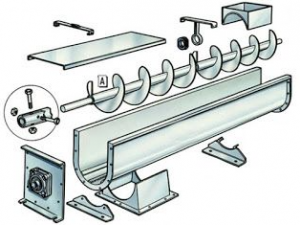

The screw conveyor consists of a spiral blade attached to a shaft which revolves in a horizontal or inclined trough. Material fed into one end of the trough is pushed toward the other end by the rotating spiral. The shaft is mounted on bearings at each end and also in the middle, if the conveyor is long. Spirals used for ores must be extra-heavy steel or cast iron.

The screw conveyor consists of a spiral blade attached to a shaft which revolves in a horizontal or inclined trough. Material fed into one end of the trough is pushed toward the other end by the rotating spiral. The shaft is mounted on bearings at each end and also in the middle, if the conveyor is long. Spirals used for ores must be extra-heavy steel or cast iron.

Drive is through a pulley or sprocket mounted on one end of the shaft.

Power consumption is high. HORSE-POWER required may be approximated by the formula: Hp. = WLC/33,000 (S.-A. catalog) where W = weight of material in pounds per min., L = length in ft., and C = 2.5 for cement, fine coal, etc.; 4.0 for ashes, sand, etc. For sand, gravel, ashes, or similar materials screw conveyors may be obtained with diameters of 9, 12, 16 or 18 in.; running at speeds of 55, 50, 45, 40 r.p.m., respectively; with capacities of 230, 510, 1100, 1360 cu. ft. per hr. respectively. Higher speeds with greater capacities are used for lighter and less abrasive materials.

Screw conveyors are useful to transport dry or moist sandy material short distances where space for other devices is lacking, e.g., to deliver return sands from a classifier to a. ball mill or as a distributing feeder for vibrating screens but wear is great both on the blade and the trough.

https://www.911metallurgist.com/bucket-elevator/