The purpose of this article is to present design information and operating data on a pilot gas scrubber which is believed to be a new approach for removing noxious gases and particulate matter from the off gases of coal burning power plants and smelters.

In addition, gas scrubbers on stream or being developed for coal burning power plants and smelters have other undesirable aspects such as high pressure drop requiring high operating horsepower, relatively low gas velocities, demisting problems, and the production of slurry discharge, relatively low in solids content. This last places extra burden on settling basins, lagoons or mechanical dewatering equipment. Our design attempts to eliminate some of these undesirable aspects of gas scrubbers and to minimize others. Our concept is based on the following premises:-

- Particulate matter cannot adhere to a moving surface which is continuously bathed by a moving liquid.

- Low pressure drops across the scrubber will be achieved if the gas flow cannot pass through the aqueous scrubbing medium.

- Impingement of these gases and particulates on liquid surfaces is an efficient scrubbing procedure for the minimization of mist.

- The ability to control retention of the aqueous scrubbing medium within the scrubber independent of gravity and of gas flow rate is needed.

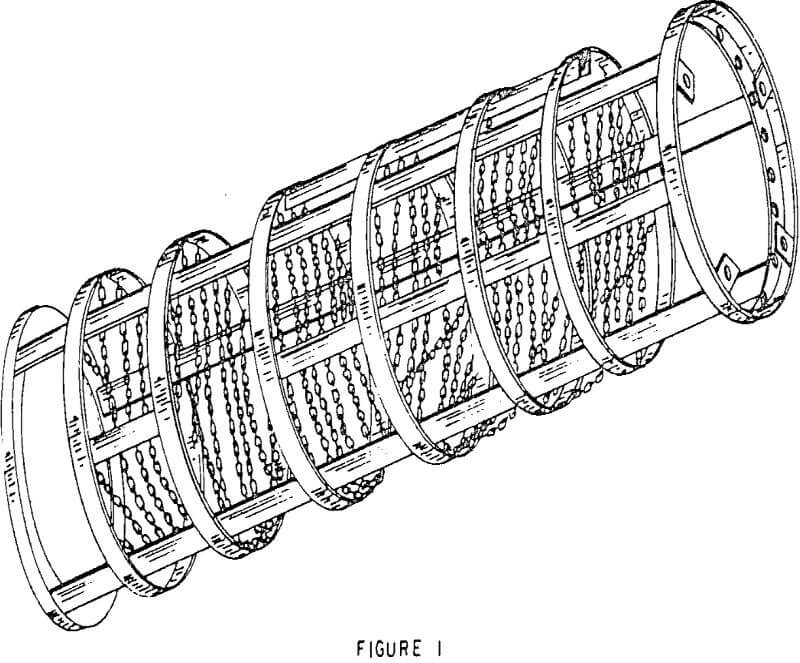

The pilot unit consists of a cylinder 3 ft ID x 10 ft in length. Instead of suspending the chains directly from the interior wall of the cylinder, they are placed in a cage arrangement. This permits easy removal of the chain assembly by sliding the cage from the cylinder. This arrangement permits quick replacement of the chain assembly with the ball assembly for which another cage was constructed. The cage for the latter is compartmentalized so that even distribution of the balls throughout the length of the cylinder is obtainable.

The principal disadvantage of the unit is that its small size renders it sensitive to gas flow rate and rotation speed relative to overall scrubbing efficiency. It has been achieving up to 85% removal of sulfur dioxide at about 1,000 ACFM gas flow with an input concentration in the range of 15,000 ppm sulfur dioxide.

It is also significant that a unit of 40 ft in length and 15 ft in diameter operating on the chain principle and at an 5 to 8 ft per second gas velocity, is theoretically capable of handling 50,000 to 80,000 ACFM of input gas at 260°F. The 40 ft length is believed to be more than ample for removing 95% of the sulfur dioxide from an input gas containing 2700 parts per million surfur dioxide. This is especially significant if the approximately 3/10 inch average pressure drop across the pilot unit does not exceed the expected 1.5 inch pressure drop for a 40 ft by 15 ft diameter prototype.