Table of Contents

There are no set rules for determining whether the secondary stage should consist of one single crusher, or of two or more machines operating in parallel. The decision must be made upon the merits of each problem. If the required receiving opening necessitates the selection of a crusher whose capacity equals or exceeds that of the primary crusher there is no object in going to a two-stage arrangement. Frequently this will be the case where a primary jaw crusher is to be followed by a gyratory machine. On the other hand, if the primary is a large gyratory, and the full output of this crusher is to gauge the. output of the plant, it will be necessary to install a, battery of two or more gyratories for the secondary reduction. The number and size of these will depend upon the size of the primary, its setting, the type of secondary to be used, and its setting. It is desirable that the multiple set-up be selected in even numbers, rather than odd; that is, either two or four units, rather than three. The difficulties in achieving an equitable distribution of feed into three units has been amply demonstrated in a number of plants.

From the standpoint of flexibility there is something to be said in favor of the multiple secondary stage, although the advantages are not so pronounced here as they are in the reduction crushing stages, unless of course the secondary stage is likewise a finishing stage. When the secondary stage is simply an open-circuit step in the over-all reduction flowline, the advantage of the multiple unit rests in the fact that single machines may be taken out of service for repairs without total interruption of the plant operation, although the feed rate must be reduced unless enough excess capacity is installed in this stage to permit cutting one machine out of service without affecting the average flow-rate through the plant. It is questionable if this much excess capacity is ever justified in a two-unit secondary stage; on the other hand, if the stage is to comprise four or more units, it is sound engineering to provide such extra capacity. The answer must in any case he predicated upon the relative importance of uninterrupted full-capacity operation.

Reduction Stages

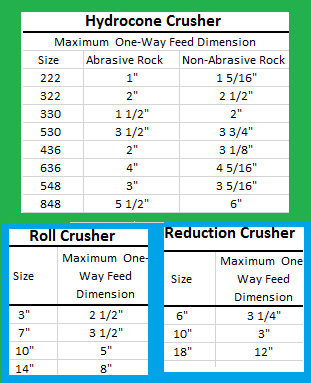

Much of the foregoing discussion of secondary crushing stages will apply equally well to any succeeding stage, especially so if the stage is to run in open circuit. The cardinal factors of capacity, feed size and product size must he checked in very much the same fashion, keeping in mind the probable difference in types of crushers to be used. Usually, when we arrive at the third stage in a crushing plant, we are dealing with reduction or fine-reduction crushers where the feed size, as established by the open-side setting of the preceding stage, must be checked against the maximum one-way dimension of rock that the reduction crusher will nip.  This comparison is usually all that is required to assure an adequate receiving opening, but it should be kept in mind that this maximum nip-dimension is not the full radial receiving- opening of the reduction-type crusher. In our own lines of reduction and fine-reduction crushers this differential in full, and effective, receiving opening applies to the Superior reduction crusher, the Newhouse crusher (with full-curve, non-choking concaves), and the Hydrocone crusher, To assist in the selection of machines of these types the following table has been prepared to show the maximum one-way dimension of rock that each machine will nip. These dimensions are for minimum crusher settings. In the case of the first generation crushers they will increase by whatever amount the proposed setting exceeds the minimum. For both of these machines the figures apply to full-curve, non-choking concaves.

This comparison is usually all that is required to assure an adequate receiving opening, but it should be kept in mind that this maximum nip-dimension is not the full radial receiving- opening of the reduction-type crusher. In our own lines of reduction and fine-reduction crushers this differential in full, and effective, receiving opening applies to the Superior reduction crusher, the Newhouse crusher (with full-curve, non-choking concaves), and the Hydrocone crusher, To assist in the selection of machines of these types the following table has been prepared to show the maximum one-way dimension of rock that each machine will nip. These dimensions are for minimum crusher settings. In the case of the first generation crushers they will increase by whatever amount the proposed setting exceeds the minimum. For both of these machines the figures apply to full-curve, non-choking concaves.

