Table of Contents

The development of pelletizing during the last ten years has continued, however, self-fluxing pellets have not been regularly and commercially produced for use in blast furnaces, except as Kobe Steel, Ltd., Japan. This paper tells about unique developments for self-fluxing pellets, and their effects when used in Kobe Steel’s No. 3 blast furnace at the Nadahama Works (inner volume 1845 Nm³, hearth diameter 9.5 m). Several phases of the pelletizing process are discussed individually, and also their relation to performance in blast furnace operation. Special emphasis is placed on proper preparation of the limestone added to the raw materials, and indurating at optimum conditions. Means of improving pellet quality by correct control of size distribution of the raw materials used in pelletizing, and indurating temperatures, are also discussed. As basicity (CaO/SiO2) of pellets increased 0.1, coke consumption decreased 3. 8 to 4. 2 kg per ton of hot metal, when using 70% pellets in the iron burden.

Fundamental test on production method

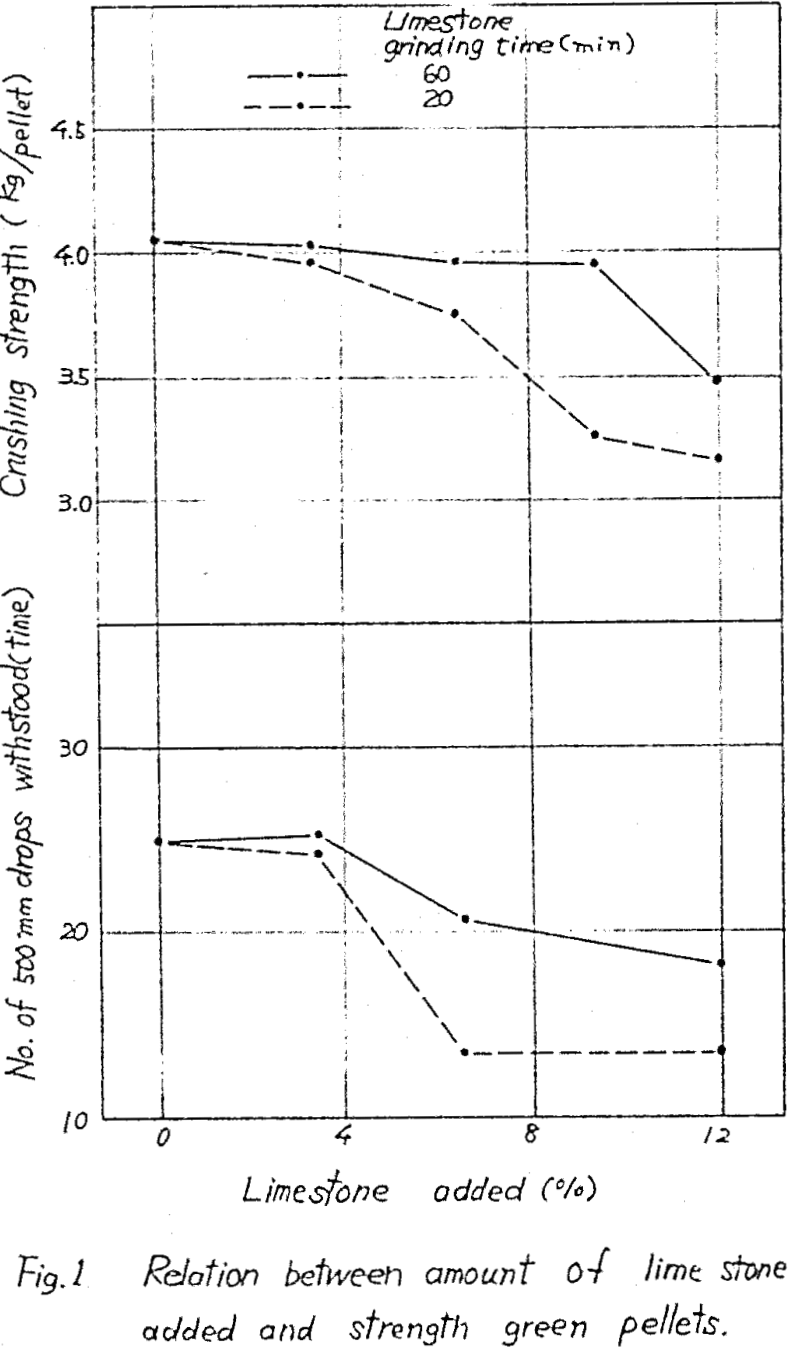

The self-fluxing pellet is made from a mixture of fine ore and ground limestone. Although it is assumed that the size and indurated condition as well as mixture rate of limestone have effects on green pellets and indurated pellets, no unanimous conclusion has yet been obtained as to what effects they actually have. Nor is there any theory established to explain chemical and mineralogycal change which pellets containing limestone undergo during a period from drying to induration.

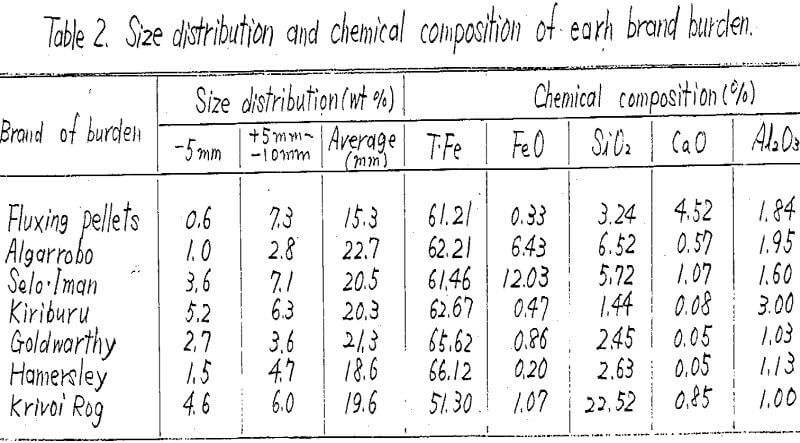

The ground ore used as raw material is a mixture of the hematite ore of Goa and U. S. S. R. (Krivoi-Rog) origins and the low-grade hematite ore of Australian (Hamersley) origin, which is a common feed to the grinding unit of the pelletizing plant. Fine magnetite concentrate used is of African (Palabola) origin. The limestone used is a domestic limestone for metallurgical applications.

