Table of Contents

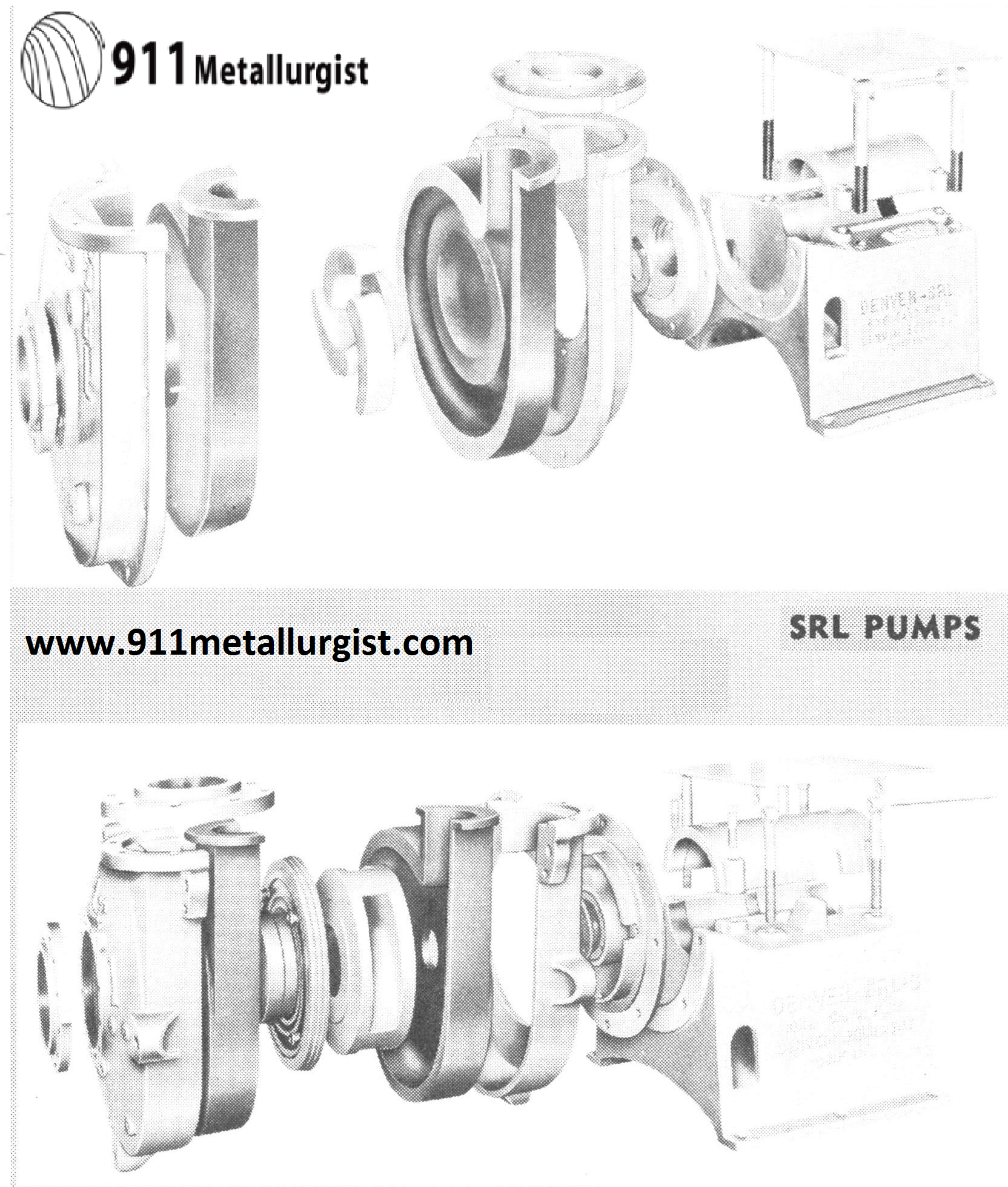

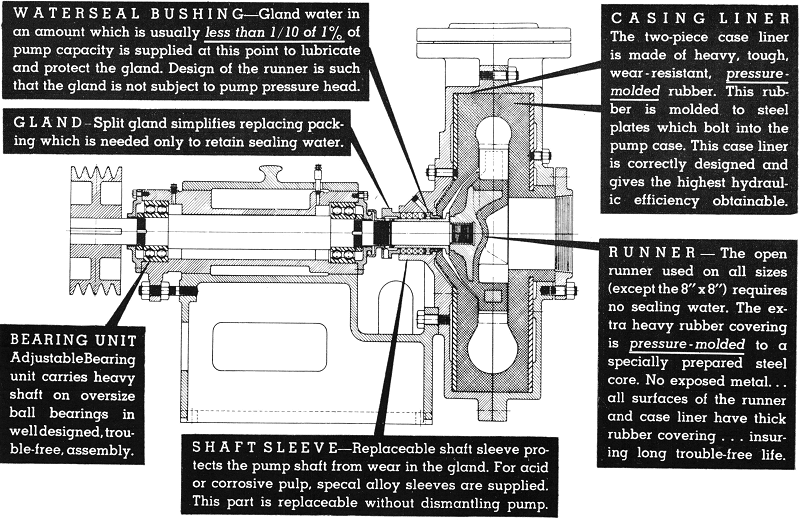

SRL SAND PUMPS —GLAND TYPE

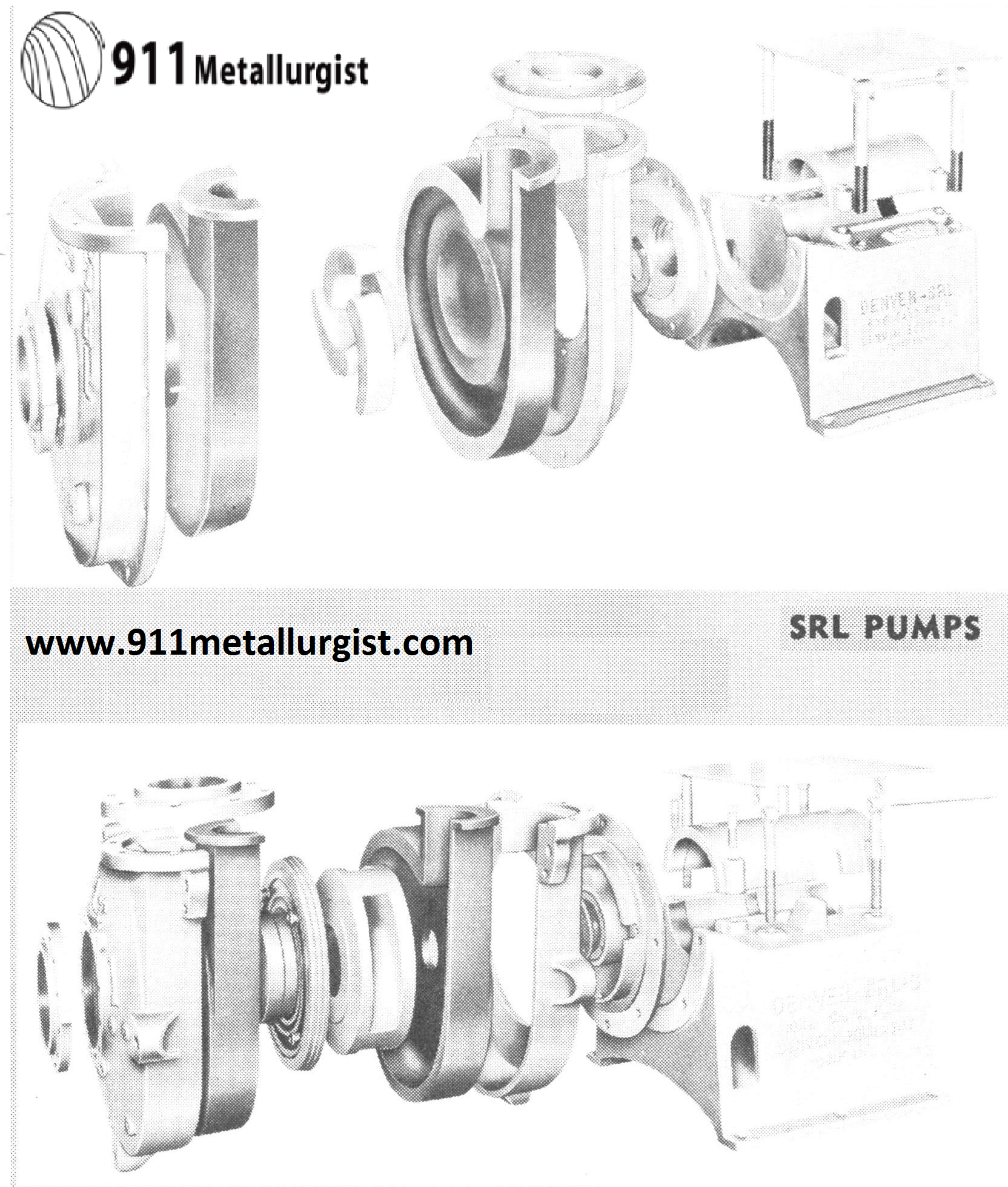

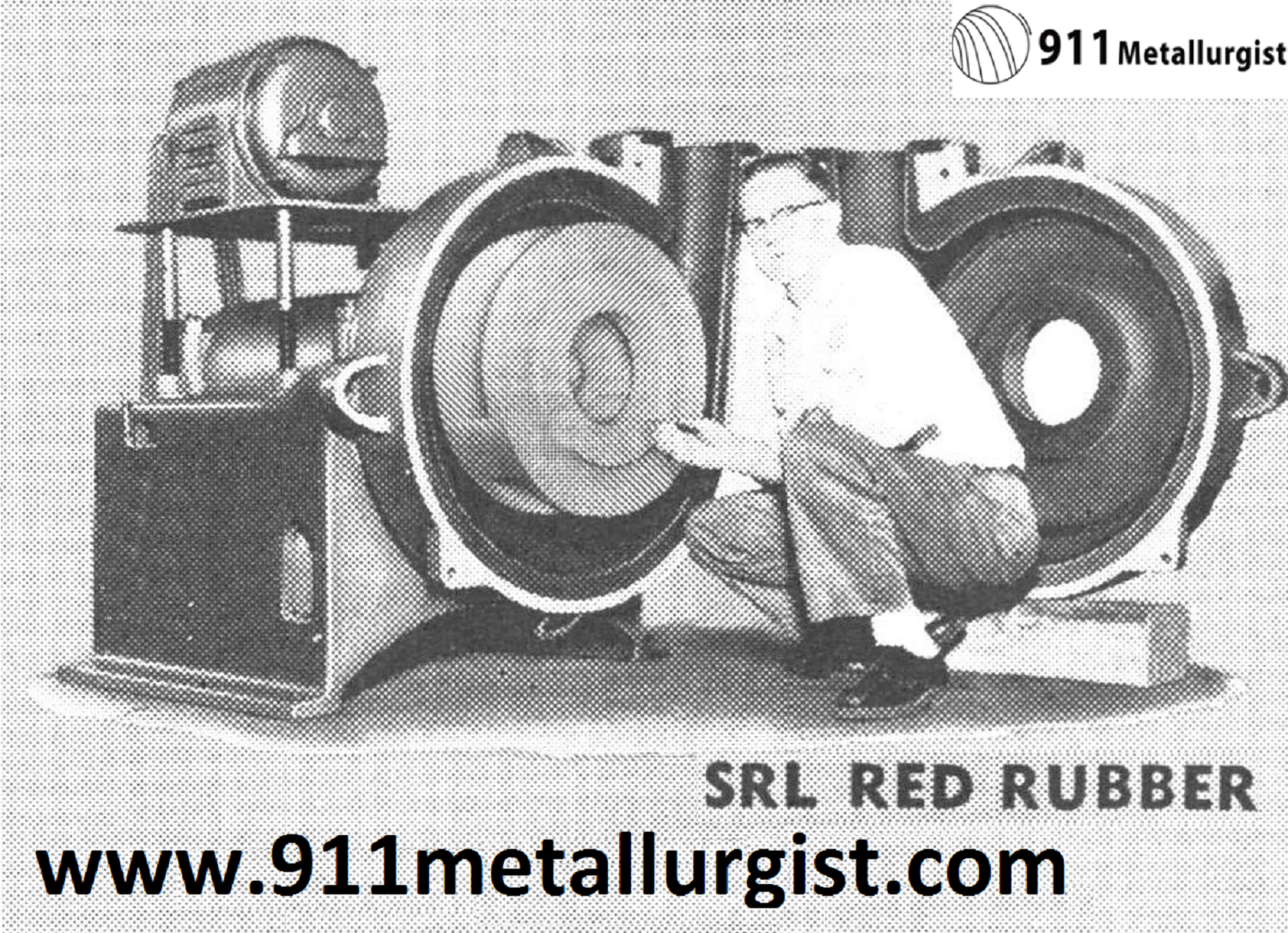

SRL Pumps with positive Water Seal have a world-wide reputation for their high efficiency, low part cost, long life in handling abrasive slurries, sands and acids. Wear causes loss of pump efficiency and loss of pressure. Accuracy of parts, precision molded of rubber, and the superior wearing qualities of the tough “dense” rubber