimates obtained from several sources for digging, short haulage, and placing a 12-inch soil cover ranged from $0.23 to $0.36 per square yard. An Arizona copper producer with experience in covering two copper mill tailing ponds and an HEW report estimating the cost for burying uranium mill tailings agree on a cost of $0.23 per square yard for digging, short hauling, and placing a 12-inch soil cover. This would amount to $1,113 per acre exclusive of costs for soil procurement.

An inspection of the Tuba City tailings revealed several soft sections that would hamper the use of heavy equipment and add to cost of placing the cover. In addition, costs for procuring soil not available on the site and hauling soil to the site would further increase the cost of soil covering.

Comparative cost estimates indicated chemical stabilization methods to be much less expensive than soil covering of these mill tailings. As stabilization against wind erosion was the principal objective, a search for suitable chemicals for the Tuba City wastes was initiated. Fine-sized wastes have been effectively stabilized in both the laboratory and field by application of reagents costing as little as $0.01 for a quantity to cover a square yard with application costs of approximately the same magnitude.

A survey made by El Paso Natural Gas Co. and Bureau of Mines personnel indicated the following:

The dikes of the tailings ponds were formed from sand fractions cycloned from the tailings. The dike material was laid down in an irregular manner, and some cyclone discharge piles were 10 to 15 feet above the general level of the dikes. These dike piles plus the acid and carbonate No. 1 wastes constituted the principal erosional problem areas. Carbonate No. 2 wastes, while not subject to extensive wind erosion, did show evidence of an efflorescing salt crust.

The following actions were deemed necessary if effective control of the tailings area were to be achieved:

- Return of the sand drift area material to the confines of the fenced tailing ponds.

- Leveling of the dikes to eliminate irregularity of outline to decrease wind erosion.

- Stabilizing the dikes and beaches of the acid and carbonate Nos. 1 and 2 tailings with properly selected chemicals,

- Erecting an additional fence line on the north of the tailings to more closely circumscribe the area

Selection of the most desirable chemicals for application to the specific dike and beach problem areas became the principal laboratory research target.

Chemical Testing

Many chemicals had been tested and evaluated at the SLCMRC on other mineral wastes prior to considering the Tuba City tailings problem. Among the materials tested were lime; pyrite, sodium silicate with varying ratios of SiO2 to Na2O, silicates with FeSO4 and CaCl2 additives, various lignosulfonates, redwood bark extracts, amines, acetate salts of amines, dicalcium silicate, bituminous base products, elastomenc polymers, and resinous adhesives.

Reagents for testing on the Tuba City wastes were selected from some of the better reagents determined from prior testing. These included Coherex, a resinous adhesive; DCA-70, cationic neoprene emulsion, SP-400, Rezosol, and Soil Gard, elastomeric polymers; Landscape, a product derived from sulfonated petroleum; Peneprime, a cutback asphalt product; and various calcium sodium, ammonium, and mixed lignosulfonates, including Norlig A of the calcium type.

These reagents were applied to the tailings in quantities costing 1, 2, 4, and 8 cents per square yard. Separate indoor and outdoor test plots 6 by 6 inches and 14 by 28 inches in size, respectively, were established as representative of both acidic and basic tailings in sand and slime size fractions.

Samples of indoor tailings plots treated with the various quantities and types of reagents were subjected to simulated winds ranging from 20 to 80 mph for 5-minute periods in a wind tunnel. The coherency of the surfaces was comparatively evaluated as to wind erosion resistances by measuring the total quantity of tailings lost while subject to the wind forces created in the wind tunnel. The resistance to water erosion was comparatively evaluated by subjecting the samples to a fine jet of water at 5 psi pressure. The water jet was applied to the various samples for a 1-minute period. If no appreciable penetration of the surface was obtained, the time was extended to 2 minutes, then to 5 minutes. If penetration still had not been obtained, the pressure was increased to 10 psi and the time intervals repeated until a marked penetration of the surface was noted. Outdoor samples were subjected to the natural weather elements of high and low temperatures, rain and snowfall, and prevailing wind conditions during the testing. A comparison of the variously treated samples at the conclusion of the testing period enabled selection of two preferred chemicals.

