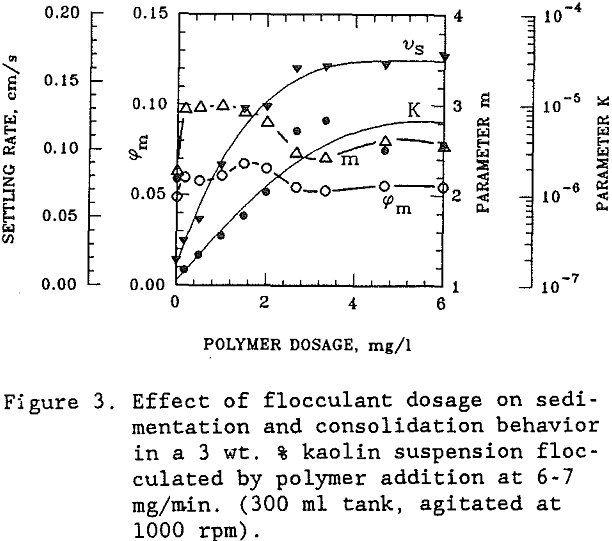

Polymeric flocculants are widely used to enhance particle sedimentation in the application of thickening processes to slurry dewatering. When properly applied, these flocculants promote the formation of large flocs which settle rapidly and provide for effective water clarification through the efficient capture of fine, suspended solids. However, the flocs formed are generally of very low density and the rapid, initial settling leads to a voluminous sediment containing a large amount of residual water.

Experimental

A systematic investigation has been carried out of the long-time settling behavior of kaolin clay suspensions flocculated under carefully standardized conditions using a commercial, non-ionic, polyacrylamide flocculant.

The investigations of the effects of sediment depth necessitated the development of special procedures. In order to isolate the effects of sediment depth from those of other variables, a procedure was developed for transferring, under carefully controlled conditions, different quantities of the flocculated suspension from the flocculation tank to a sedimentation column. The transfer was accomplished using a controlled vacuum arrangement to pump the slurry from the tank to the column.