Two sets of maximum-nip dimensions are listed for the Hydrocone crushers; one for abrasive and one for non-abrasive material. An examination of the cross section through the crushing chamber of any flared-top shell crusher will make it clear that the effective receiving opening decreases as the head is raised. When crushing abrasive material, mantle and concave wear is relatively rapid as compared to the wear when crushing non-abrasive rock; furthermore, the wear is, comparatively, more rapid in the lower part of the crushing chamber, in contrast to the more even wear on non-abrasives. Hence, as the head is brought to its top position in adjusting for this wear, the effective receiving opening will be somewhat less for the crusher operating on abrasive rock. The effective openings listed are for the top position of the head; at lower positions the opening will be slightly more.

In making our check of receiving opening VS discharge opening of the preceding stage, we should observe the same precaution suggested for the primary-secondary combination: the discharge setting against which we check the nip-dimension of our crusher should be the maximum opening at which we have reason to believe the preceding crusher will ever be operated. Usually secondary crushers can be, and are, maintained more closely to the established setting than are the larger primary machines, some of which are without means of adjustment other than resetting of concaves or replacement of mantles; nevertheless it is extremely difficult in actual practice to maintain crusher settings within narrow limits with a few exceptions, and some margin should be allowed for this.

Size of Feed

If the secondary stage is to consist of one or more standard type gyratory crushers, with or without non-choking concaves, the radial receiving opening should be not less than 2.5 to 3 times the open-side discharge setting of the primary crusher. The larger ratio should be observed for primary jaw crushers, because of the slabbing propensities of this type. Thus, if the primary is one of the 84″ class of jaw crushers set at 10 in., the secondary machine should be not less than a 30″ gyratory with straight concaves, or a 36″ size if fitted with non-choking concaves (32″ receiving opening). A primary gyratory, set at 6″ may be followed by one or more 16″ crushers with straight concaves, or by the 20″ size if fitted with non-choking concaves (16.5″ receiving opening).

When the secondary stage is to consist of gyratory crushers of the reduction type, the ratio may be somewhat lower than those for the standard machines because, for a comparable radial receiving opening, these reduction types have larger diameter crushing chambers and, hence, longer openings (as measured parallel to the spider arms. Usually from 2 to 2.5 times the primary crusher setting will be satisfactory. These cylindrical-top-shell crushers, when fitted with reversible, full-curve non-choking concaves, have effective receiving openings which are considerably less than the radial distance from top-of-head to top-of-concaves. This effective receiving opening must be at least as large as the maximum open-side setting at which the primary crusher will ever be operated (that is, when mantle and concaves or jaw plates are worn thin).

Fine-reduction crushers, such as the Hydrocone, also have effective receiving openings which are smaller than their full rated openings; therefore one must observe the same precaution in selecting sizes of these machines as with the reduction types mentioned in the preceding paragraph.

In selecting crushers of the roll type to follow a preceding stage the maximum permissible nip-dimension must be not less than the maximum discharge setting of such preceding stage; and the length of roll face should be at least 4 to 5 times this setting.

Hammermills should have a minimum throat opening not less than double the setting of a preceding stage of either gyratory or jaw crusher; and the lateral throat opening should be from 4 to 5 times such setting.

Although their characteristics are not particularly favorable for secondary or reduction crushing service, jaw crushers are sometimes so used, for example, in portable and semi-portable plants and in small mining installations. Usually the machines are the single-toggle or cam-actuated types, with receiving openings whose lateral dimension is at least double the dimension from top-to-top of the jaw plates. The lateral opening should be at least twice the discharge setting of the preceding stage, and when non-choking jaw plates are used the effective nip opening must be checked against this discharge setting, just as is done for the gyratory types.

Product Size

Regardless of the number of stages of reduction in the plant, the primary crusher, at least in those plants designed to handle shovel-loaded rock, is usually set at or near the minimum safe discharge setting for which it is designed, although as we have stated, this setting may not be strictly maintained over a long period of time. This practice of utilizing the full permissible reduction-ratio of the primary crusher is quite sound from several standpoints. The primary crusher represents a substantial investment, and the user is justified in his desire to obtain from it all the reductiop* of which it is capable. Furthermore, the machine is likely to have some excess capacity as compared to the succeeding units in the plant, even at its minimum setting. When such is the case there is nothing to be gained by operating it at a coarser setting. Thirdly, if the primary is a medium or large size machine, its minimum setting will be wide enough to obviate any excessive creation of fines by attrition; in any event the difference in percentage of fines produced at the minimum setting, as compared to any coarser setting, will not seriously affect the percentage of fines in the finished plant product. Unless the material is very hard and tough, or contains a viscid admixture which makes it difficult to get through the crusher, everything is in favor of working the primary at its maximum safe ratio-of-reduction.