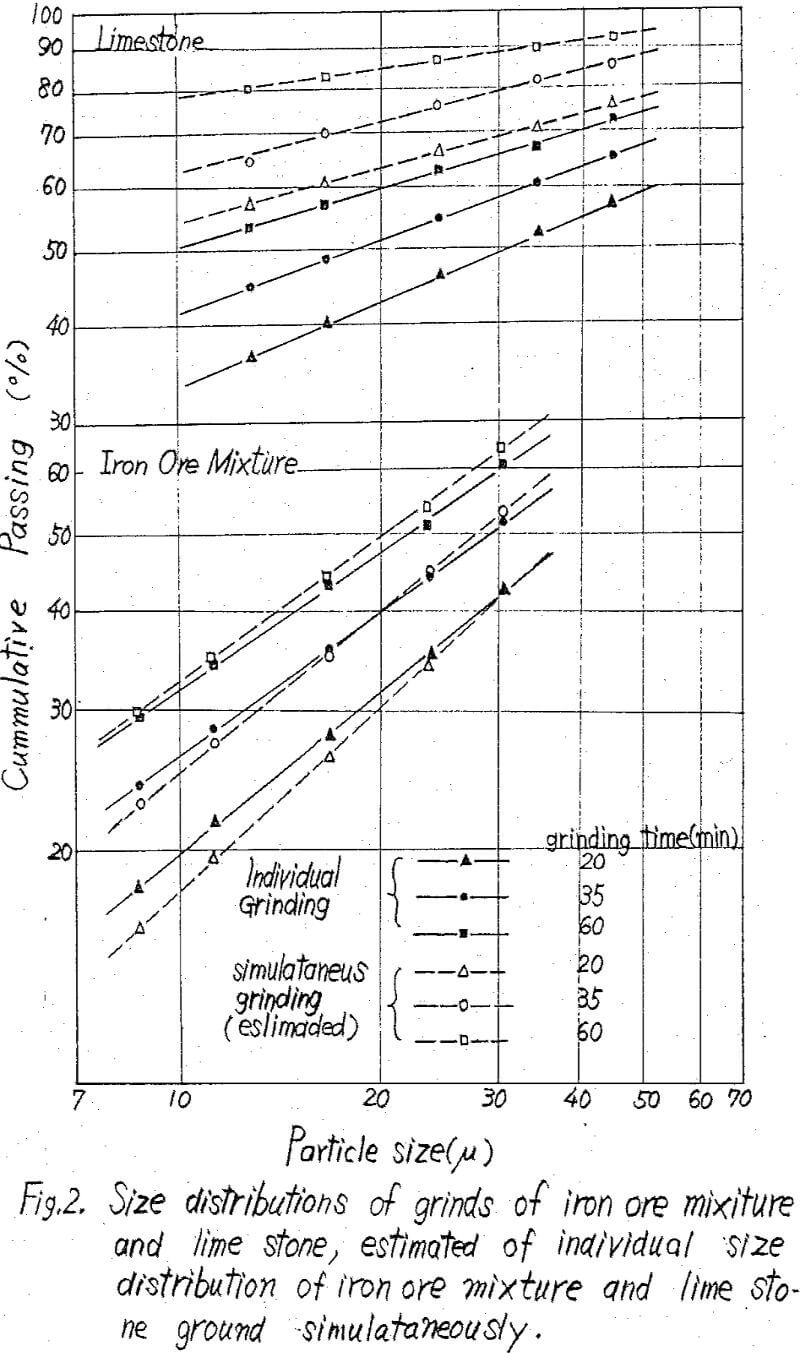

The iron ore mixture used for pelletizing consists of 70% ground iron ore mixture and 30% fine magnetite concentrate, and its size is 29.2% passing 10. The sizes of limestone used are 33.0% and 50.0% passing 10.

Each of the two limestones was added to the iron ore in the quantities of 3. 45%, 7.54%, 11.63% and 15.91% and then these mixtures of iron ore and limestone were pelletized into green pellets of approximately 16 mm in diameter by a pelletizer. The corresponding basicity to the respective, mixture rates of limestone mentioned above is 0.5, 1.0, 1.5 and 2.0.

As mentioned above, fine grinding of limestone was found necessary in the production of self-fluxing pellets. The two possible methods of grinding limestone were either to grind limestone in an independent grinding unit or to grind limestone in the existing grinding unit of the pelletizing plant together with iron ore. The latter method was thought more advantageous in that it did not require any additional facility and would also dispense with the subsequent mixing of limestone and iron ore which would be required otherwise.

The iron ore examined was the ground iron ore mentioned. Grinding was done by a laboratory ball mill (inner diameter of 180 mm, length of 190 mm). The grinding time was 20 minutes, 35 minutes and 60 minutes.

The heating speed of pellet bed decreases as the limestone content increases. This tendency is more conspicuous in the middle and bottom layers than in the top layer. It is assumed that this is because while the heating gas passes through the top layer of the pellet bed, endothermic reaction occurs on account of decomposition of limestone contained in pellets and the temperature of preheat gas thereby decreases, causing consequent temperature drop in pellets below the middle layer.

Induration tests were done using a batch type rotary kiln with an inner diameter of 600 mm and a length of 800 mm for the purpose of simulating the indurated condition to the actual operating condition as much as possible.

Reduction properties are important factors of pellet quality and must be good enough to permit the use of pellets in furnace burdens.

As it was anticipated that reduction properties, too, would be affected by indurated temperature, the relation of softening during the reducing process and reducibility, which are the representative factors of reduction properties, and indurated temperature as well as basicity was investigated.