used in SRL Sand Pumps keeps efficiency high over an extended period of service. High pumping efficiency also results in lower horsepower requirements. Parts cost less because they last much longer than those of other pumps. Positive gland water seal protects shaft, yet sealing water requirements are so small that changes in slurry density between pump feed and discharge cannot be measured. Mechanical seals are also available. Tough SRL Red Rubber runners and casing liners are standard on all SRL Pumps. Other polymers are available for applications involving high temperatures, oils or acids where abrasion is a secondary problem. Fittings of stainless steel, Hastelloy, Decolloy and other machineable alloys are also available. Sizes to 5000 GPM.

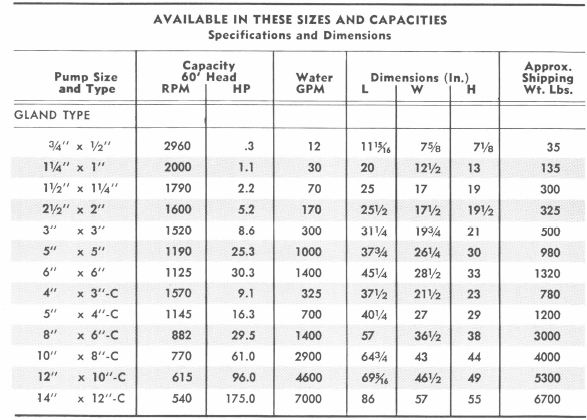

SRL SAND PUMP Capacity

SRL SERVICE CRANE

The SRL Service Crane is available as an accessory to be used on all larger SRL Pumps. Simple, portable, low-cost. Provides additional safety, speeds replacement service. Can be attached to pump or one unit will serve several pumps.

