Table of Contents

Mechanism of Size Reduction

The spectrum of comminution mechanisms in a mill range from shattering of the rock by imposition of a load to abrasion by surface contact with other rocks. Since SAG represents a combination of autogenous and ball milling, a better understanding of the mechanism of the comminution process in a SAG mill can be obtained by examining first the information available on autogenous grinding.

In an interesting study of autogenous grinding in a 10-ft. dia. x 2-ft. long Cascade mill:

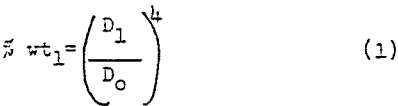

where Do: diameter of new balls to the mill

In more general terms, the Gaudin formula for comminuted particles expresses the % weight of particles reduced to size D1 as being proportional to

Where D0 represents a size modulus representing the initial size of the particles, and “n” corresponds to the inclination ∝ (n = tan ∝) of the cumulative particle size distribution in the mill after comminution (plotted on a log-log scale).

The pilot tests in the 10-ft. mill showed that when the autogenous mill was fed with a narrow fraction of particle sizes, ranging from 150-mm. to 40-mm, after comminution the inclination factor n ranged from 1.0 for the larger to 1.7 for the finer size particles.

By comparing these values of n with the value of k, which according to the juxtaposition of equations (1) and (2) would be associated with pure surface abrasion, Bergstedt and Fagremo concluded that the mechanism of comminution in an autogenous grinding mill depends principally on impact type of breakage. When a stone enters the mill, corners and sharp edges are quickly broken off and from there on the stone is reduced in size by abrasion, until impact with the liner or other stone breaks it up to smaller pieces and the “polishing off” is repeated.

Process Design Factors

As in the case of autogenous grinding, the comminution process occurring in a SAG mill is also a combination of impact and abrasion. Operating conditions, which favor abrasion, for instance low loading of small size balls, may lead to high wear of balls and liners and result in operational problems due to the buildup of coarse material in the mill and the grinding of the feed to extra fine particles, at a relatively high energy consumption. Impact breakage, on the other hand, yields a wide distribution in product sizes and minimizes energy consumption, but unless it is properly controlled it may result in cracking of the mill liners. A proper balance of the two mechanisms is, therefore, of the utmost importance. This depends on the proper design of the factors discussed below.

The length and diameter of a SAG mill are determined principally by the desired throughput capacity and the grindability of the ore. For conventional ball mill grinding, grindability is usually expressed in terms of the Bond Work Index, which is determined in laboratory tests and expresses numerically the power required to reduce rock from a large size (e.g. >10-inch diameter) to 80% passing 100 microns.

For conventional ball milling, the Operational Work Index can be related to the Bond Work Index by the introduction of “efficiency factors” as described by Rowland. To date, the authors have been unable to draw a corresponding relationship between Bond Work Index and Operational Bond Work Index for semi-autogenous grinding plants. The inability to do so appears to be related to rock competency, i.e. the fact that the work index is not constant over the range of size reduction under consideration. Hence, it is believed that the sizing of SAG production mills can only be done by extrapolation of performance data from carefully conducted pilot test work.

The critical speed of the mill is termed to be that at which the centrifugal force created by the rotation of the mill becomes equal to the force of gravity and, therefore, the material within the mill ceases to tumble.

Through operating experience, it has been established empirically that autogenous and SAG mills operate best at a speed of rotation equal to 72-76% of the critical speed. The mill speed is fixed during design and there are no SAG plants which attempt to use speed of rotation as an operating parameter. However, some Swedish fully autogenous mills are so equipped and recently Afton Mines in British Columbia commissioned an autogenous mill with variable drive.

Most SAG operations use volumetric ball charges, i.e., % of mill volume occupied by the balls including interstitial volume, of 6-10% depending on the work index of the ore to be milled and the desired throughput capacity. In addition to varying the volumetric ball charge, operators may also alter the mix of balls , depending on the work load to the mill.

For instance, at Lornex Mining, one of the most successful SAG installations, the ball load varies normally from 6-7% by volume of the mill; the ball make-up consists usually of 80% 4-inch diameter balls and 20% 5-inch diameter balls. The ratio of the larger balls is increased when the mill is processing hard ore and decreased with soft ore. The ball load can also be used to shift work from the primary to the secondary mill; a greater load of large balls results in increased impact breakage, and may produce a coarser discharge from the SAG mill.

The power input required to rotate the empty mill is termed tare power and consists of the energy for rotation plus the mechanical and electrical losses in the drive system. The cross power to the mill is the sum of the tare power plus the energy required to move the pulp within the mill.