Therefore, the relation of final gas pressure drop which is a representative factor of reduction properties, and indurated condition as well as basicity was investigated.

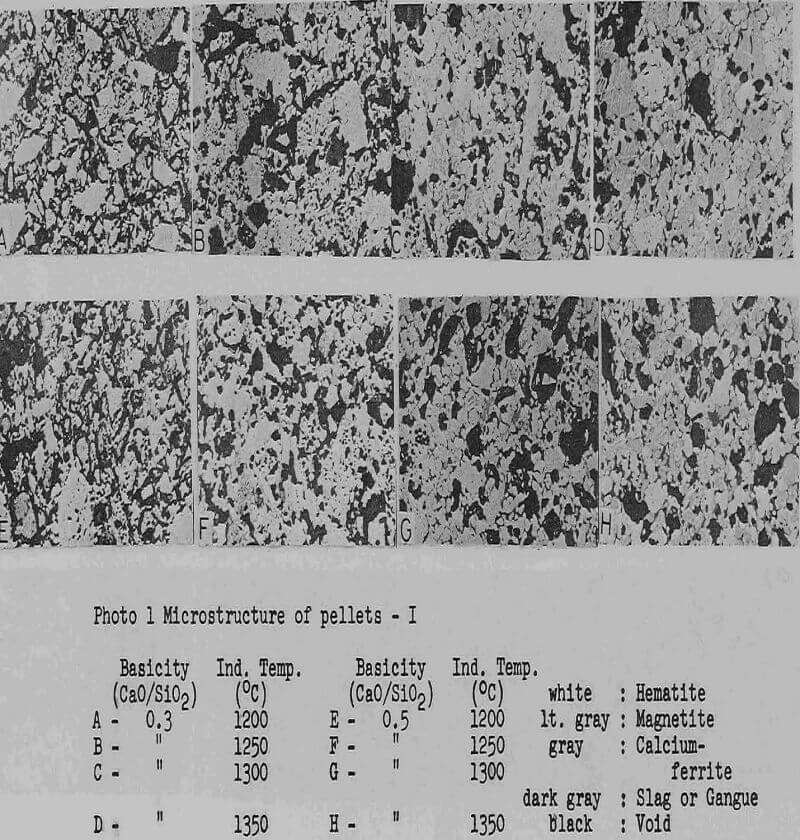

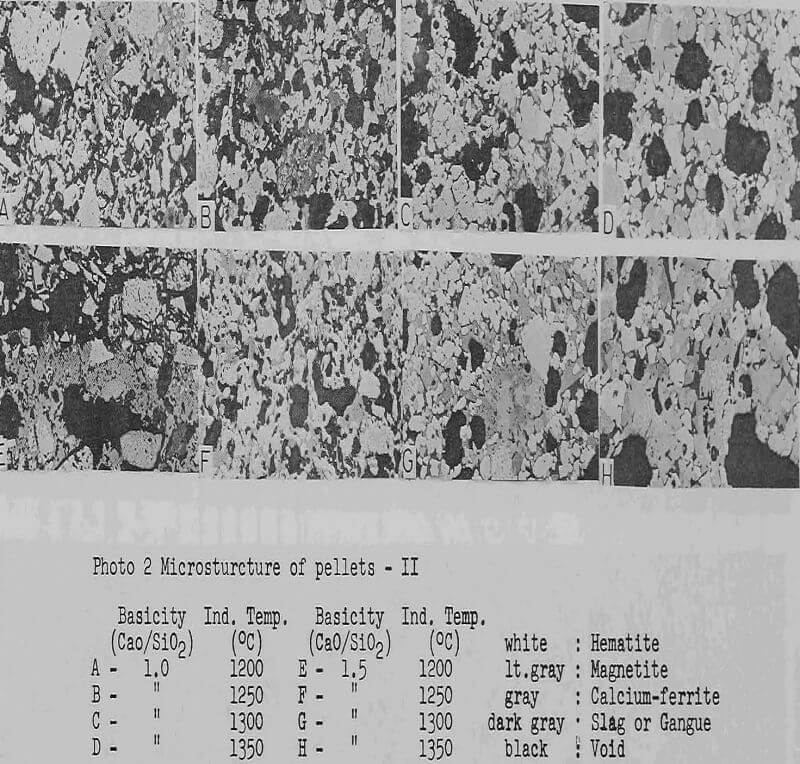

As reported previously, the microstructure of self-fluxing pellets is quite complex compared with regular pellets on account of the presence of CaO. We would like to explain the relation of indurated temperature and microstructure using indurated pellets obtained in the induration test conducted.

Problems in practical production of self-fluxing pellets

Problems in the practical production of self-fluxing pellets experienced and the relation between indurated temperature and product quality obtained from actual operating data will be next discussed.

Mixed grinding of limestone with iron ore was adopted on the basis of the test results obtained to assure an adequate strength of green pellets. An auxiliary burner was provided in the preheat section of the movable grate to compensate for heat required for endothermic reaction brought about by decomposition of limestone so that the decrease of the strength of preheated pellets be avoided.

Since an increase of sulphur content was noted with self-fluxing pellets, the behavior of sulphur in the production process of self-fluxing pellets was investigated in comparison with that of regular pellets in order to clarify the cause for the increase of sulphur content. Oxydization and decomposition of limestone were investigated at the same time.

Pellets taken from the outlets of the drying, dehydrating and pre-heating sections of the movable grate and product pellets taken from the outlets of the rotary kiln and cooler were assayed for the respective quantities of S, FeO and CO2.

Sulphur in regular as well as self-fluxing pellets slightly decreases during the dehydrating process and increases considerably during the preheating process. This increase of sulphur during the preheating process is attributed to the absorption of SO2 contained in the kiln exit gas fed to the preheating section. Desulphurization of regular pellets is carried out thereafter in the kiln sufficiently. In the case of self-fluxing pellets, on the other hand, desulphurization proceeds very slowly in the kiln. Although desulphurization goes on even in the cooler, the sulphur content in product pellets is higher than that of regular pellets. The reason for the slow desulphurizing reaction of self-fluxing pellets in the kiln is assumed to be the absorption of SO2 by free lime.