Results

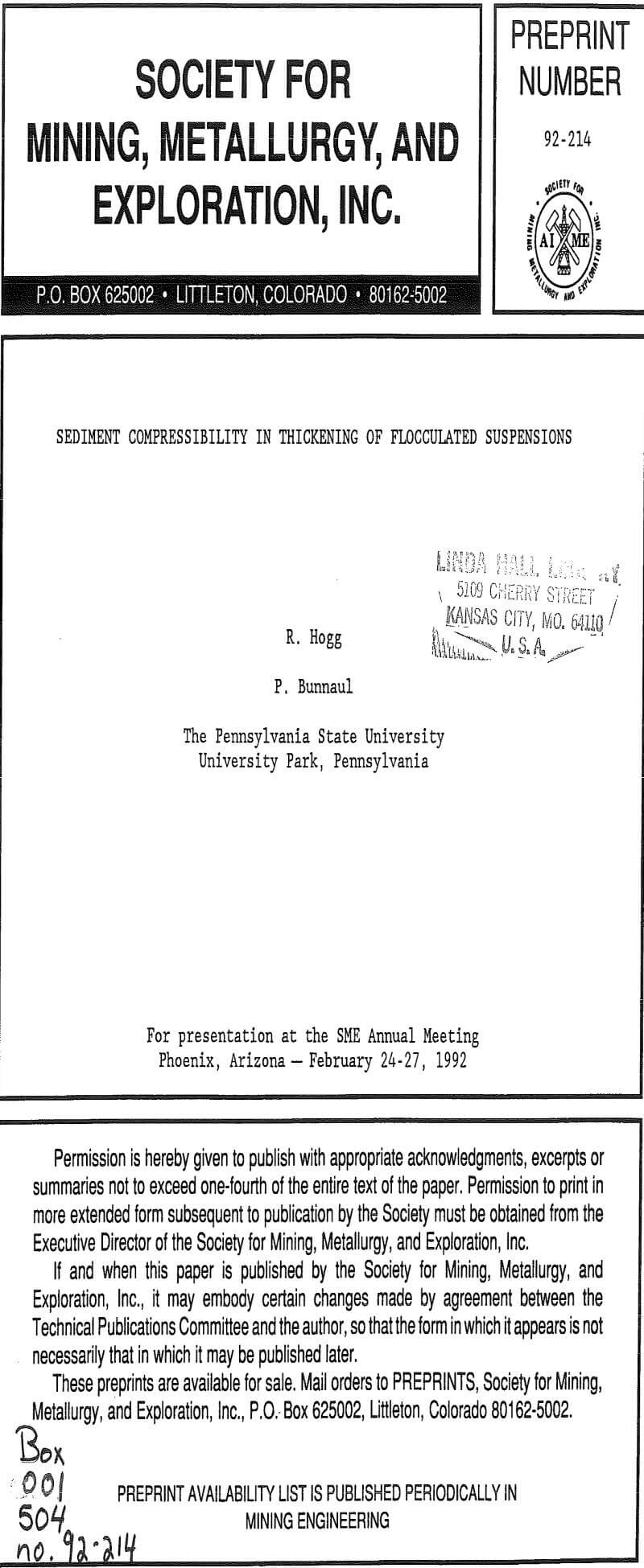

Each of the curves can be characterized by three, fairly distinct regions: an initial period of accelerating settling, a linear region corresponding to constant settling velocity and a final period of deceleration and the approach to a limiting sediment volume. Physically, the settling behavior can be interpreted as follows:

Sediment Consolidation

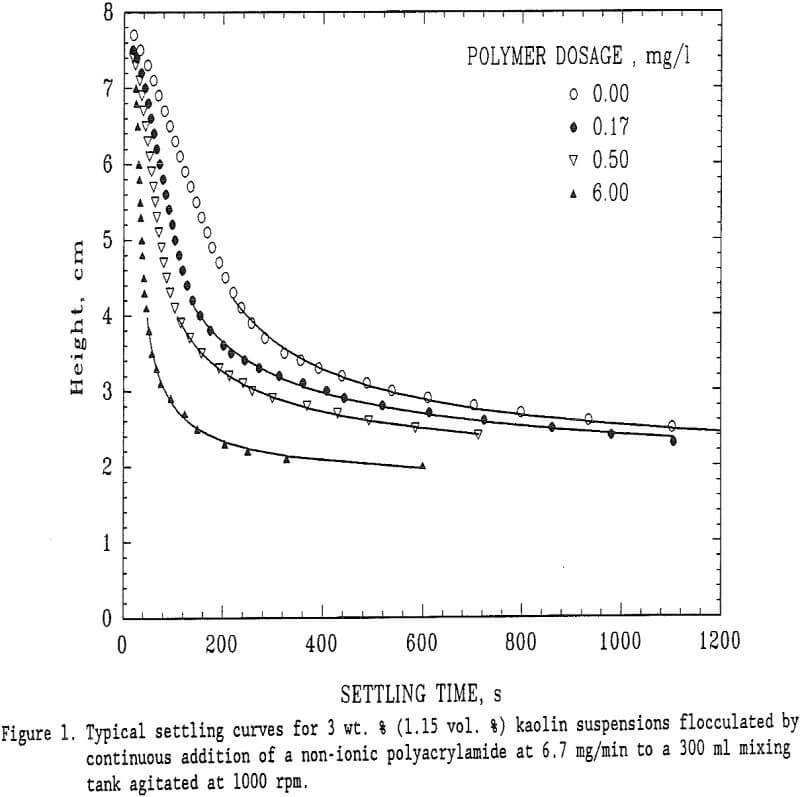

Based on the assumption that, for a given system, settling velocity depends only on solids concentration, the analysis can be used to determine the relationship between settling rate and solids concentration from a single settling curve such. Alternatively, if the relationship is known, the settling curve can be predicted.

The Kynch analysis indicates that sedimentation in an initially homogeneous suspension in which the settling velocity depends only on concentration should lead to settling curves similar to those given in Figure 1 but consisting only of Regions II and III. The time-dependent behavior shown in Region I can be regarded as an induction period during which the flocculant structure of the suspension is established. The analysis also indicates that layers of constant concentration are propagated upwards at constant velocity and follow straight lines radiating from the origin of the settling curve. The transition between Regions II and III corresponds to the time when the first of such layers reaches the mud-line. Prior to that time, the concentration at the mud-line remains constant at its initial value and the settling rate is, therefore, also constant.

Alternately, curve-fitting procedures can be used to obtain estimates of these parameters from experimental settling curves.