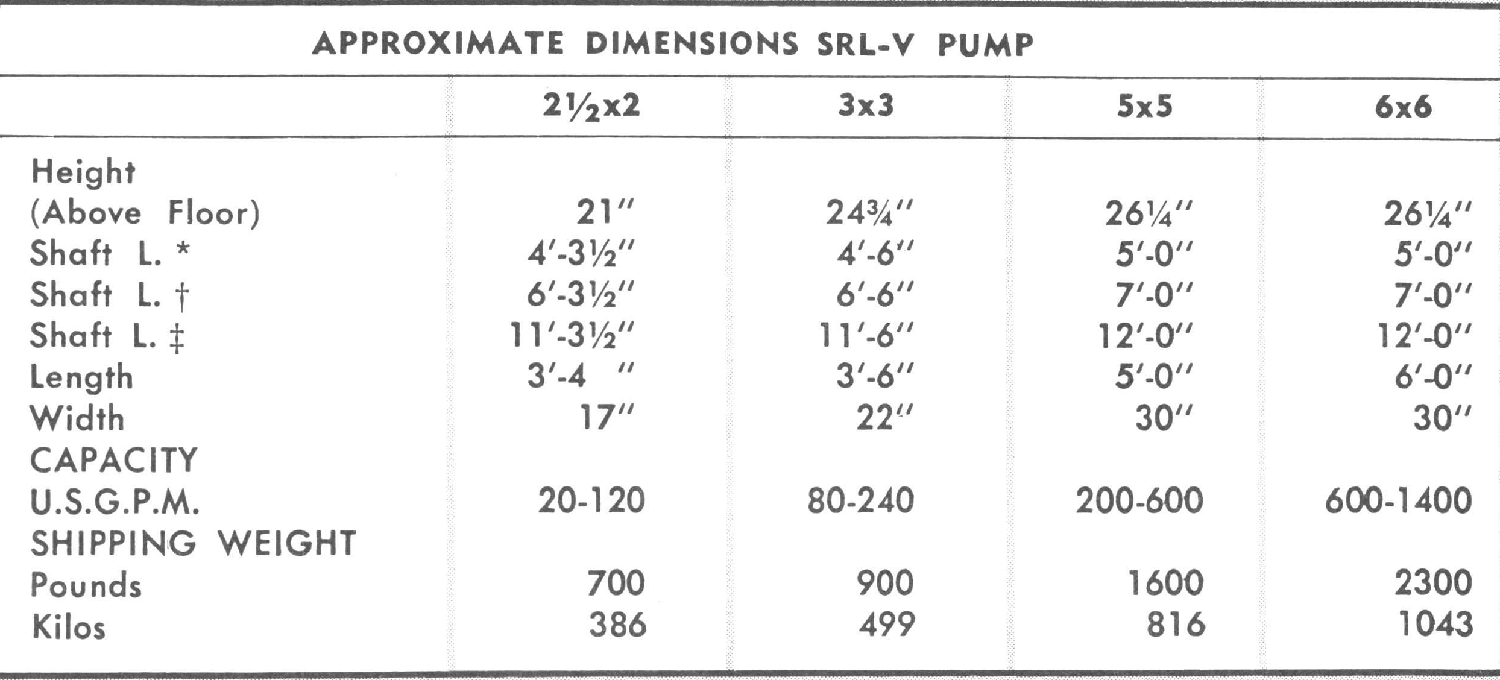

SRL-VERTICAL SUMP PUMP

Gives you all the sizes and advantages of SRL Sand Pumps for high efficiency, reduced power requirements, long part life, low cost pump service. Anti-friction bearings at top of shaft are well above sump level, lower bearings are marine type, water lubricated, Cutlass bearings, famous for long life and trouble-free service.

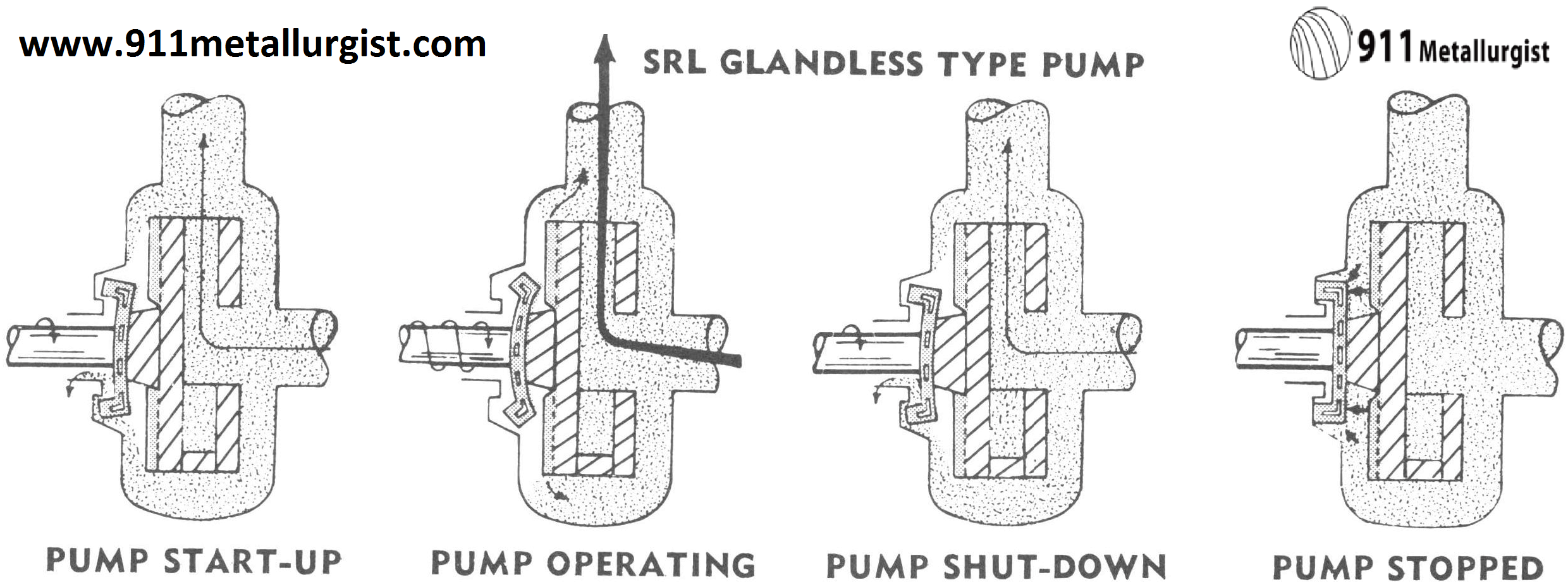

SRL SAND PUMPS — GLANDLESS TYPE

The SRL Glandless Type Pump is a companion to the SRL Pump which has a water-lubricated gland. The Glandless Type Pump provides the recognized long-wearing qualities of the SRL Pump in operations the requirements of which prohibit addition of gland water into the pulp stream.

HAS NO GLAND-NO SEALING WATER REQUIRED

Unlike other “seal-less” pumps, the pump has no gland, no packing and eliminates pulp dilution. The only mechanical action is the movement through centrifugal force of a steel spring molded in rubber labyrinth collar. The diagrams below picture the action of the seal. Because there are no mechanical linkages or devices to get out of adjustment, or to wear, maintenance-free operation is maintained through start-ups and shut-downs without fear of losing the sealing action.

DOUBLE MECHANICAL SEAL

The SRL-Double Mechanical Seal consists of two spring-loaded seals, an outer and an inner seal. A cooling and lubricating solution is introduced between the seals but does not dilute the material being pumped.

