Table of Contents

In 1979, as part of its minerals environmental technology research, the Bureau of Mines began a study of mine waste tailings disposal. Part of the investigation focused on evaluating the effectiveness of the sand bed dewatering technique on alumina miniplant tailings.

Alumina wastes result from the hydrochloric acid extraction of alumina from nonbauxitic ores. These wastes are characterized as slow-settling, acidic effluents. The disposal method generally utilized is impoundment in unlined ponds lacking in drainage facilities.

Because of potential pollution problems and storage area requirements for large quantities of tailings produced, improved techniques for dewatering and decreasing seepage assume increasing importance. Sand bed dewatering is a means of providing drainage and increasing capillarity, to stabilize the top surface. Use of this method has three principal advantages: stabilization of the top surface, increased volume consolidation rates, and effluent containment when used in conjunction with pond liners.

Slurry dewatering, settling rates, increased consolidation, and decreased seepage pollution of ground waters have been the subject of numerous studies by the Bureau of Mines and private industry. Good and Fursman, reporting on centrifuge dewatering of red mud, stated that an increase of 20 pct solids was possible. Sprute and Kelsh experimented with electrokinetic consolidation as a method of dewatering lead and zinc mill tailings. They achieved up to a 16.8-pct decrease in volume. Smelley and Feld employed polyethylene oxide as a flocculant and a dewatering trommel to dewater phosphate wastes from 4 to 20 pct solids. The most recent dewatering studies were conducted by Backer and Busch on fine coal-refuse slurries. They reported a total reduction in volume of 67 pct, using a flocculant and a vertical sand drain, vertical fabric drain system underlain by a horizontal sand drain.

Industry efforts include work by Vogt and Stein on large-scale sand bed dewatering of bauxite residues. They obtained volume decreases of up to 25 pct, and a percent solids change from 20 to 37 pct. Stinson used glass columns for observing several types of red mud and found that sand-bed-drained columns were most effective in draining muds with a high percentage of fines. Techow experimented with the effects of neutralizing alkaline red muds with acidic fluoride wastes. The results showed significantly improved settling and drainage rates. Michaels and Bolger conducted research on flocculated kaolin suspensions and showed that the concentration of floccules in solution is an important factor contributing to settling and dewatering rates. Keshian and Martin used large-diameter steel pipe to simulate field conditions. The study compared theoretical predictions with actual observations of phosphate slimes.

This report represents the results of research simulating pond conditions when the sand bed dewatering technique is employed. Applications of the technique using a PVC column filled with the waste material are described.

