Table of Contents

In “ Sorting Before Sizing ” (a paper first announced at the Pittsburgh meeting, but delayed in preparation and now presented at the present meeting) it is shown that if slime-tables are to do their best work on slimes below 0.5 mm. or 0.02 inch in diameter, they must be carefully sorted or classified, and fed to a series of tables suitably adjusted to the different slime-sorts. The reason is that the coarser and finer slime-sorts require respectively different adjustments of the tables. Hence, if the two are fed together upon a table which has, as nearly as may be, average adjustments, fine galena, for example, will go into the tails, or coarse quartz into the heads, or both—losses which could have been largely prevented if the slime had been carefully sorted and each sort sent to its own slime-tables.

As indicated in the paper just mentioned, the present tendency in this country is generally to do away with slime-sorting or “ classification,” and simply to take the overflow from the hydraulic classifier and divide it among the tables by means of a distributing-tank. We must therefore look to the old country to see what means of slime-sorting have been approved.

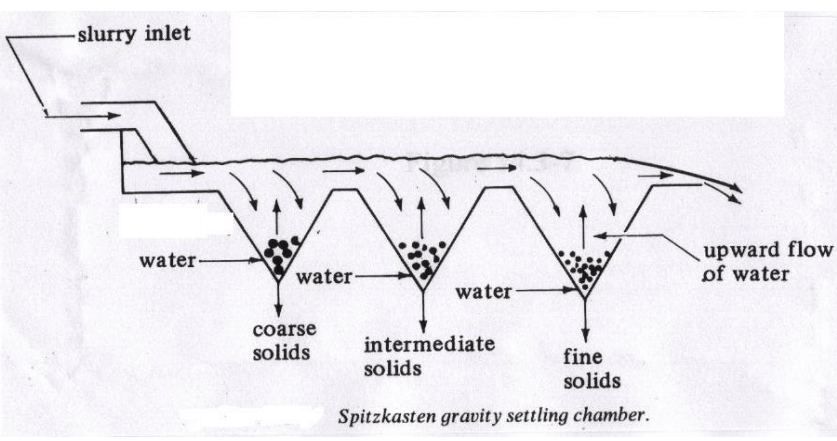

The Spitzkasten is the only apparatus recognized by such authorities as Rittinger and Linkenbach. Reducing Rittinger’s Austrian measures to metric units, we find that in 1866 he recommended for 100 liters per minute of slime the following dimensions :

And so on. As each new box is added, it widens in geometrical progression, and lengthens in arithmetical progression, the pointed boxes; twice the quantity of slime will require twice the width throughout, the length remaining the same.

Linkenbach (1887) recommends for 100 liters per minute of slime :

With the same rule for increased quantity. Both authorities declare that 50° is the minimum angle that can be allowed for the sides of the box, but their diagrams mostly show as much as 58° for the minimum angle.

Rittinger, who was the inventor of the Spitzkasten, describes its action as a separation in a horizontal current according to the law of equal-settling particles. In the light of recent investigations we prefer to use the term “ free-settling.” He says, further, that, in order to prevent slime from depositing, the sole of the feed-distributor should descend to the inlet of the box at an angle of 1° 15′, or 0.25 inch to 1 foot for the coarser sorts, and 0° 6.25′ or 0.02 inch in 1 foot for the finer sorts, and should enter at the exact level of the exit. Linkenbach favors raising the sole of the feed-distributor to 1 or 2 inches above the entrance, for the same purpose.

For the last box, Rittinger favors destroying the surface-current by an inverted dam, making thereby a settling-tank of this box. Linkenbach favors cutting up the boxes, when they are large, into two smaller sets, thereby discharging the spigot- products at a higher level, and diminishing the weight of the loaded apparatus.

Both authorities make note of the fact that the Spitzkasten gives only an approximation to true sorting according to the law of free-settling particles, but neither authority tells wherein, or how far, the Spitzkasten departs from perfect sorting.