SINGLE MECHANICAL SEAL

The SRL Single Mechanical Seal arrangement is a standard single mechanical pump seal. It is applicable to non-abrasive corrosive solutions.

WIPER SEAL

The SRL Wiper Seal arrangement consists of two neoprene seals which are lubricated by either grease or solution. Wiper seals are applicable to non-abrasive corrosive solutions.

PACKED SEAL

The SRL Packed Seal arrangement provides Multiple row pump packing. It may be grease lubricated and is applicable wherever a packed pump can be used.

SRL Red Rubber, a special abrasive resistant, tear resistant stock, is standard on all SRL and SRL Glandless Type Pumps. This Red Rubber is especially suited for pumping abrasive grinding mill discharge to cyclone classifiers where coarse particles (up to ¾”) normally would be a problem. Tough, live SRL Red Rubber outwears, outlasts, out-performs generally-used gum rubber and allows SRL Rubber Lined Pumps to be used where metal pumps have previously been considered necessary.

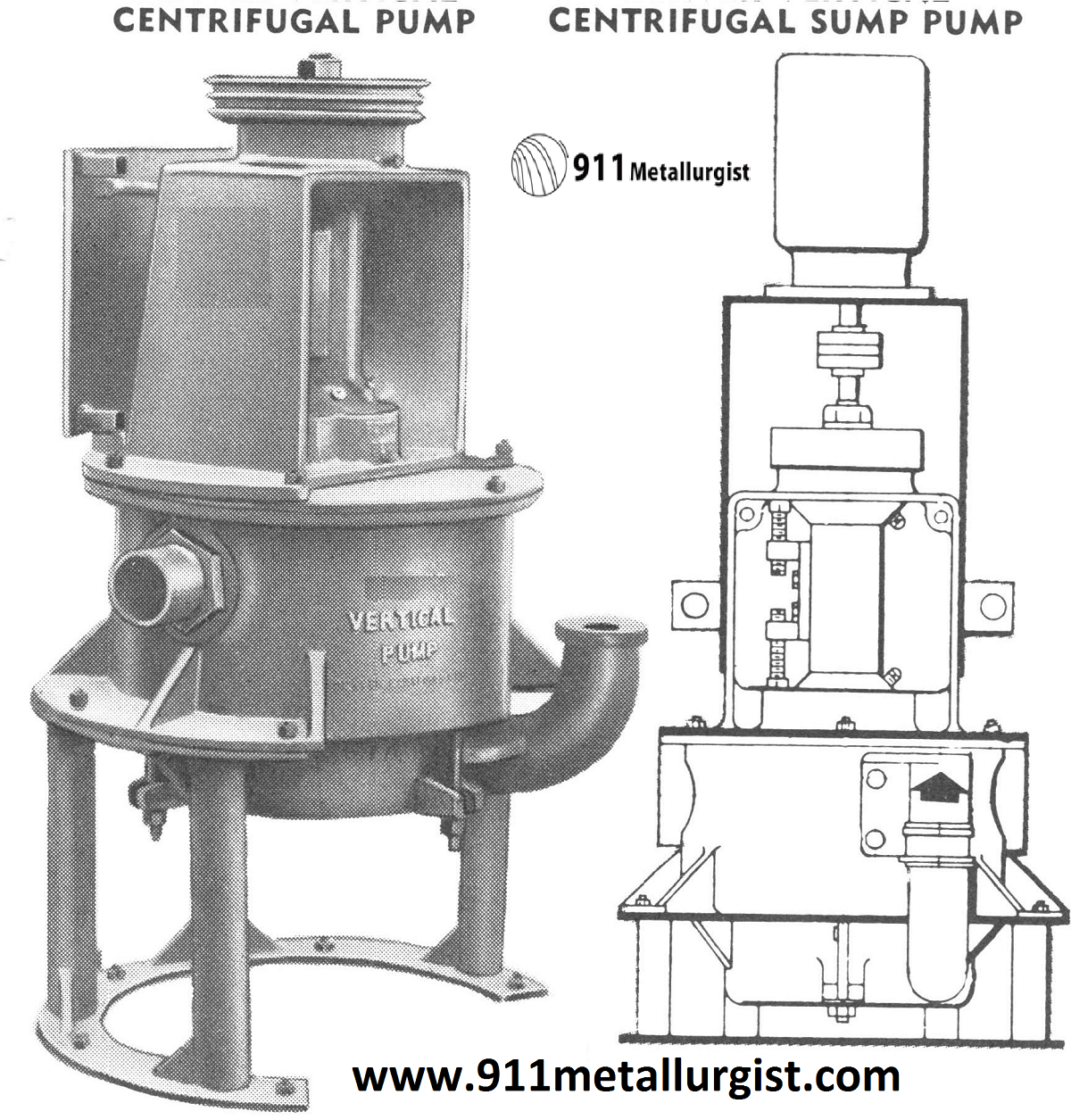

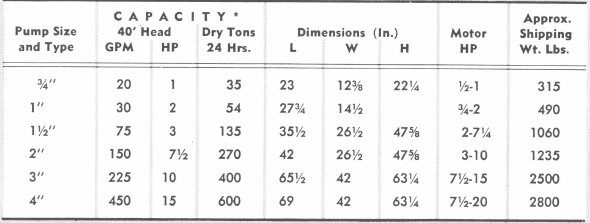

VERTICAL CENTRIFUGAL PUMPS

Ideal for handling frothy liquids or coarse sandy slurries. Handles any material that will flow by gravity. No sump or feed box is required. Self priming, no sealing water required. Vertical design eliminates gland. Handles intermittent flow. Long service from wearing parts. Pump can be run dry without danger. Available with rubber wearing parts, steel, or in stainless steel construction for acid service. Capacities to 450 g.p.m. Write for Bulletin No. P10-B5. Laboratory size Vertical Pumps available.