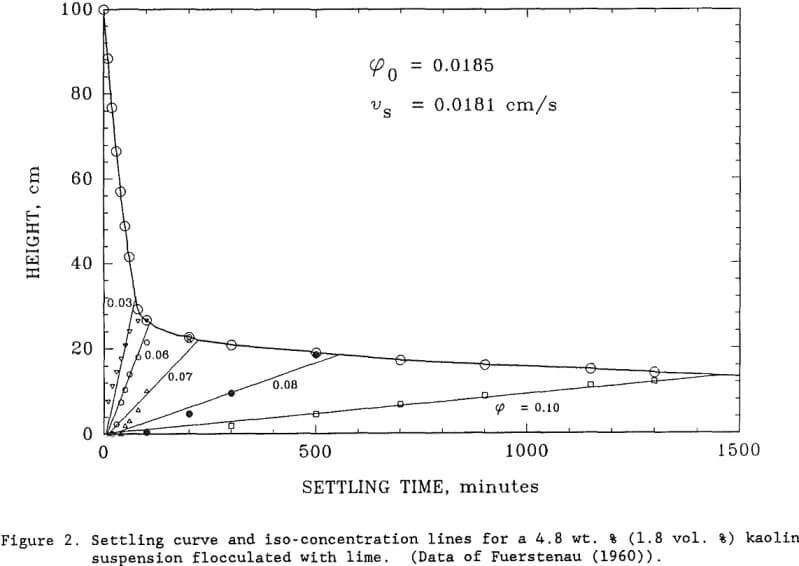

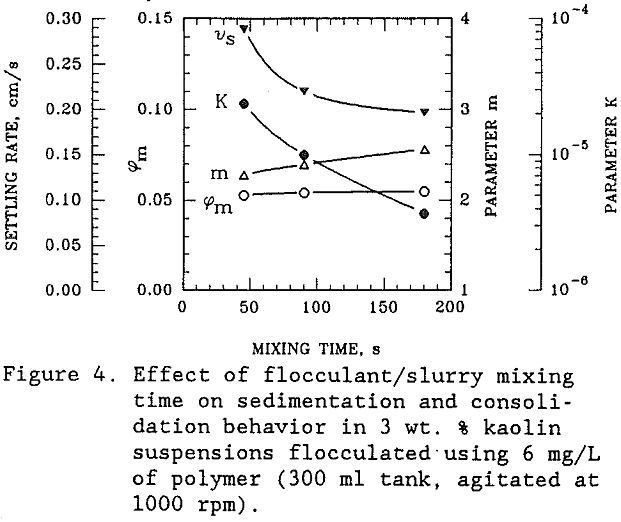

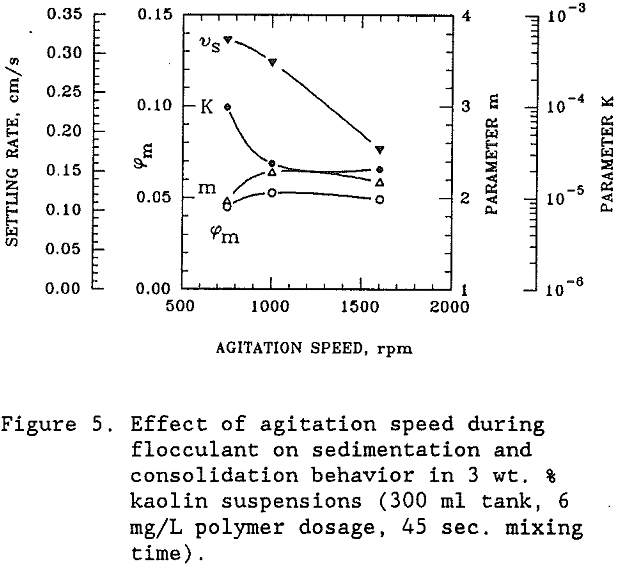

Effect of Flocculation Conditions: It has been recognized for many years that the performance of polymeric flocculants, as reflected in such factors as supernatant turbidity and initial settling rate, is strictly dependent on physical conditions (intensity and duration of mixing, for example) as well as on polymer dosage and solution chemistry.