In these directions the authors have sought to supply some missing data, and the lines which their investigation has taken are:

I. —The horizontal current; what is its form and what becomes of it ?

II. —The feed-distributor; what is the effect upon the current of varying the angle of slope of the feed-sole ?

III. —Can the current be so confined as to make it a true horizontal current ?

All these investigations require some means of coloring the liquid composing the surface-current, of seeing it when it has been colored, and of picturing it for future study and comparison. Milk of lime, added to the water, was found to be the best coloring-matter; a tank with one side of plate-glass permitted the colored current to be seen, and photography furnished the means of preserving its form, so that it could be studied at leisure.

The tank which served for a pointed box is 47.5 inches long, 23.75 inches deep and 8 inches wide (inside measures). The outlet is 2.375 inches below the top of the tank. It has a plate-glass front, and is otherwise painted black inside. Within it are two cross-partitions, 17 inches long and 8 inches wide, sloping 58° from the horizontal. One, called the tail-partition, slopes downwards and inwards from the outlet; the other, called the head-partition, slopes downwards and inwards from the end of the feed-sole at the inlet. Both are bevelled, to give a sharp, true edge of contact. They are loaded with lead, to sink them; suspended by fine wires, to support them; and wedged in place and made practically water-tight at the sides by tacking on a strip of gunny-sack. The feed-sole, 12 inches long by 8 inches wide, is packed and held by the same means as the partitions. Water is brought by two hose-pipes and distributed by two pipes with many holes, to give an even current.

Thus made, our Spitzkasten is like that of Rittinger in every respect, except that we used no spigot to discharge water below, and our sides are vertical (which, indeed, is the case also in some of Rittinger’s boxes).

As representing nearly the speeds of the three boxes of Linkenbach for a width of 8 inches, three rates of current were selected, namely, 190, 126 and 85 pounds of water per minute respectively.

In our experiment the water was weighed with bucket and spring-balance. The feed-sole was placed horizontally and on a level with the outlet.

In each experiment the water-quantity was measured; the water-current was allowed thoroughly to establish itself; the milk of lime was added till it had just defined the main currents ; and the flash-light picture was then taken.

Form of the Current

These experiments are shown in Plates I. and II., Plate I. exhibiting the current of 190 pounds and Plate II. that of 85 pounds of water per minute. These plates show, in the first place, that the surface-current has the form of a wedge, widening (i.e. deepening) towards the outlet, and having, for the current of 190 pounds per minute, an apex-angle of 11°, and for 85 pounds 24.5°. The angle found for the 126-pounds current (not illustrated by a plate) was 16.5°. The water composing these wedges is most rapid on the surface (where the friction of the air maybe disregarded), and the surface-velocity is: For 190 pounds per minute, 10.84; for 126 pounds, 8.29; and for 85 pounds, 7.05 inches per second. The velocity decreases with increasing depth, until at the bottom of the wedge it does not exceed: For 190 pounds per second, 3; for 126 pounds, 2; and for 85 pounds, 1 inch per second.

These wedges are the result of the mixing of the so-called stagnant water below with the surface-current by an action to which we shall refer as head-suction, or upward current on the head-partition, which widens them and slows their speed.

In the second place, it will be noticed that there is a wide under-current or eddy, returning down the slope of the tail-partition, and carrying with it a portion of the slime, which should be taken to the next box of the series, but which passes instead down the tail-partition to the bottom and then up the feed-partition to rejoin the wedge. This current shows much more plainly in Plate I. than in Plate II. In the latter, the lime had not quite reached it when the picture was taken. From this undercurrent the spigot obtains its water-supply, and the fine slime contained therein joins with and contaminates the slime-sort which rightly belongs to that spigot.

Thirdly, we notice in each of the plates that there is a top-layer which passes off at the outlet.