The arguments in the preceding paragraph do not always hold good for the secondary stage. Here the discharge settings are much finer, and the ratio-of-reduction begins to have a significant influence upon the percentage of fines that will show up in the plant product. Therefore, where minimum fines are desired, the amount of work done in the secondary stage should be held within conservative limits. The characteristics of non-choking are to be minimized, unless the setting of the secondary stage is to be quite coarse.

For the combination of large jaw crusher followed by a gyratory of the 30 or 36″ size, there is no particular reason why the maximum reduction-ratio cannot be utilized through both stages, especially if interstage scalping is employed. These secondaries are quite large; in fact such crushers serve as primaries in medium size crushing plants; and their minimum settings are wide enough to permit operating them in the manner suggested without excessive fines production.

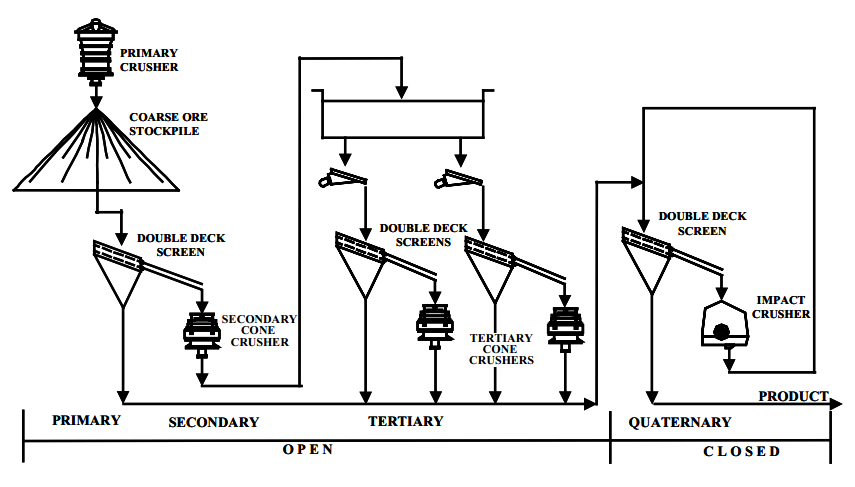

Stage-Crushing VS Closed-Circuit Crushing

This open-circuit, stage-crushing system is an excellent arrangement for the commercial crushing plant, because it tends to minimize production of fines, especially so if the ratio of reduction, per stage, is held within moderate limits. The system can be carried out to a point where relatively little tonnage need be handled in closed-circuit, as has been exemplified in a number of plants during recent years. As an example: a plant is running, let us say, with a final, close-circuited stage that is taking an original feed of about 100 tons per hour, with a circulating load of about 25 tons/hour through this stage. If a small “clean-up” crusher is installed to handle the 25 tons oversize; this machine being set somewhat ’finer, of course, than the larger machine; the circulating load through this smaller crusher can generally be held within 5 tons per hour, and the feed rate to the former final-stage can be increased by the amount of the circulating load which has been removed from it. This practice of adding “clean-up” crushers to an existing flow-line is becoming increasingly popular, particularly where the demand for smaller sizes of product has been throwing a heavy strain on existing equipment.

Open-circuit, stage-crushing is equally well adapted to the preparation of feed for grinding mills. For such service the reduction per stage need not be limited with a view to minimizing fines; otherwise, the design factors are much the same as for the aggregates plant.