The two chemicals selected for application to the Tuba City tailings were DCA-70, an elastomeric polymer manufactured by Union Carbide Corp, and Norlig A, a calcium 1ignosulfonate produced by American Can Co. DCA-70 had the properties of good penetration (approximately 2 inches) through sandy materials and of becoming water insoluble after emplacement. Thus DCA-70 was selected for placement on the relatively steep sloped sandy dikes that bore the brunt of the water and wind erosion. The minimum quantity of DCA-70 required to form a suitable crust was 0.047 gallon per square yard at a cost of 8 cents per square yard of dike treated. Norlig A, a calcium magnesium lignosulfonate, produced an extremely hard surface crust on both the acid and the carbonate ponds. It was the only chemical tested that produced durable wind resistant crusts on the carbonate tailings. The minimum amount required was determined to be 1 pound of dry powder per square yard, added as a 10-percent water solution, equivalent to a reagent cost of 4 cents per square yard of tailings treated.

Laboratory tests also were conducted to determine if use of the chemical stabilizers reduced the emission of radon gas from the radioactive tailings. Tests by another group within the SLCMRC showed that 2 feet of soil as used on the radioactive mill tailings at Monticello, Utah, does not prevent the emission of the radon and most chemicals applied in moderate quantities are ineffective. For example, almost ¼-inch thickness of asphalt roofing tar was applied before the radon gas emissions were materially reduced. When applied to laboratory samples in quantities equivalent to those to be emplaced on the Tuba City tailings, the two chemicals proved ineffective in retarding radon emissions. A slight increase in radon emission was noted when measurements were made within 2 to 4 days after application of the chemicals, but after 7 to 10 days the emission returned to within the normal standard of deviation range. The initial increase in emission was ascribed to the addition of water to the tailings and the capillary movement of this water to the surface.

Onsite Application of Chemicals

Vehicles and heavy equipment are subject to miring down in tailings ponds containing appreciable quantities of slimes. Therefore, means were sought for spreading the chemicals without using heavy equipment. Of several different types of equipment available, a traveling sprinkler designated as the Model 400 Rain Train, manufactured by L. R. Nelson of Peoria, III., was selected for use. The self-propelled Rain Train weighs only 60 pounds. A rope is stretched from a reel on the front of the sprinkler and the free end staked at a distance up to 400 feet along the desired direction of sprinkling. Water pressure via a hose attached to the rear of the machine propels the sprinkler as directed by the rope to give an even distribution of water on each side of the sprinkler up to a radius of 65 feet. The extent of coverage is dependent upon the sprinkler head, pressure, and nozzle diameter used.