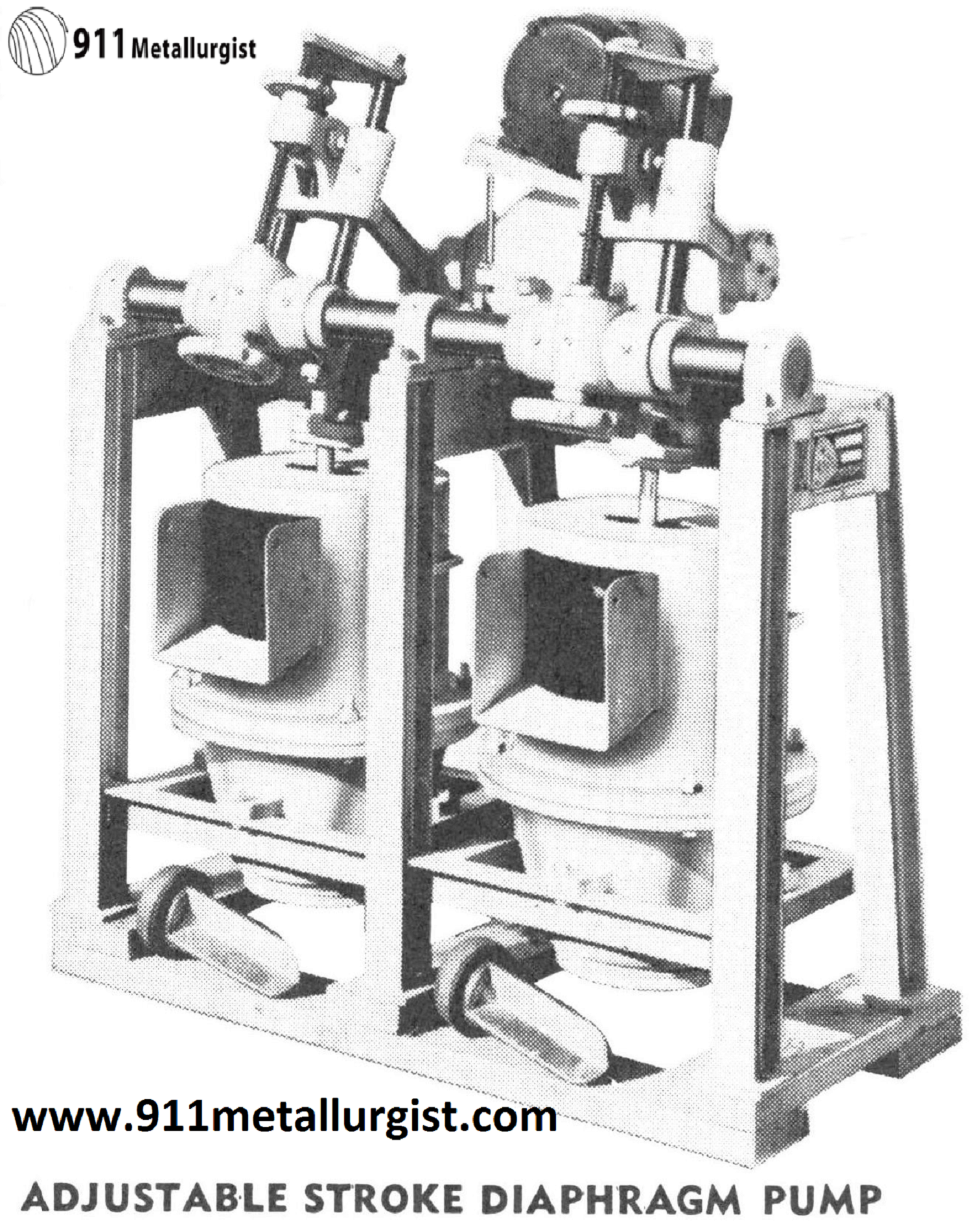

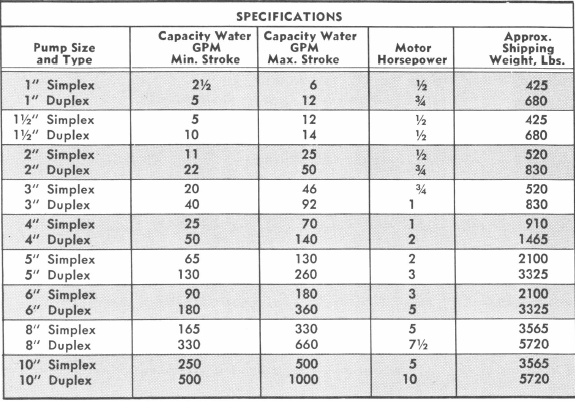

ADJUSTABLE STROKE DIAPHRAGM PUMP —MODEL E

Ability to adjust stroke while pump is operating makes pump particularly valuable for handling and metering thickened or high specific gravity slurries. Large specially shaped nylon reinforced rubber diaphragm gives long life. Low head design. Anti-friction bearing construction. Optional ball or bayonet valves. Rubber covered and stainless steel construction available. Sizes 1″ to 10″, Simplex and Duplex, capacities to 1000 g.p.m. Write for Bulletin No. P8-B12.

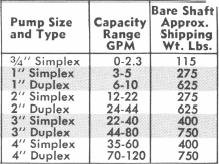

SUCTION PRESSURE PUMPS

Solve special problems where elevation is involved. Ideal where metered flows are required. Variation of stroke is possible with adjustable eccentric. Available in acid-proof construction if required. Rugged construction makes this pump valuable in many difficult jobs.