An approximate estimate was made of the two quantities: namely, that going over the outlet, and that passing down in the under-current. In Figs. 1, 2 and 3 the horizontal dimensions represent velocities; the vertical dimensions, the thickness of the two currents. The former were measured during the experiment, and the latter on the plates. Fig. 1 represents the feed-current of 190 pounds of water per minute; Fig. 2 that of 126 pounds; Fig. 3 that of 85 pounds. From these dimension and the width of the Spitzkasten (8 in.) we can compute the following values :

These results were checked by weighing the overflows with scales, the result being :

We get also as the measurement of the under-current :

These figures show an extraordinarily large quantity of slime-charged water sent down into the stagnant pool in proportion to the feed and overflow. There are, to be sure, errors in the computation. For example :

(1) The mean velocity of the top-layer for the whole length is used for the top-measure, while the point under discussion is out where the wedge forms a junction with the tail under-current, and this velocity would be less than the mean; (2) the line a b is assumed to be a straight line, while it may not be so. Neither of these errors is believed to affect seriously the result, which shows that the quantity of slime-charged water going away by the overflow is much smaller than that going down to revolve around in the stagnant pool. It is true that the upper layer is probably much more concentrated than the lower, and this fact is in favor of the apparatus. We note also that while the high speed (190 pounds) makes a narrower angle of wedge than low speed (85 pounds) it nearly nullifies this advantage by the high speed of the tail-undercurrent.

The authors are of the opinion that a flat layer which comes in at the feed and goes out at the outlet without forming a wedge with its tail-undercurrent and head-suction is the ideal condition to be attained, if possible, and that the more any particular form departs from that ideal the more unsatisfactory it is.

The Slope of the Feed-Sole

A series of trials was made to get the best slope of the feed-sole. The angles tested were 0°, 5°, 8°, 10°, 15°, 20°, 25°, 28° 30′ and 30°. Of these, 5° to 10° gave the narrowest angle of wedge with all the different water-quantities. This conforms with Rittinger’s and Linkenbach’s requirement, namely, that fine slimes must be prevented from settling on the feed-sole.

Plate III. represents the current of 190-pound water, with 5° feed-sole slope. Angles larger than 10° tended to widen the wedge somewhat, and showed no gain to compensate for the loss of head. When 30° was reached a curious change took place. The whole current followed down the slope of the head-partition and formed a head-undercurrent, that is, a current at the feed-end, like that shown in Plate IV. Since 30° is more than half of 58°, the sole was set at 28° 30′, or about one-half of 58°; and the curious phenomenon was then observed that the feed-current was indifferent as to which of the two ways it would go, namely, as a head-undercurrent or as a horizontal surface-current. By placing a bit of iron-plate under it, it could be guided to become a surface-current, and by placing the sheet-iron over it at the proper angle, it could be deflected downwards and become a head-undercurrent. But it absolutely refused to take any intermediate position. It was either surface-current, like Plate I., or under-current, like Plate IV., and, when once directed, it would continue to flow, as directed after the guide-plate had been removed.

Next a special set of variations in feed-slope was tried, comprising the following forms:

- A catenary curve having 6-inch drop and 6-inch advance.

- A cycloid curve, drawn by 6-inch circle, rolling on a straight line.

- A horizontal feed-sole, depressed 1 inch below the overflow.

- A horizontal feed-sole, raised 1 inch above the overflow, and meeting the head-partition at an obtuse angle of 122°.

- A horizontal feed-sole, raised 1 inch above the overflow, its end being cut off square.

The catenary (No. 1) gave a higher speed than the 5°-slope feed-sole; but no gain in angle of wedge or diminution of tail- undercurrent was observed.

The cycloid (No. 2) gave the most rapid current of all; but no gain in wedge-angle or diminution of tail-undercurrent was observed.

When the horizontal feed-sole was depressed 1 inch (No. 3) it gave a wedge-angle of 25° for 190 pounds water, which was wider and more unsatisfactory than that shown in Plate II. for 86 pounds.