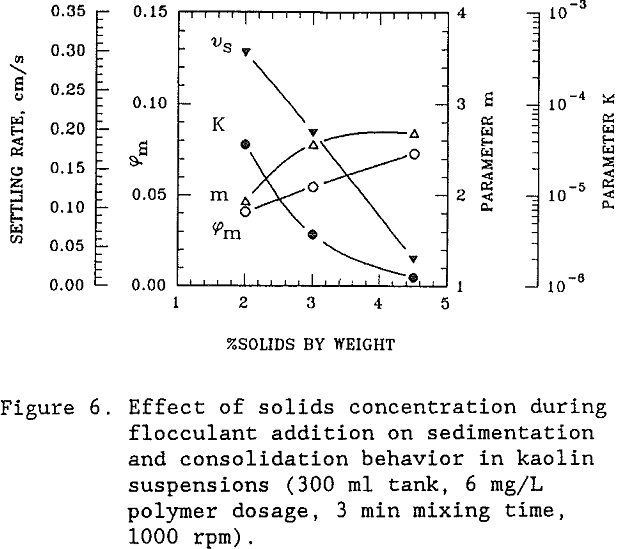

Over the concentration range studied here, the rate factors generally decrease with increasing concentration – presumably due to reduced permeability – while the concentration parameters m and ∅m both increase with increasing concentration.

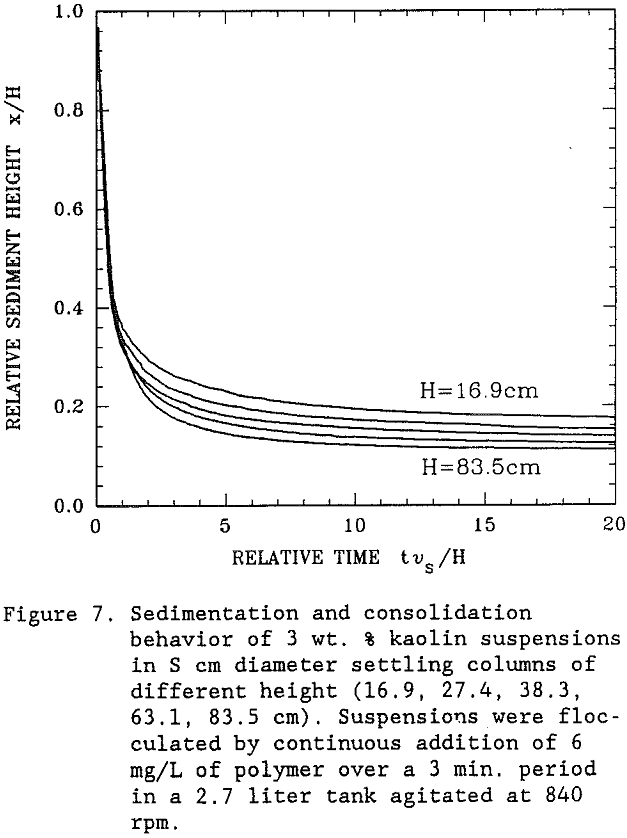

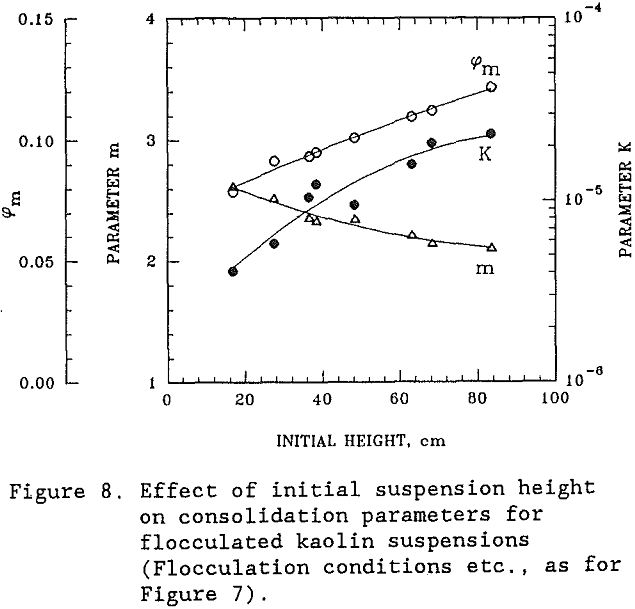

Each of the consolidation parameters can be seen to vary with total height. The most important effect, however, is on the limiting solids concentration ∅m which increases from about 0.08 in a 17 cm column to about 0.12 in an 83 cm column. The parameters k and m tend to compensate for one another and the overall fit to the data is relatively insensitive to their specific values.

Summary and Conclusions

- Solids concentration during flocculation affects the form of the sedimentation curve as well as the rates. Flocculation at higher solids concentrations appears to lead to enhanced sediment densification.

- Increased total sediment depth generally promotes sediment densification. The observations are consistent with a physical model in which consolidation is limited by the yield strength of the sediment relative to its weight.

- Sediment yield strength establishes the limits on consolidation, but consolidation rate is determined by permeability and the exudation of liquid.