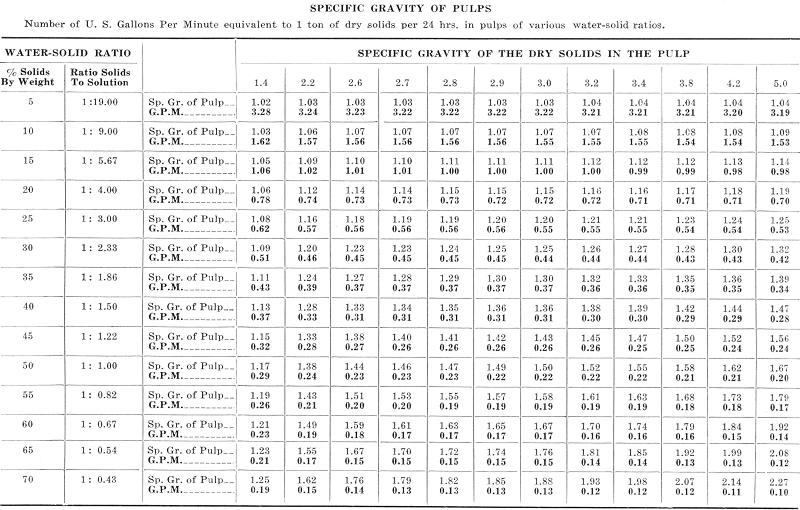

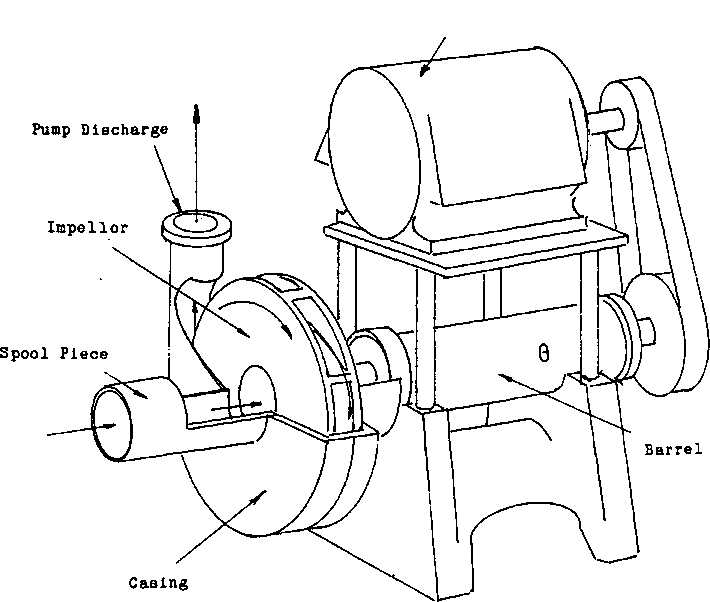

SRL Sand Pumps

Higher Mechanical Efficiency

During the past few years the SRL (soft rubber lined) pump has become standard equipment for handling abrasive pulps in the mining industry. This is because of its outstanding performance record.

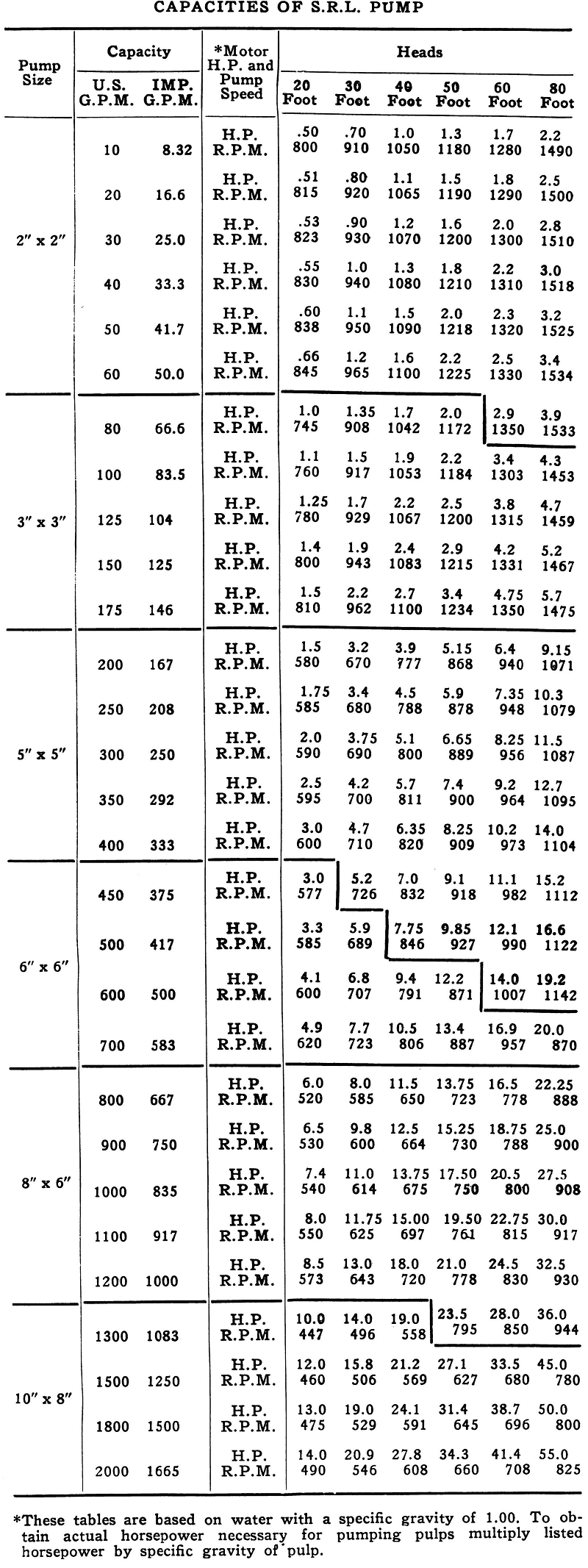

The design of the impeller and casing of the SRL pump is such that high mechanical efficiency is obtained. The accurately formed molded rubber parts allow very small clearance and this clearance is maintained during the life of the wearing parts. As there is practically no wear on the impeller, it is operated at the proper speed for the head and volume being pumped and is not run at a higher initial speed to compensate for later wear and loss of diameter. Efficiencies of from 50% to 75% are common with the SRL pump. The efficiency obtained in a given installation depends on the volume and head. At maximum capacity the pump has its highest mechanical efficiency.

