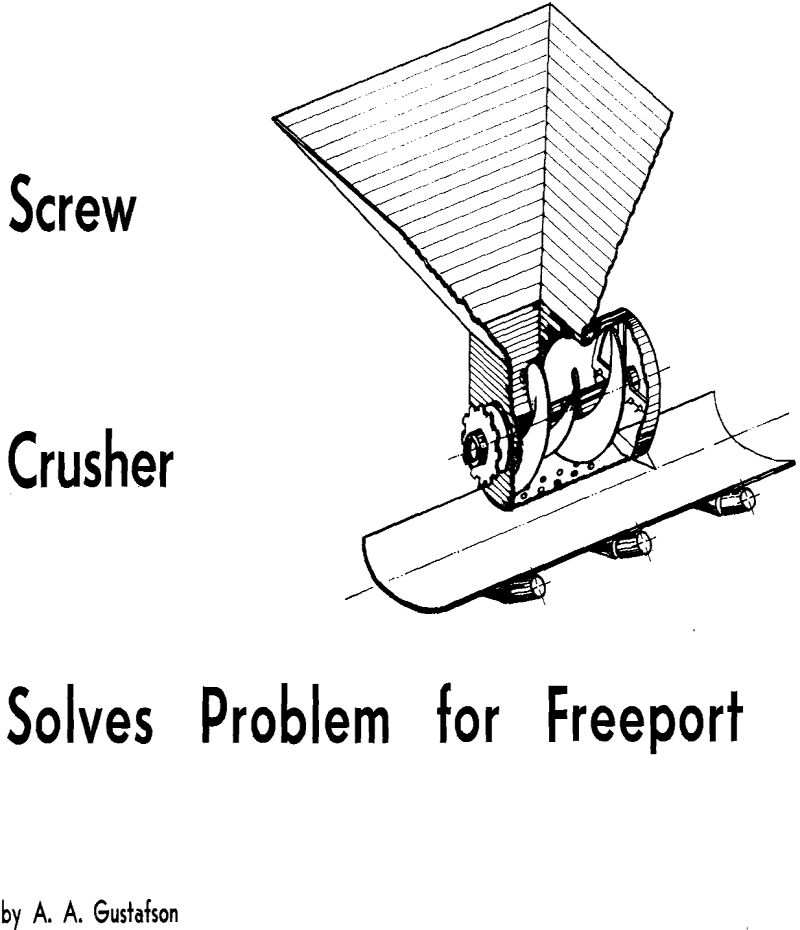

The Freeport Sulphur Co. built a portable screw crusher in 1944 that solved a problem that none of the crusher manufacturing companies contacted were able to do. Two of these crushers have now been in service for 6 years, giving satisfactory service in handling a million tons per year, and having a capacity of over 2000 long tons per 8-hr shift. These machines reduce ton size blocks of sulphur to 12 in. and also feed the conveyor system at the rate of 350 long tons per hr per machine.

The Freeport crusher consists of a screw operating in a trough welded to the bottom of a hopper. The screw also acts as a feeder to the conveyor belt, thus eliminating the usual pan feeder. The lumps that are too large to settle into the trough where the screw operates are broken off at the bottom by the screw ribbon until they settle down on the screw shaft. Then they are carried forward to the front edge of the hopper, where teeth attached to the sides of the frame split the chunks as the ribbon of the screw forces the chunks against the teeth.

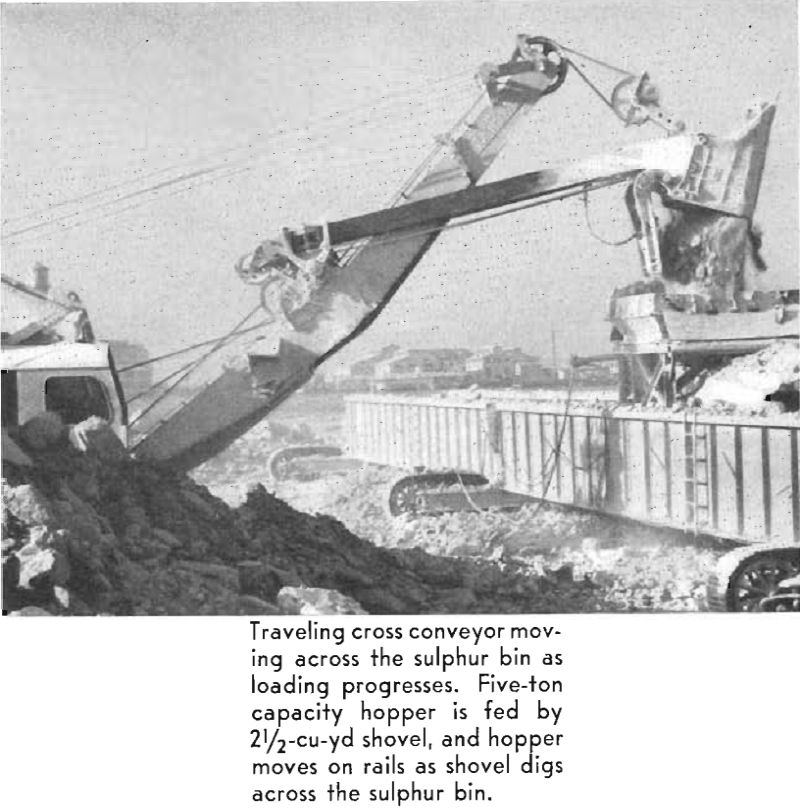

The crusher is designed to take feed 3 to 4 ft in diam and reduce it to chunks 10 to 12-in. size. The fine material is not reduced in size but fed to the conveyor belt by the screw along with the crushed chunks. The shovel dumps into a hopper over the trough which has a capacity of 5 long tons. No trouble is experienced in choke feeding the screw with this amount of material.

You can contact us here