When the horizontal feed-sole was elevated 1 inch (No. 4) above the outlet, and the feed-sole and head-partition met at an edge obtuse angle of 122°, there resulted a head-undercurrent, shown in Plate IV., like that given by a 30°-slope, the horizontal current having disappeared altogether.

When the horizontal feed-sole was elevated 1 inch, but the end of the board was sawed off square (No. 5), a case of equilibrium was presented like that of the feed-sole sloping 28° 30′; a plate-iron guide could cause it to establish either a surface- current or a head-undercurrent, and, once established, the water would flow on in the course allotted to it, until it was disturbed.

Our conclusion is that a flat feed-sole, sloping 5°, and joining the head-partition at the level of the overflow, will give the best results.

By the experiments recorded above we are satisfied that the Spitzkasten is not a scientifically exact instrument. The trommel, jig, Spitzlutte and separator, when well constructed, and the slime-table, when properly adjusted, are all scientifically accurate instruments; that is to say, when fed with suitable material, and not overfed, they will all do perfect work. They depart from scientific accuracy only through over-feeding, or through the feeding of material that is not susceptible of perfect work, or through imperfect construction. The first two of these causes are due to the demands of commerce; the last, to ignorance.

The Spitzkasten, on the other hand, is scientifically imperfect. It cannot be fed with such a product, or at such a speed, or so adjusted to suit its feed, that it will do perfect work. There is always the tail-undercurrent to contaminate the product from the spigot.

Can this defect be cured in any way ? Three means have been considered, consisting in the use, respectively, of

a. A balanced hydraulic water-supply;

b. An upward current of hydraulic water

c. A perforated board

Under a and b, by balanced hydraulic water is meant an addition of hydraulic water, which will exactly supply the spigot with the right quantity of water, no more and no less. This is a difficult thing to do. A slight excess of water, that is, an upward current, will prevent the free discharge and cause a troublesome accumulation of products in the box; while a slight deficit will carry down contaminating fine slimes. This quantity, however, may be insignificant.

The method of applying this water by a vertical-tube inside the box is not approved by the authors, as it will seriously disturb the surface-current. If hydraulic balance-water is to be used, it should be put on outside with the T and plug or T and goose-neck discharge. The authors are of the opinion that one of these discharges, with a slight deficit of hydraulic water, is the most practical suggestion to offer.

Under c (perforated board), a 7/8-inch board was perforated with ¼-inch holes, which were 1 inch from center to center on the cross-rows, while lengthwise the rows were 1 inch apart from center to center; but the holes of one cross-row were staggered ½-inch with the holes of the next. This was done throughout to give the grains full opportunity to fall through the holes.

This perforated board was 47½ inches long, of which 12 inches was blank, and served for feed-sole, while 35½ inches was perforated, as above described. The board was placed horizontal, with its top-surface on a level with the overflow.

The apparatus was, therefore, a continuous acting Rinne (German) or run (Cornish), in which the grains suitable for deposit at any time could drop through the holes, and those not suitable could be carried forward. Plate V. illustrates a current of 190 pounds per minute. It appears very satisfactory to the eye. The mixing of fine slimes with the spigot-product is greatly reduced. The picture for 126 pounds of current was nearly as good as Plate V. But the picture, which illustrated 85 pounds current, falls away considerably, and cannot be regarded as representing good work.

This perforated board must have, at least, a balanced hydraulic water. It is quite possible that if the hydraulic is introduced in the stagnant-water space, with means to break up its current, a noticeable upward current could be used, which would go far towards keeping out altogether the objectionable fine slimes, and towards the yielding of a product truly sorted, according to the law of free-settling particles. Such a hydraulic should be applied as a horizontal current for the whole width of the box, and directly beneath the feed-sole.

The authors are aware that a perforated board has been used in France. They, however, did not know of its existence until after the work here recorded was done. They are aware, also, that the Kohinoor mill, in Missouri, has a Spitzkasten with a first box supplied with a horizontal lattice-work.