Since time immemorial, Mother Nature has been transporting slurries with both air and water serving as the carrier medium. Consider for example the formation of the continental shelves off our coast lines which are being formed by rivers emptying erroded land surface and depositing it into bays and gulfs. As the erosion processes take place, the fines are suspended in water which flows in streams and rivers and deposits where the velocity of the flow reduces sufficiently to allow the fines to settle out. The same process in some crude form is provided when one hoses his driveway or patio and moves dirt so as to provide a cleaning action.

The movement of liquids in pipelines necessarily occasions the use of pumps for the purpose. Those of us who have had some rub with the petroleum industry are familiar with the transport of solids through mud pumps and cementing and fracturing pumps where the movement of slurries is an everyday matter. In the drilling of an oil well the circulating fluid utilized to remove chips which are cut by a drill bit from holes drilled deep in the earth is called drilling mud. This substance contrary to what the name might imply is usually a fairly sophisticated material designed to develop certain characteristics which are desirable in the drilling process.

Over the years mud pumps have been improved so that rather long life can be obtained from liquid end parts subject to the attritional effects of the abrasive-laden fluid. It is with this background that reciprocating type slurry pumps have been developed.

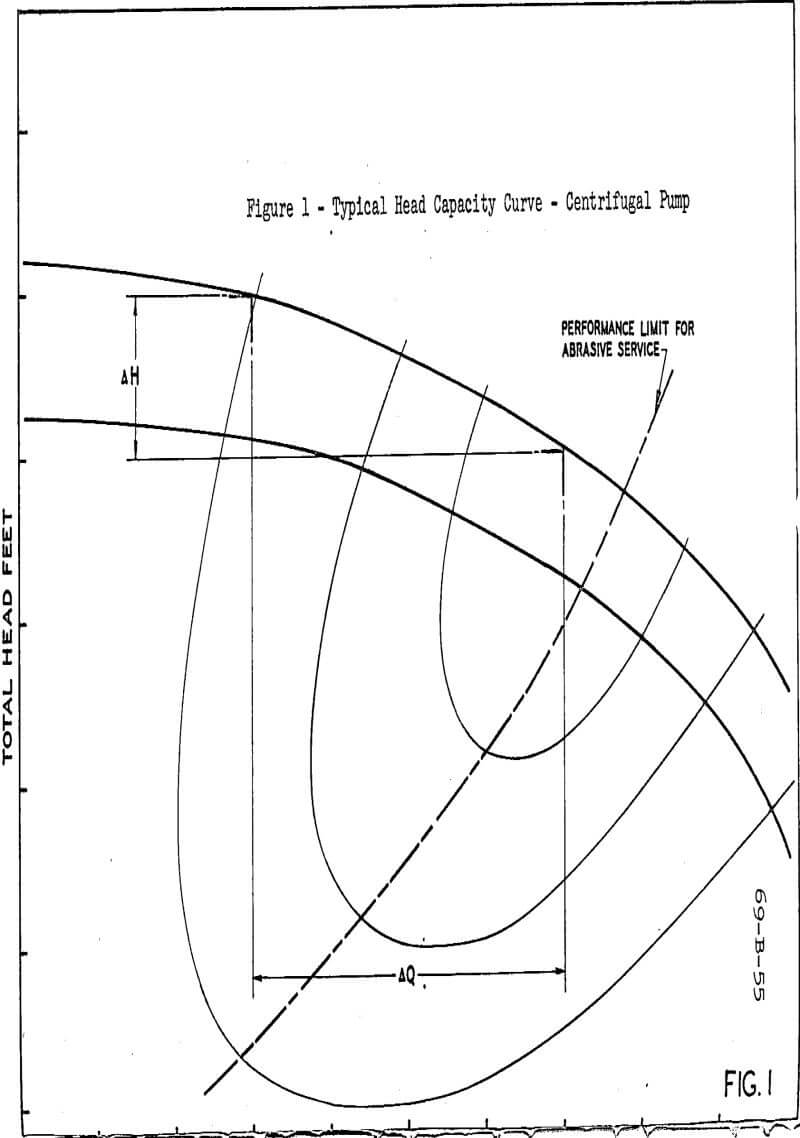

Centrifugal pumps have also been used to transport solids. These have been used where low heads are required, typically up to 200 feet or so, for short hauls. One may recall that a centrifugal pump is a hydrokinetic device where the increase of velocity in a fluid stream is converted to head, and to accomplish high heads a large change in velocity is necessary. Abrasive laden fluids have a deteriorating effect on impellers and casings as a result of the erosion caused by the fluid and the suspended particles. Therefore, these pumps can only be used where the internal velocity of flow is relatively low.