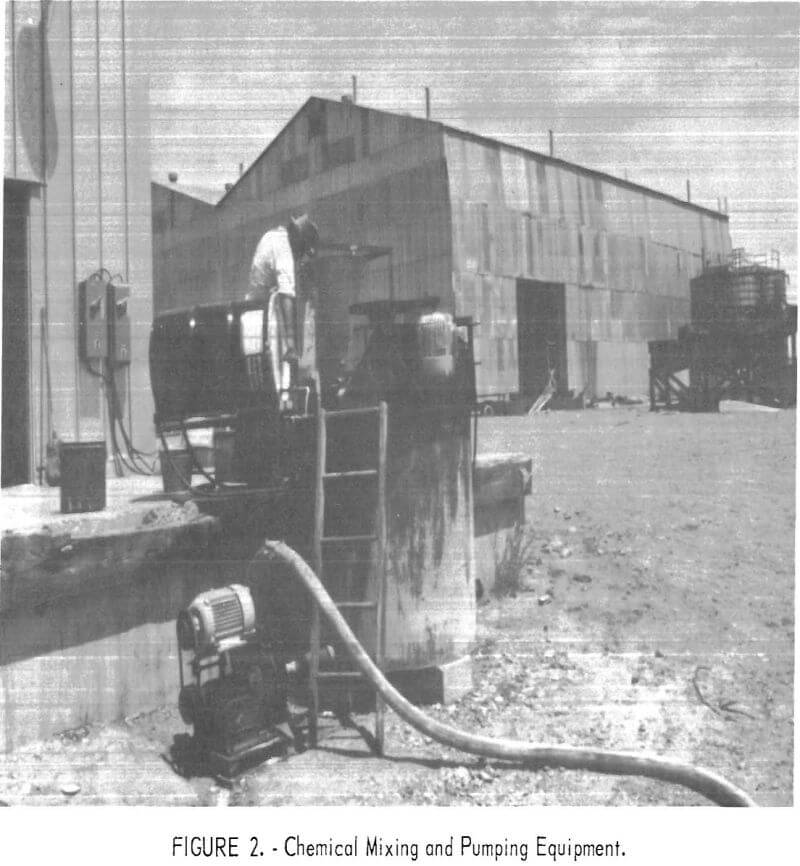

For the Tuba City tailings application each chemical was mixed with water in a 4- by 4-foot agitator. The resulting chemical solution was propelled by a rubber-lined centrifugal pump through a 3-inch fire hose, up to 1,300 feet from the tank, to a connecting 200 feet of 1-inch hose attached to the sprinkler. The pressure was approximately 40 psi at the sprinkler. The gallons per minute of solution applied were determined by a water meter installed in the line from the fire hose to the sprinkler. Figure 2 shows the agitator mixing of the chemical. Figure 3 depicts the sprinkler in operation on the Tuba City ponds.

Approximately 6.5 acres of dikes were sprinkled with a DCA-70-water solution. The amount of chemical deposited per unit area was varied in accordance with the susceptibility of the area to wind erosion. Differential coverage of all tailings was satisfactorily achieved by varying the strength of the DCA-70 solution between 3.5 and 6.5 percent and using three different sprinkling

heads and orifice sizes. Solution quantities applied varied from 0.045 to 0.068 gallon DCA-70 per square yard for reagent costs varying from 8 to 12 cents, respectively. The average rate of application was 0.053 gallon, equal to a reagent cost of 9.03 cents per square yard of treated dike.

Twenty-eight acres of beaches were treated with Norlig A. The Norlig A (a dry powder) was dissolved in the agitator tank to produce solution strengths controlled at 5 to 10 percent. The chemical was applied at rates and costs varying from 0.9 to 1.2 pounds and 4.3 to 5.8 cents per square yard, respectively. The average amount of chemical applied was 0.93 pound per square yard which is equivalent to a cost of 4.5 cents.

