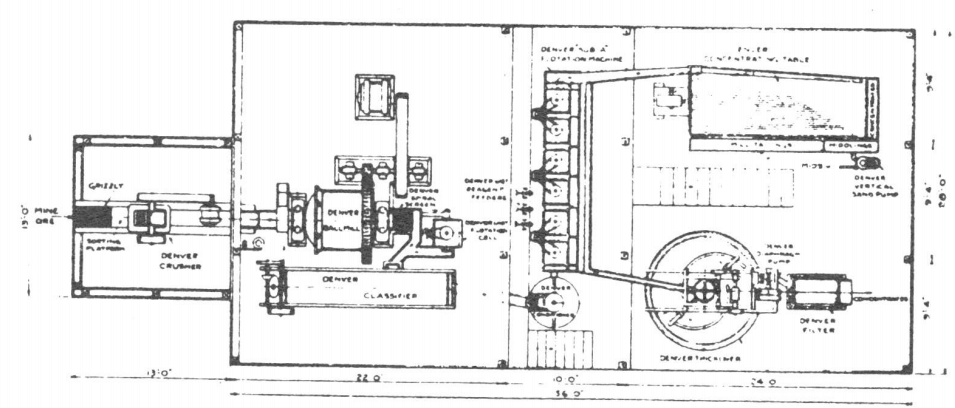

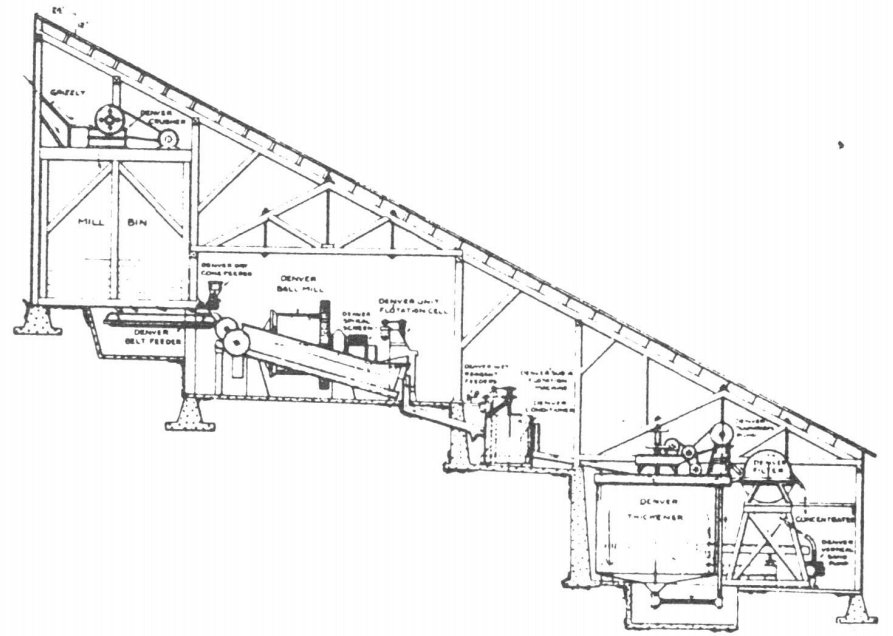

The 50 to 75 Ton per Day process plant is the most practical size for the average milling plant. The 9″ x 16″ Jaw Crusher (forced feed) produces enough crushed ore for the ball mill on one eight hour shift to run the balance of the mill for twenty-four hours. Oversize primary crushers are recommended for most economical results. Note the flexibility of the flowsheet and the gravity flow through the mill which eliminates elevators, conveyors and pumps (except for middling products).

Advantages include motor “V” Rope drives and ample room. On gold ores a Selective Mineral Jig in the grinding circuit may be advisable.

The simplicity of the flowsheet makes it easy to operate and eliminates difficulties.

For a process plant under 50 TPD

All primary process equipment total around 30000 Kilos OR 65000 lbs in weight.

| Process Equipment List | Motor HP |

| 10″ x 16″ Jaw Crusher | 12 |

| 15″ x 6′ Belt Ore Feeder | 0.5 |

| 5′ x 5′ Ball Mill (Steel Head) | 40 |

| No. 100 Unit Flotation Cell | 1.5 |

| Spiral Screen | |

| 30″ Cross-Flow Classifier | 2 |

| 5′ x 5′ Conditioner and Tank | 1.5 |

| 4 Cell No. 15 “Sub-A” | 4 |

| Simple Reagent Feeder | 0.25 |

| Triplex Wet Reagent Feeder | 0.25 |

| No. 6 Concentrating Shaking Table | 1.5 |

| 1.5″ Vertical Sand Pump | 2 |

| 10′ x 8′ Thickener and Tank | 1 |

| 2″ Diaphragm Pump | 0.5 |

| 4′ x 2 disc Disc Filter | 1 |

| Vacuum Equipment for Filter | 4 |

| Total | 75 HP |

https://911metallurgist.com/process-plant-design-equipment

https://911metallurgist.com/mobile-ore-processing-beneficiation-plant