Reciprocating pumps have the desirable characteristic of maintaining a high volumetric efficiency at any desired flow rate. This allows a greater flexibility in system design. Because of the positive displacement and high efficiency features these pumps can be used for metering station through-put. Reciprocating slurry pumps are so designed to have easily and quickly replaced liquid end parts which are subject to the deteriorating effects of slurries. Other pump designs usually require complete dismantling and overhaul.

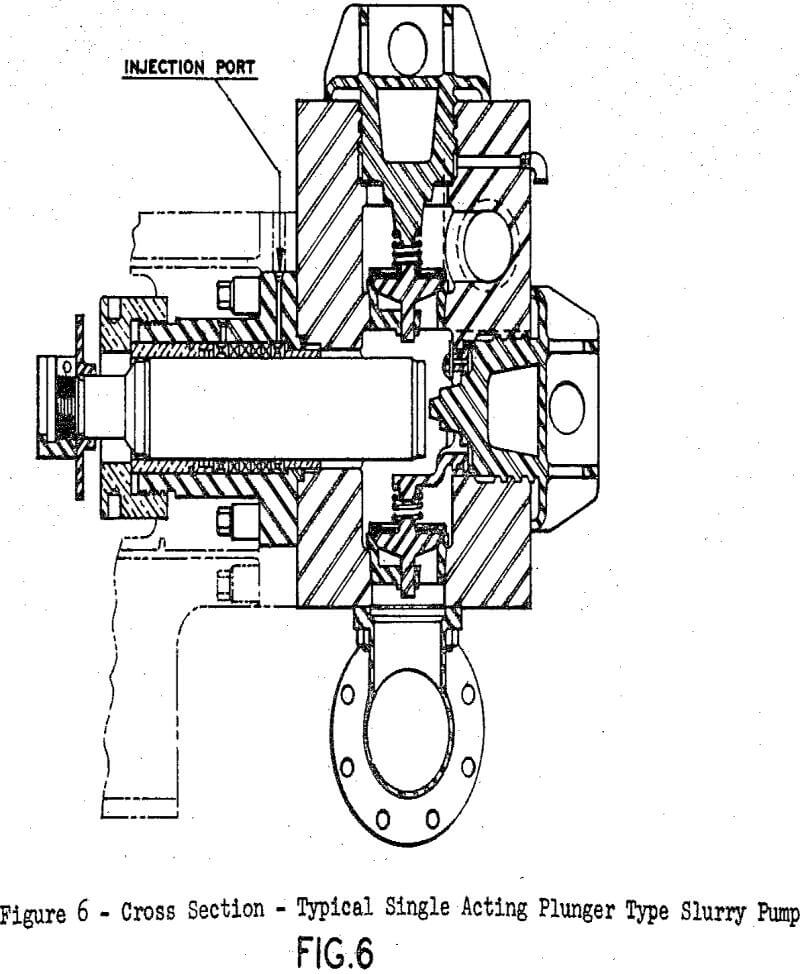

Two basic approaches are utilized in the handling of slurries with reciprocating pumps. In the one case, the direct action of the displacement member in the liquid end is affected directly by the abrasive liquid. In the other case, a clean liquid barrier is provided between the abrasive liquid and the sealing element. In plunger pumps a liquid seal is created by an injection of water, or other appropriate liquid ahead of the plunger packing in such a way that the packing contacts no abrasive liquid.