Observation of Results

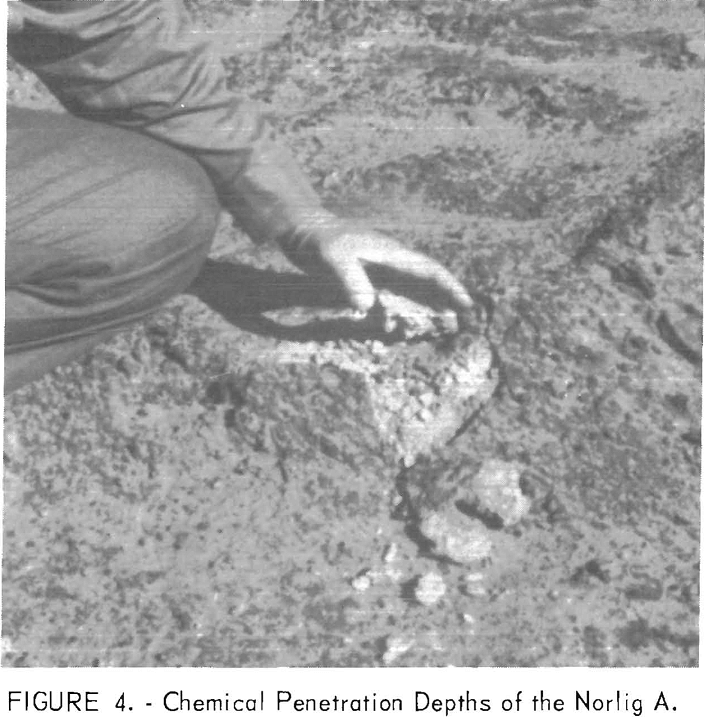

The chemically stabilized Tuba City tailings were examined by personnel of the Arizona State Atomic Energy Commission, El Paso Natural Gas Co., and the Bureau of Mines on October 2, 1968, approximately 2 weeks after application of the last of the chemicals. This examination disclosed that the Norlig A and DCA-70 had penetrated into the tailings up to depths of ¾ inch and 2 inches, respectively. The crusts were indurated, especially those of the Norlig A treated sections, which required considerable pressure on the tip of a knife blade to secure any penetration. Figure 4 depicts the chemical penetration depths of the Norlig A. Considerable foot traffic on the piles during the inspection did not materially affect the coherency of the crust. All surfaces appeared capable of resisting wind erosion, a conclusion substantiated by observation during several subsequent wind storms which indicated no wind erosion.

Cost of Treatment

Costs for stabilizing different milling wastes vary greatly depending upon the location, terrain, acreage, and type of stabilization employed at each specific site. The Bureau of Mines and Kennecott Copper Corp. cooperated in stabilizing a 10-acre test plot of copper tailings in Nevada without soil cover by a combined chemical and vegetative method at a cost of $135.50 per acre. Arizona copper producers and HEW report that the costs for placement of a 12-inch soil cover were about $1,100 per acre. Stabilization of the Monticello, Utah, uranium wastes by deposition of up to 24 inches of country soil and vegetative planting cost almost $5,000 per acre. The Monticello stabilization work entailed considerable moving of tailing sands for consolidation and new contouring.

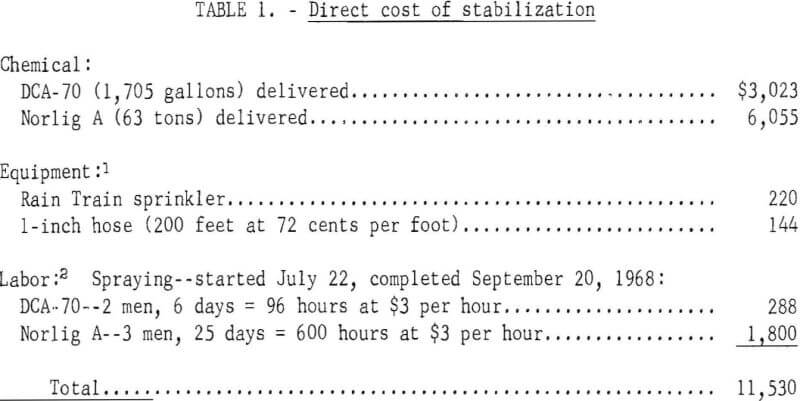

The direct costs incurred for equipment, labor, and chemicals used to stabilize 34.5 acres of Tuba City tailings are given in table 1. These costs do not include indirect costs for supervision and overhead or the $2,100 expended by El Paso Natural Gas Co. for leveling dikes and returning windblown sand, signs, and fencing.

The $11,530 cost of chemically stabilizing the 34.5 acres of tailings at Tuba City indicates a per acre cost of approximately $335. The DCA-70 and Norlig A chemicals were shipped from Charleston, W. Va., and Neenah, Wis., respectively. Freight costs were over $1,200, of which about $800 was for trucking the chemicals from Flagstaff to Tuba City.

Conclusions

- Physical, vegetative, and chemical procedures for stabilizing Tuba City, Ariz., acidic and basic uranium mill tailings were evaluated. Physical and vegetative procedures were eliminated from consideration because of adverse cost and climatic conditions.

- Over 20 chemicals were tested for producing surfaces resistant to wind erosion. DCA-70, an elastomeric polymer, and Norlig A, a calcium ligno-sulfonate chemical, were selected for application to the dikes and beaches, respectively.

- DCA-70 and Norlig A, both water soluble, were applied using an auto¬mated self-propelling sprinkler to produce indurated crusts resistant to wind erosion.

- The direct cost for stabilizing the 34.5-acre tailing pond was about $335 per acre.