Table of Contents

The purpose of a vacuum filter is “Slurry Filtering” and therefore to remove more of the water from the concentrate, this “Concentrate Filtration” is accomplished by using a vacuum. Again for your understanding of the method you will have to know something about the design of a filtering system and of course the filter itself. There is always something being filtered in the mining industry. This means many different types of filters. They range from a simple folded paper in a Pyrex funnel that is used in laboratory work to the large production filters that are capable of filtering all of the daily mill run. The systems used may be a pump to force the solution through the filter like the filter presses which are used in the techniques of gold recovery, or a container pressurized by air to force the liquid out of the solids. The ones that we are interested in, and are used the most in production, are the filters that use vacuum as their drying agent.

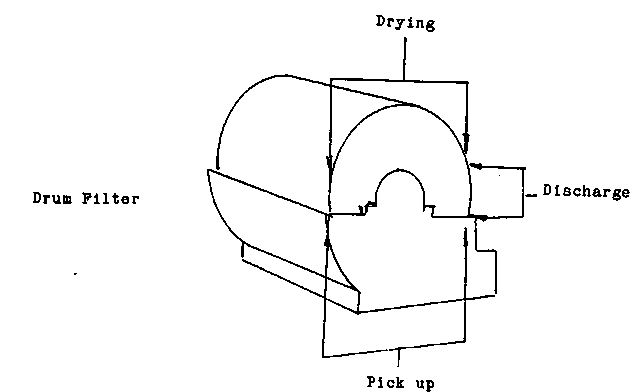

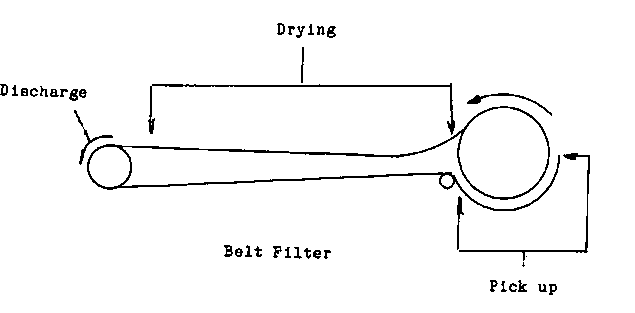

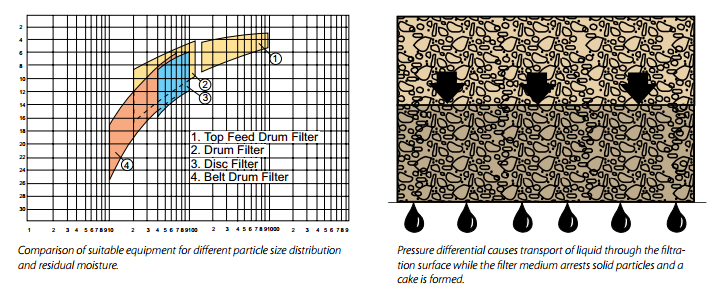

There are three main designs of these filters a DISK FILTER, DRUM FILTER, and BELT FILTER. Although the system that each uses is very similar and knowing one makes the others easy to figure out, the disk filter has operational qualities that make it the one most prominently used. For this reason we will stay with the disk filter and use it as our model.

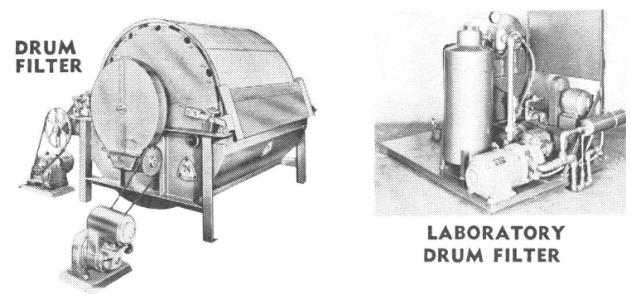

DRUM FILTERS

For continuous, dependable dewatering or for washing leaching solution from dewatered solids. Sizes from 18″ through 6′ diameter. Repulpers also available.

PAN FILTERS

A simple low cost filter with high filtering capacity per square foot of area due to combined gravity and vacuum method of filtration. Simplex or duplex filters available. Duplex units preferred because two products can be filtered simultaneously in batch process, or continuous filtration can be employed on a single product by alternately filling and discharging the pans. Acid-proof pan filters available.

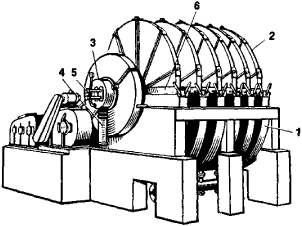

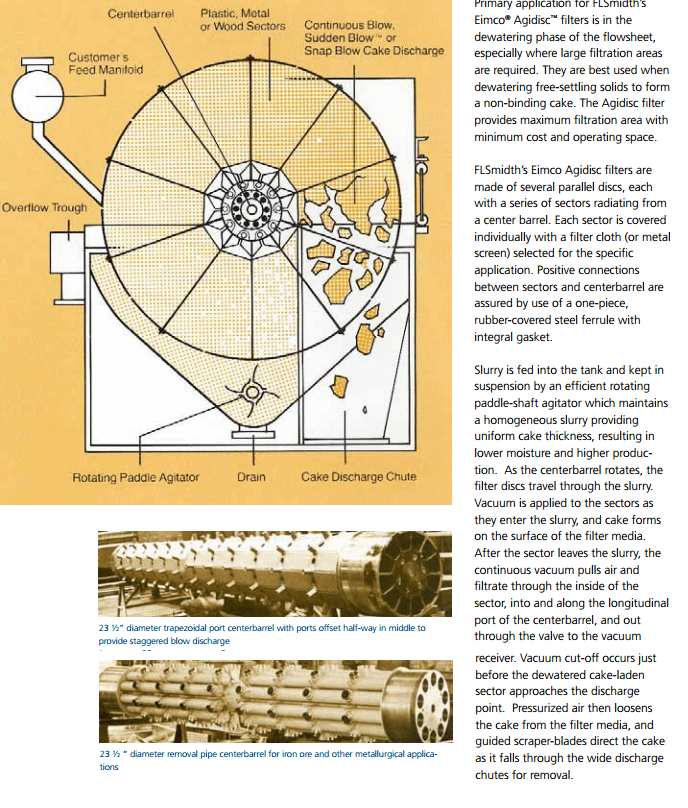

DISC FILTERS

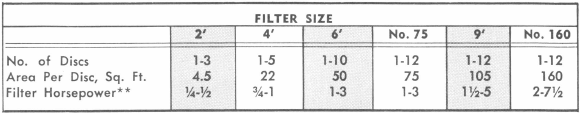

Provides large filter area in limited space. Patented agitator unit keps solids in suspension, assures thick, even filter cake. Ideal for continuous dewatering of pulps which form relatively thick cakes and for filtering two or more products in single unit. Choice of filter media. Sizes from 2′ diameter x 1 disc to 10′-9″ diameter x 12 discs.