The abrasivity of a slurry is theoretically a function of the hardness and shape (sharpness) of the particles. However, there are two effects of abrasivity, first, the action on metal or elastomer caused by erosion resulting from velocity of flow and, secondly, the reaction on metal of elastomer caused by mechanical abrasion, or rubbing together. In the first instance, particle size and density are additional characteristics that must be considered. In the second case, density probably has no affect on wear rate. Our experience has been such that mechanical abrasion as opposed to erosion is unpredictable and little knowledge is available at the present time. Considerable work has been done in this area and as a result we have developed a standard method of measuring the abrasivity of slurries. A separate paper on this subject is being prepared for presentation in the near future.

We have done a great deal of research regarding the performance of pumps using slurry type valves in a wide range of suction conditions. For example, it has been found that the weight of the valve is not as critical as one might expect because a valve is not “slammed” shut. Its motion follows the sinusoidal displacement pattern of the piston (or plunger) thus allowing for a gentle opening and closing. However, with inadequate suction conditions violent behavior of a suction valve does occur with consequent destructive effects.

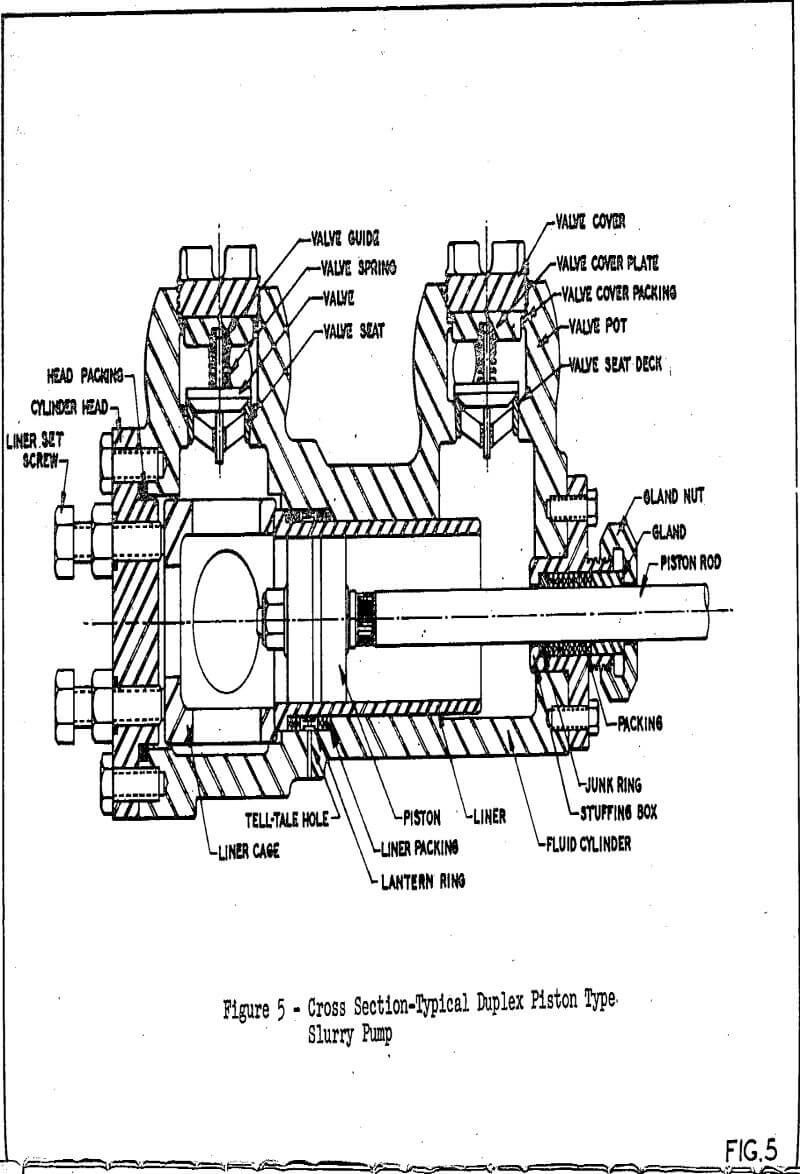

In a piston pump the piston which displaces the fluid runs in a renewable metal cylinder, or liner. The piston rod runs through its packing and presents a second point of sealing and wear. In the case of a single acting pump, the plunger with its packing presents the only comparable point of wear.