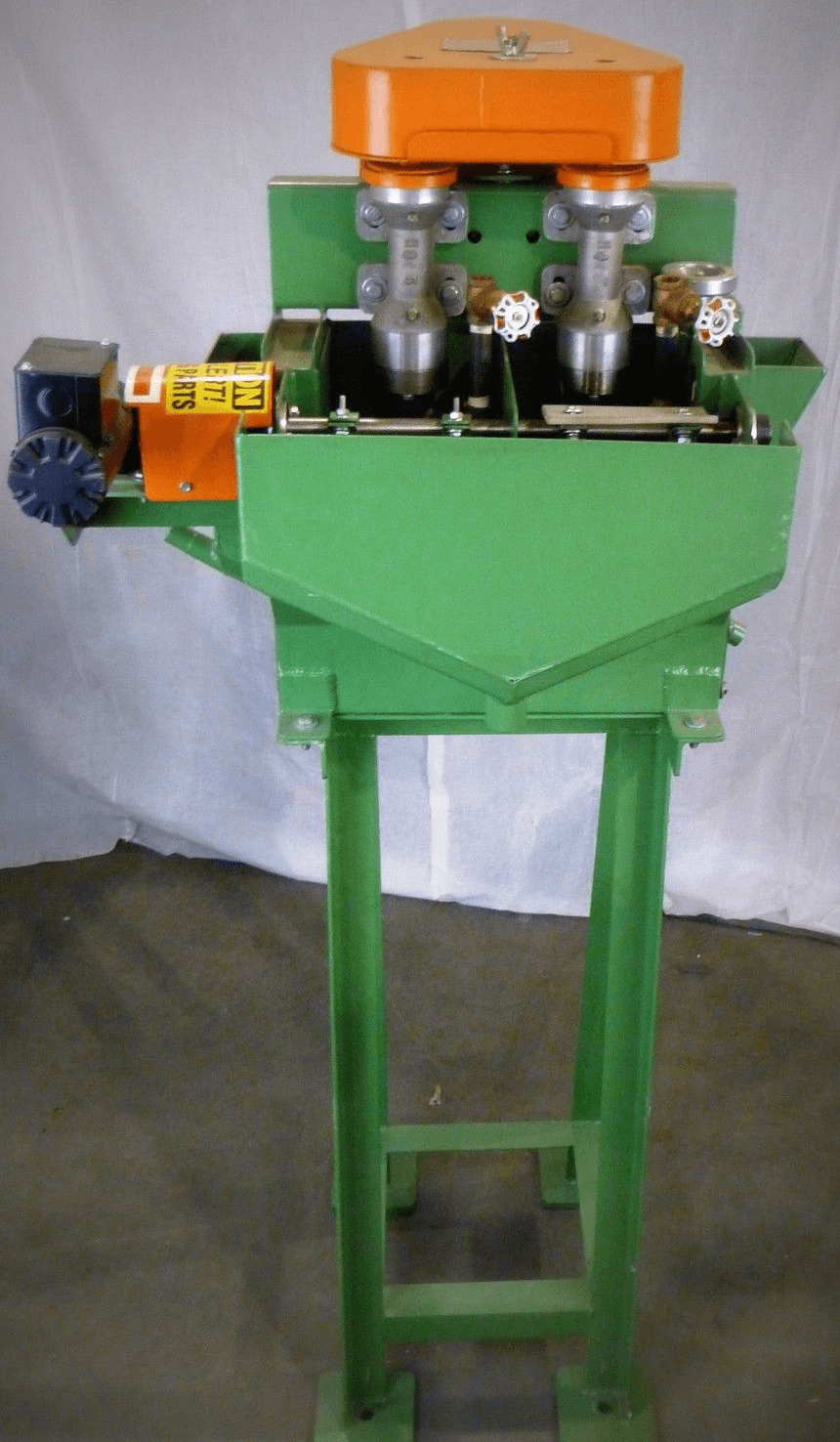

For Sale: QPEC No. 5 Flotation Machine (Small 0.3 cubic feet per cell), “cell to cell” construction as generally described in brochure QPEC F-001. All wetted steel is mild steel. Includes bank cell design with tank with adjustable height weir between the cells and weir box with adjustable height level control and adjustable sand relief at end cell only.

