The Ore and Water Skip is furnished in a few standard sizes, but any size or style can be supplied. When these skips are used for handling water an automatic valve is supplied which is placed in the bottom.

Two styles are made as to attachment of the wheels and axles. In style “A” the axles are riveted to the sides, while in style “B” the axles extend across beneath the car. The illustration above shows the style “B” skip without a top or upper side. Ore and Water Skips are also available with riveted steel tops. The table below includes only data on units having steel tops but additional information on units without tops will gladly be furnished upon request.

When ordering, specify whether for ore or water, capacity desired, weight of one cubic foot of material to be handled, track gauge, angle of incline of shaft, and any limiting dimensions.

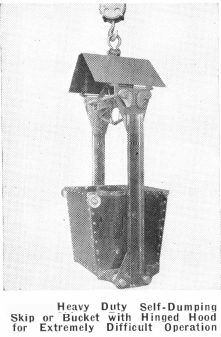

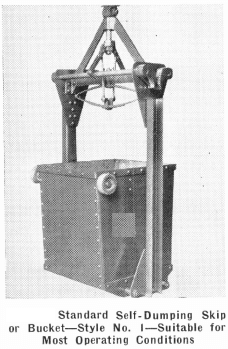

Self-Dumping Skip or Bucket

Self-Dumping Skip or Bucket is heavily built to withstand the wear and tear of loading, rapid hoisting, and strains incident to dumping.

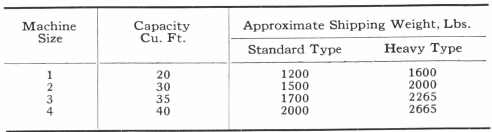

Two styles are available. Style No. 1 is the standard type and Style No. 2 is the heavy duty type with hinged hood. The standard type will satisfy most operating conditions, but for extremely difficult operating conditions and heavy loading the heavy duty type is preferable.

The standard type ore bucket or skip is of the self-dumping type, constructed of 3/16″ boiler plate, and heavily reinforced with iron bands. Guides are made of heavy channels, flared on the ends, and solidly riveted to the carrier and headframe. Headframe yoke and safety dogs are of carbon cast steel. The lifting eyebolt is made of forged steel while the safety mechanism is the widely used, extra heavy duty type. Safety dogs are of ample size and so shaped to make it impossible for them to turn over and not grip the guides, as they are operated by a heavy elliptical spring.

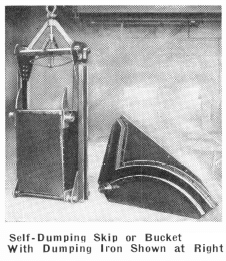

Dumping rails can be supplied for either the Style No. 1 or the Style No. 2 Self-Dumping Skip or Bucket. These dumping rails are made of rolled steel angles. They are welded to heavy sideplates and so designed to permit the skip or bucket to hang inverted on the frame after dumping has occurred. Two guide horns, riveted to the sides of the skip or bucket, guide it into the dumping rail which in turn reverses the unit while it is being lowered. Approximate shipping weight of dumping rails is three hundred pounds per pair.

The importance of reliability and experience in building the type of equipment used in the mining and milling industry cannot be over-emphasized. Requirements are very exacting. It is not only the cost of the equipment and the realization that the remote places where this equipment is often used makes replacements and repairs very difficult to obtain, but also the importance of providing maximum safety protection for the human lives at stake.

NOTE: Due to the large number of variable dimensions, the Self-Dumping Skip or Bucket is made only on order and in accordance with specific requirements.