Pilot Testing of Projected SAG Circuits

One of the conclusions reached very early in Kennecott’s investigation of autogenous and semi-autogenous grinding was that, though conventional rod and ball mill grinding circuits can be designed from bench scale test data, the design of SAG circuits required pilot testing to develop design parameters. The principal reason was that the Kennecott ores varied widely in competency, and, therefore, in their capability to act as grinding media; even within a given mine, wide variations were found between rock from different locations. This variability was sufficient to rule out the application of fully autogenous grinding and to require detailed pilot testing and evaluation of projected SAG application.

Test the various rock types to be encountered in an actual mining operating, determine the Operational Work Indices for the primary and secondary mills, and correlate Operational and Bond Work Indices as an assessment of grinding efficiency. From the data for the individual ore type samples, calculate the operating work index for grinding average mine ore in a SAG circuit and the variation in work index to be expected because of the differences in competency and work index of ore as delivered to the concentrator by the mining operation.

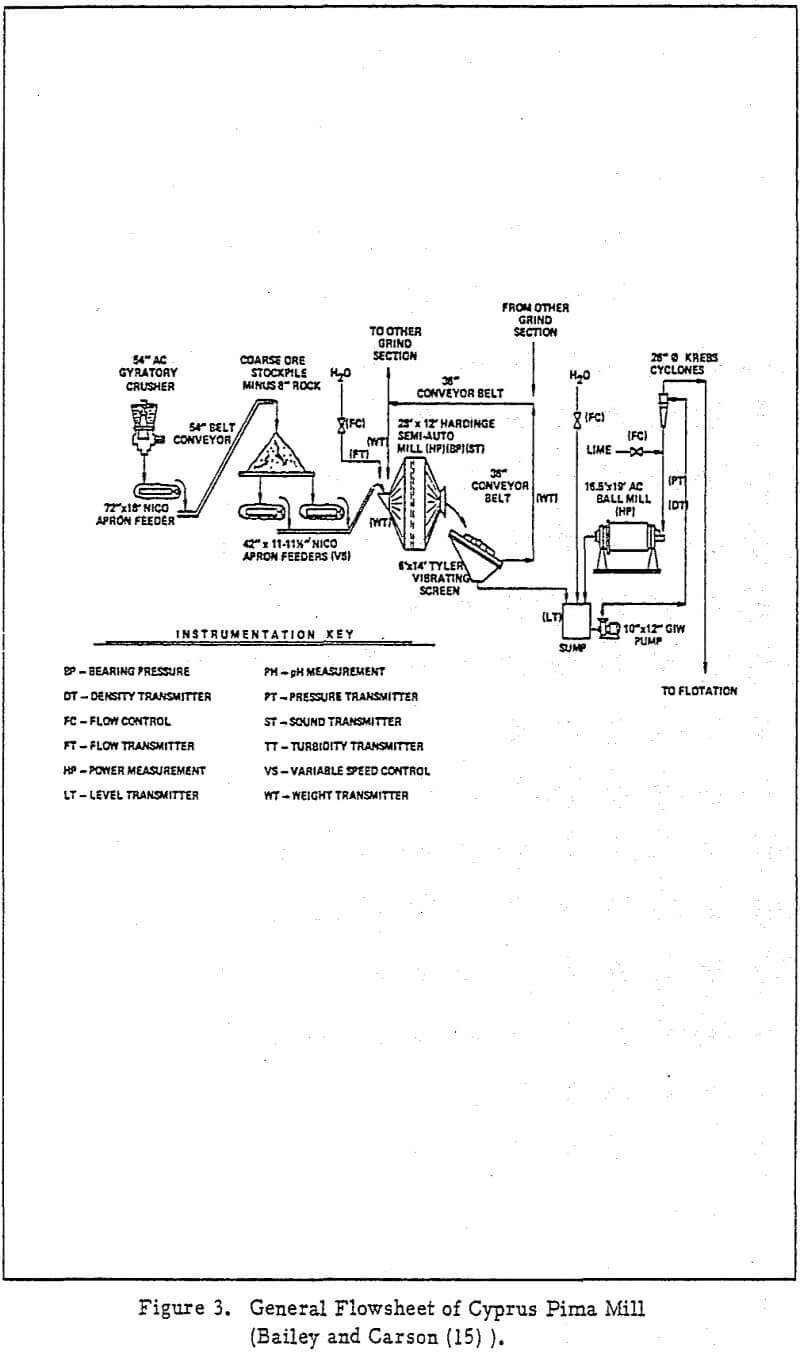

The throughput capacity of the primary SAG mill exceeds the capacity of the secondary mill and also, as expected, varies with the characteristics of the particular ore type ground and the opening of the recycle screen. Therefore, in order to match the SAG mill throughput to the secondary mill capacity, the screen undersize is split into two streams, the first used to fully load the secondary ball mill and the remainder discarded.