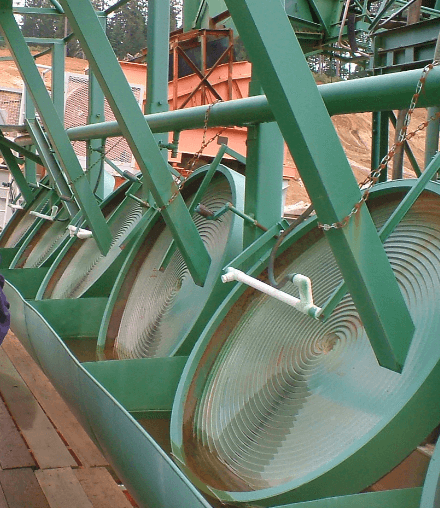

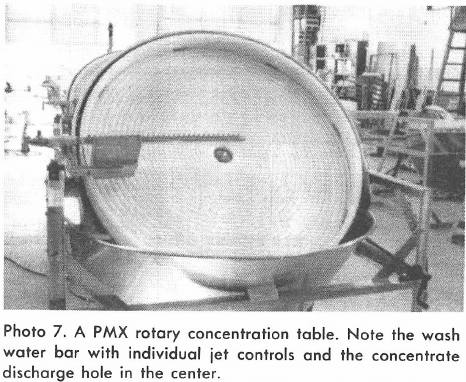

An interesting variation of the spiral concentrator is the rotary table. This device is available from a variety of manufacturers under many trade names. Basically, the rotary table consists of a flat, circular plate in which a spiral pattern has been molded or cut. It is usually mounted on a frame with a wash water bar running laterally from the one side to the center. When operating, the unit is tilted upward and the table is rotated clockwise. Material is fed in on the left side. Tailings are washed over the bottom lip, while concentrates are carried towards the middle and flow through the discharge hole (Photo 7).

An interesting variation of the spiral concentrator is the rotary table. This device is available from a variety of manufacturers under many trade names. Basically, the rotary table consists of a flat, circular plate in which a spiral pattern has been molded or cut. It is usually mounted on a frame with a wash water bar running laterally from the one side to the center. When operating, the unit is tilted upward and the table is rotated clockwise. Material is fed in on the left side. Tailings are washed over the bottom lip, while concentrates are carried towards the middle and flow through the discharge hole (Photo 7).

The rotary table concentrates material through a combination of gravity separation and fluid forces. As the table rotates, wash water forces light material downward over the spirals. The centrifugal force generated by rotation forces heavier material into the troughs of the spirals

where the washing action of the water is minimal. In some machines, the spiral pattern varies in height much like the tapered riffles on shaking tables. The higher initial spirals allow the heavy material to settle. The shortening of the spirals towards the center of the table allows wash water to clean the concentrate before discharge. The wash water flow determines the density of the final concentrate. A strong flow will wash away most of the lighter material, producing a heavier concentrate, while a milder flow will remove less light material, reducing the density of the final concentrate. For more control in concentration, Precious Metals Extraction (PMX) puts individual controls for each jet of water on the wash water bar. These controls allow the operator to adjust individual wash water jets for maximum effect.

In a test of a PMX table, an independent laboratory (Golden State Minerals, Inc., Auburn, California) separately processed 3 pounds of black sands screened to minus 20 mesh (.85 mm) and 200 pounds of gravel screened to -¼ inch. These samples were amalgamated and were observed to contain mercury droplets smaller than 500 mesh (30 microns). Results show the PMX rotary table recovered 99.91% of the mercury contained in the black sands and 99.95% of the mercury contained in the gravel. Microscopic examination of the tailings revealed a trace of -500 mesh (30 microns) mercury (Cassell, 1981). Rotary tables are very efficient cleaners. Their low capacity limits their use as roughers.