Nothing that we have said here should be construed as antagonistic to the closed-circuit, crushing-stage. which is a very necessary adjunct to most minerals-reduction plants. What we are trying to convey is the fact that material which has been through a pressure-type crusher once can be processed more efficiently, for further reduction, in another crusher, or crushers, with smaller discharge setting; and, that circulating loads should be held to a minimum by carrying the stage-crushing system through to its logical limit.

| Cited Patent | Filing date | Publication date | Applicant | Title |

|---|---|---|---|---|

| US525410 * | Nov 9, 1893 | Sep 4, 1894 | gates | |

| US525443 * | Sep 4, 1894 | carman | ||

| US532329 * | Nov 14, 1892 | Jan 8, 1895 | The Gates Iron Works | Stone-breaker |

| US1047859 * | Dec 7, 1911 | Dec 17, 1912 | Traylor Engineering And Mfg Co | Gyratory crusher. |

| US1336015 * | May 2, 1919 | Apr 6, 1920 | Traylor Engineering & M F G Co | Gyratory crusher |

| US1514224 * | Jan 3, 1881 | Nov 4, 1924 | Aiilis | Office |

| US2054326 * | Nov 27, 1933 | Sep 15, 1936 | Nordberg Manufacturing Co | Water seal for use with crushing machinery |

| US2484971 * | Jun 10, 1946 | Oct 18, 1949 | Traylor Jr Samuel W | Gyratory crusher with lubricated dust seal |

| US2489936 * | Jun 9, 1947 | Nov 29, 1949 | Nordberg Manufacturing Co | Seal assembly for gyratory crushers |

| FR513401A * | Title not available | |||

| FR850650A * | Title not available | |||

| GB630978A * | Title not available |

| Citing Patent | Filing date | Publication date | Applicant | Title |

|---|---|---|---|---|

| US3771735 * | Dec 21, 1971 | Nov 13, 1973 | Kloeckner Humboldt Deutz Ag | Gyratory crusher with labyrinth seal between eccentric drive and crushing cone |

| US3774857 * | Aug 30, 1971 | Nov 27, 1973 | Kloeckner Humboldt Deutz Ag | Large gyratory crusher |

| US4065064 * | Oct 19, 1976 | Dec 27, 1977 | Fuller Company | Liners for crusher |

| US4179076 * | Jul 24, 1978 | Dec 18, 1979 | Babbitless | Sealing device between the movable crushing member and the body of a giratory crusher |

| US4192472 * | Apr 17, 1978 | Mar 11, 1980 | Johnson Louis W | Cone crusher |

| US4410143 * | Sep 26, 1980 | Oct 18, 1983 | Allis-Chalmers Corporation | Main shaft assembly for a gyratory crusher |

| US4477031 * | Apr 19, 1982 | Oct 16, 1984 | Iowa Manufacturing Company | Apparatus for ready conversion of crushing cavity configuration in a cone crusher |

| US8070084 * | Feb 5, 2010 | Dec 6, 2011 | Metso Minerals Industries, Inc. | Spider having spider arms with open channel |

| US20110192927 * | Aug 11, 2011 | Metso Minerals Industries, Inc. | Spider having spider arms with open channel | |

| EP2647438A1 | Apr 3, 2012 | Oct 9, 2013 | Sandvik Intellectual Property AB | Gyratory crusher frame |

| EP2647439A1 | Apr 3, 2012 | Oct 9, 2013 | Sandvik Intellectual Property AB | Gyratory crusher frame |

| EP2774683A1 | Mar 8, 2013 | Sep 10, 2014 | Sandvik Intellectual Property AB | Gyratory crusher spider arm shield |

| EP2859951A1 | Oct 11, 2013 | Apr 15, 2015 | Sandvik Intellectual Property AB | Gyratory crusher spider arm shields |

| WO2013149814A1 | Mar 18, 2013 | Oct 10, 2013 | Sandvik Intellectual Property Ab | Gyratory crusher frame |

| WO2013149819A1 | Mar 19, 2013 | Oct 10, 2013 | Sandvik Intellectual Property Ab | Gyratory chrusher frame |

| WO2014125162A1 * | Jan 17, 2014 | Aug 21, 2014 | Metso Minerals, Inc. | One-piece shield for a gyratory crusher |

| WO2014135306A1 | Jan 27, 2014 | Sep 12, 2014 | Sandvik Intellectual Property Ab | Gyratory crusher spider arm shield |