Drive to consist of dual cell 1 hp, 3,60,575 volt (other voltages available) TEFC motors with variable pitch motor sheaves, v-belt drives and OSHA type drive guards.

Mechanisms to consist of aluminum spindle bearing housing with grease lubricated ball bearings, mild steel standpipe with grease seal with brass air control valve, polyurethane impeller and diffuser.

Unit includes froth launders (configuration to come), froth paddles and a FHP 1,60,110/220 volt gearmotor drive.

All non-wetted steel to be sandblasted and epoxy coated.

Sub-A Design … These cells do not require blower added air as they are self-aspirating.

Sub-A Design … These cells do not require blower added air as they are self-aspirating.

- 2-cell QPEC No. 5 Flotation Machine

- (0.3 cubic feet per small cell)

- (0.6 liters per Machine)(i.e. both cells)

- Open Flow Design – Includes tank partition between cells in each machine.

- All machine end cells include a manually adjustable height overflow weir and adjustable sand relief gate.

- Mild steel tanks with mechanism support headers.

- All non-wetted steel has been sandblasted and epoxy coated.

- Heavy Duty Support Stands

- Drives to consist of

- Dual Cell ¾ hp, 230/460 volt TEFC motors

- Variable pitch motor sheaves

- V-belt drives

- OSHA type drive guards.

- Mechanisms include:

- Standpipe with air control valve

- Polyurethane impeller

- Polyurethane diffuser

- Mild steel shaft.

- Aluminium spindle bearing housing

- Heavy duty ball bearings

- Dust cap

- Grease seal.

- Each bank of cells (machine) to include:

- Froth paddle drive with 110/220 volt gear-motor

- Adjustable torque clutch

- Polypropylene paddles

- Mild steel shaft and ball bearings.

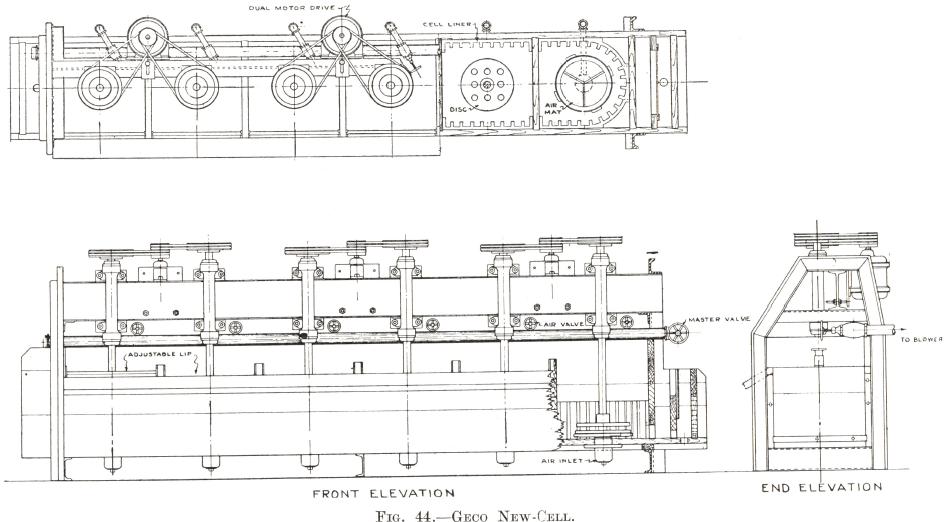

Flotation and Flotation Engineering are playing an increasingly important role, not only in metallic and non-metallic ore processing but in industrial and chemical processing applications as well. Representative uses include separation of ore, de-inking waste paper, recovery of oils, greases and metal filings from manufacturing plants, purifying paint pigments, recovery of naphthalene from by-product wastes, reclamation of silver salts from photographic developing chemicals and a wide variety of chemical processes. Also used for water purification.

Design incorporates a universal tank with three types of mechanisms: (A) “Cell-to-cell”; (B) “Free-flow”; and (C) Type “M”. Sizes from 16″ x 16″ to 72″ x 72″. Flexibility and simplicity are distinctive features of “SUB-A” machines.