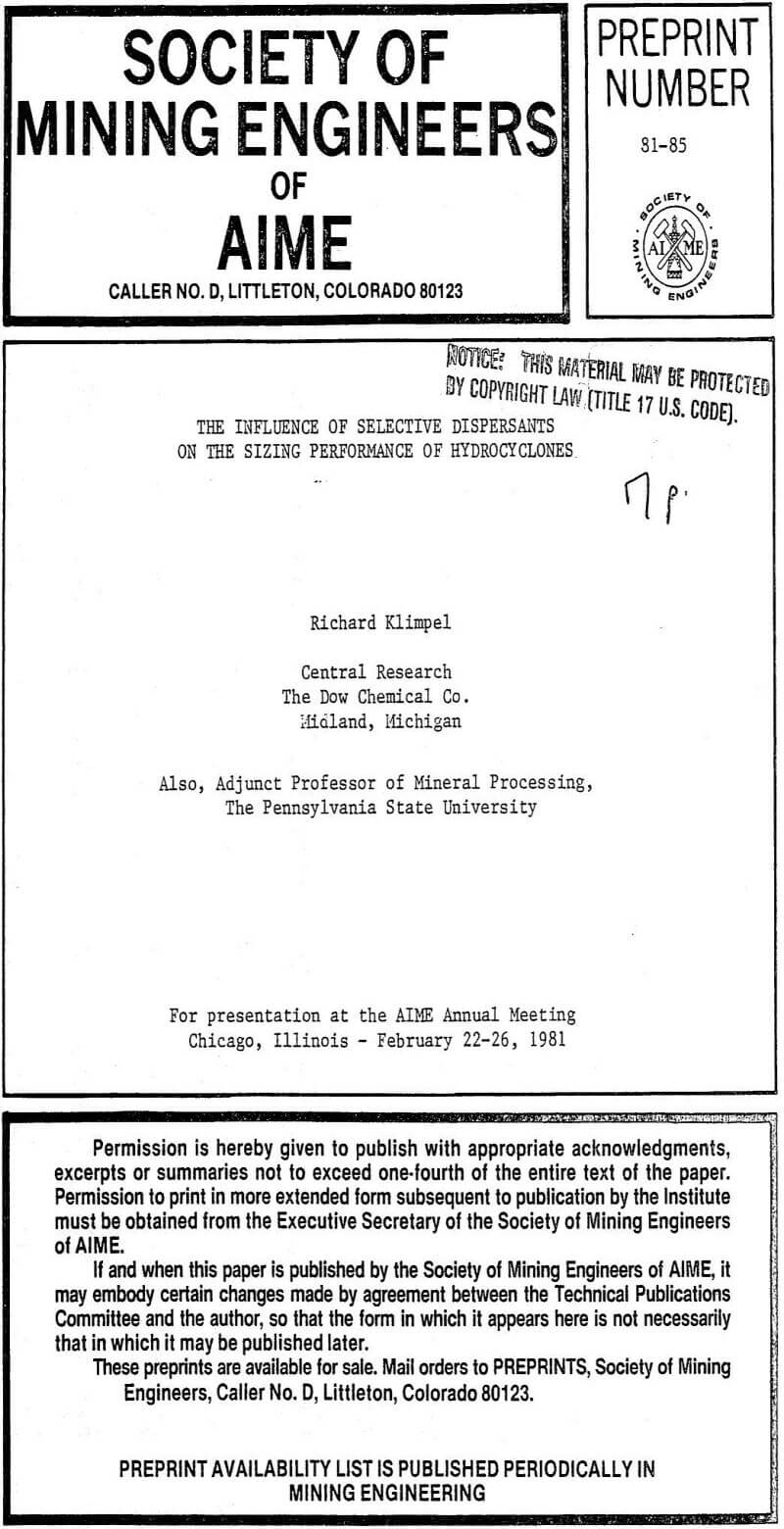

A series of tests on a 24 inch hydrocyclone operating on a copper ore slurry were run. The ore was selected so as to be reasonably homogeneous with regard to the density of components so that particle size differences dominate the classifier action. The primary variables were % solids (and associated viscosity readings), the feed rate of slurry, and the dosage of the grinding aid, XFS-4272. Every precaution possible was taken to ensure steady flow and consistent feed particle size make-up to the hydrocyclone within each test (and also between tests). Composite sizing samples of all three streams pi, ti, and qi and related water contents were taken for each test. The results of each test condition were then summarized by a set of parameters: “a”, d50, S.I. and water fraction to coarse stream, w.

Table I gives a typical set of results for two test sequences.

The conclusions that appear valid from the results of Table I Include:

- Increasing slurry density at the three feed rates studied without chemical causes a decrease in by-pass fraction “a” and a decrease in d50 value (both observations well known from industrial practice) and a decrease in Sharpness Index value. The use of chemical has some effect on increasing the by-pass fraction “a”. At the higher slurry density, several positive influences are exerted by the chemical with increases being observed in both the d50 and S.I. values. As feed rate is increased at the higher slurry density, the influence of the chemical is increasingly obvious. At the lower slurry density, the effect of the chemical is more marginal at all feed rates as might be expected.

- At the higher slurry density, in both the normal cyclone operation (spray) and unstable operation (rope), the use of the chemical increases the d50, S.I. and by-pass “a” values. With regard to chemical dosage, the major gain in performance is achieved with the 150 gram/ton of solids dosage with the 300 gram dosage giving improvement but at a reduced rate. It is interesting to note that at the higher % solids, the use of a selective dispersant is apparently improving some inefficiencies of the cyclone operation (e.g. increasing d50 and S.I. values) while clearly worsening another type of efficiency (the increase in particle by-pass “a”).

In order to better understand the practical implications in a closed grinding circuit of the possible cyclone efficiency trade-off indicated above, computer simulations of a complete grinding circuit can be performed. Such a simulation approach is being used more frequently in recent years for circuit evaluation by many workers in this area and is outlined in detail by Lynch (1977) and by Austin, Klimpel, and Luckie (1980). Simulation of a closed grinding circuit includes a mathematical representation of the cyclone (hence the “a”, d50, and S.I. values) and appropriate grinding mill parameters. Once developed for a given circuit, selected “changes” in operation can be simulated under various assumptions.

The influence on circuit production rate and product size as a function of changes in hydrocyclone operation can thus be examined by changing appropriate values of “a”, d50, and S.I. At the present time, this author and co-workers are performing two such detailed simulations on existing plants using XFS-4272. Very preliminary results of this work show that the potentially negative influence of the possible increase in “a” with chemical is generally dominated in industrial circuits by the positive influences of the chemical. These positive influences are the increasing of the S.I. value and the allowing for higher cyclone feed rates and/or higher slurry densities without the corresponding decrease in d50, that usually occurs without chemical. Such positive influences can lead to higher throughput rates of the circuit (with obvious economic implications) and steeper product size distributions [which can improve flotation response, e.g. see Klimpel and Hansen (1981)]. Further work in this area of simulating circuit performance with and without XFS-4272 will be published in the near future.

It suffices to say at this point that the industrial use of XFS-4272 as a grinding aid in both open and closed circuit operations is well documented with increases in throughput of greater than 10% at the same size of product being relatively common. With such data, it is highly unlikely in practice that the influence of viscosity control chemicals on hydrocycloning is negative. Based on the data collected in this study and the over-all circuit performance data indicated above, the more likely question is: Just how positive are the effects of viscosity control chemicals on hydrocycloning in any given industrial application?