In actual operations it was confirmed that the effect of indurated temperature on pellet quality is very large, as indicated by this test.

Experimental use of self-fluxing pellets in blast furnace burdens

A series of tests to mix self-fluxing pellets with an basicity of 1.4 in furnace burdens to No. 3 blast furnace (inner volume: 1845 m³, hearth diameter: 9.5 m) were conducted for the purpose of investigating the effects of self-fluxing pellets on blast furnace operations as well as the advantages of self-fluxing pellets over regular pellets

In spite of our efforts to make the operating condition during the test periods as constant as possible, the blast volume in the fourth period was lower than in the other periods because of an increase of atmospheric temperature from 25°C to 30°C and leakage of blast, both on account of the fact that the blast volume of 2940 Nm³/min was at the maximum capacity of the blower. Therefore, the data obtained from the fourth period was treated as only reference data in evaluating the test results.

The increase of pellet mixture rate improves permeability in spite of the increase of ore/coke, since it uniformalizes the gas distribution. This is largely due to the fact that the range of the size distribution of burden becomes narrow and the content of fines (-5 mm) decreases.

The pig iron production and production rate increased as the pellet mixture rate increased since it improved permeability and reducibility of burdens. However, we failed to obtain favourable operation data for the 80% mixture rate of pellets during the fourth period because the blast volume decreased for the reason mentioned above.

The increase of pig iron production per 1% increase of pellet mixture rate on the basis of the pig iron production for the 54.1% mixture rate obtained during the first period was calculated to be 5.5 t/d for the second period and 6.38 t/d for the third period, representing the overall increase rate of pig iron production per 1% increase of pellet mixture rate being 0.17 0.19%.