30-70 Per Cent Power Saving

The power required for SRL pumps for various head capacities is 30 to 70 per cent of that of other pumps on similar service. In some cases, the saving in power alone, can pay for the SRL pump in a short time. In addition, there is usually a difference of several hundred dollars a year in repair and maintenance cost.

The practice of having a standby pump has been discontinued wherever the SRL pump is installed. Wearing parts can be changed in a very few minutes, and this is only necessary at intervals of a year or more.

All sizes are built with open type impeller except the 8″x 6″ and 10″x 8″ and these have the closed type. The open runner is standard on the 3″x 3″, but a closed runner can be supplied.

SRL Capacity

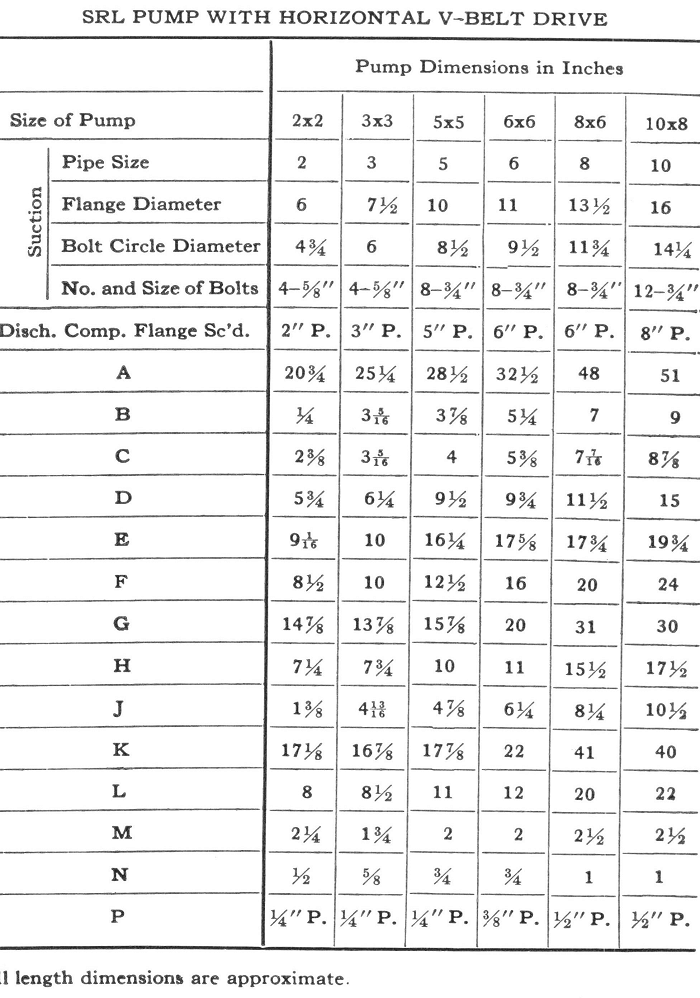

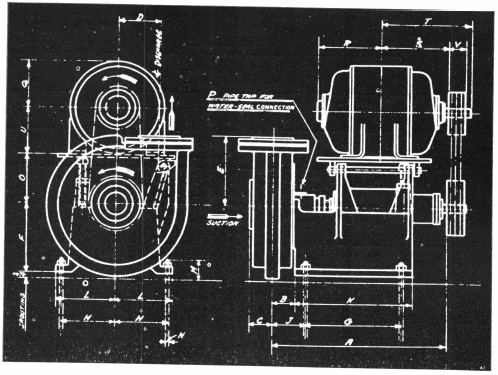

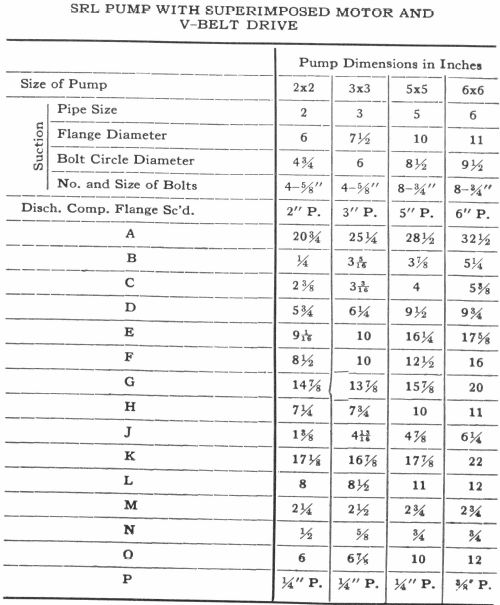

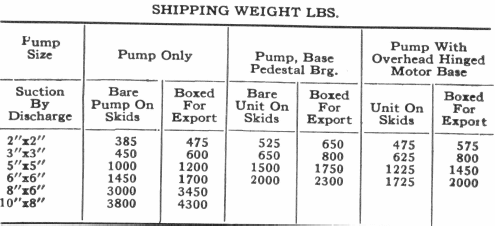

SRL Sand Pump Specifications

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.