Apparatus

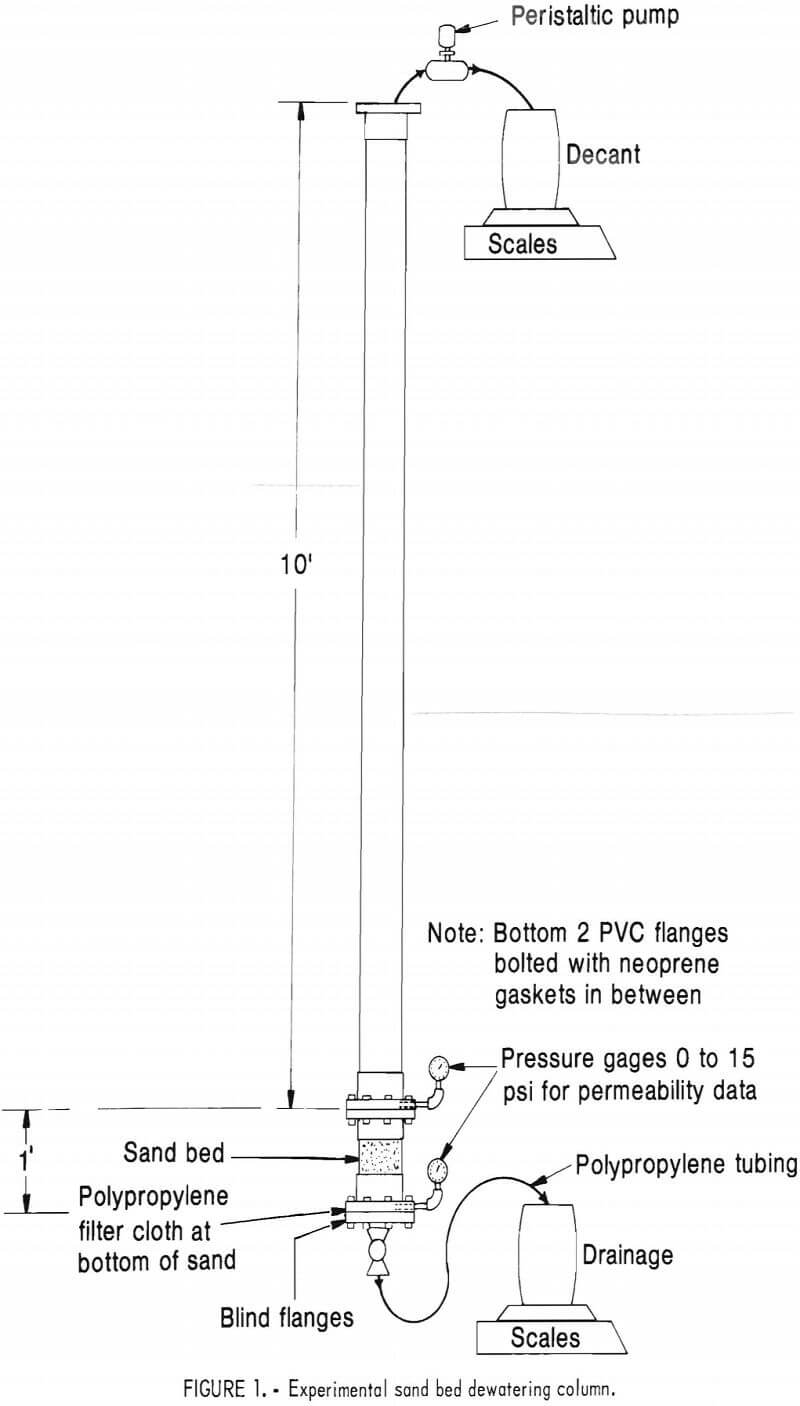

Clear 6.375-in-ID FVC pipe was used for the test column. Clear PVC assured visibility of contents and could be sectioned at any desired location for sampling. The ends of the main 10-ft section and the sand bed section were fitted with standard ANSI 150-lb PVC flanges. A blind flange bolted to the bottom of the sand bed was drilled and tapped to accept ½-in standard PVC fittings and a shutoff valve. The 1-ft- long flanged sand bed section was bolted to the bottom of the 10-ft column. The sand bed was filled with 28-mesh construction sand. The sand rested on a 6.375-in-diam circle of 10-oz polypropylene felt cloth.

Polyethylene tubing was inserted into the center of the column through the bottom flange of the 10-ft column. Holes were drilled and tapped into the blind bottom flange and fitted with a connection for securing the polyethylene tubing. The tubing was directed through a valve into an airtight 10-gal polyethylene drum.

The surface liquid was decanted with a self-priming pump into the same type of polyethylene drum as used for drainage. Decant and drainage liquors were weighed and recorded at regular intervals. Pressure gages were positioned as shown in figure 1 and were attached to the lower column flanges by PVC pipe fittings through tapped holes. Figure 2 shows a photograph of the column during operation and details sampling points. The alumina tailings slurry was introduced into the column through a feed pipe that emptied directly above the new mud level.

Materials

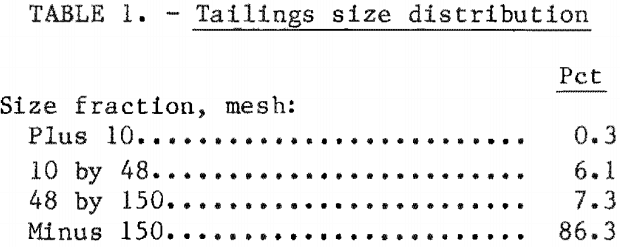

The waste material used to fill the column was from the thickener underflow in the hydrochloric acid leach circuit of the Bureau’s alumina miniplant, which extracted alumina from kaolin clay line kaolin, calcined before leaching, had an absolute density of 2.3 g/ml after grinding. The waste material could be characterized as a porous siliceous residue. Table 1 shows the size distribution of the column feed.

Procedure

Tailings received from the thickener circuit averaged 40.5 pct solids and were diluted to 23 pct solids. The column was filled in equal daily increments with the diluted slurry, containing 45 lb of dry clay. Drainage and decant weights and volumes were measured each day during the first weeks and weekly during the concluding 3 months of the test. The decreasing mud height was measured from the original filled column height and was monitored throughout the test period. Differential pressures were obtained in the sand area when the drain valve was in the open and closed positions. Physical changes such as cracking, channeling, and void bubbles in the column were observed.

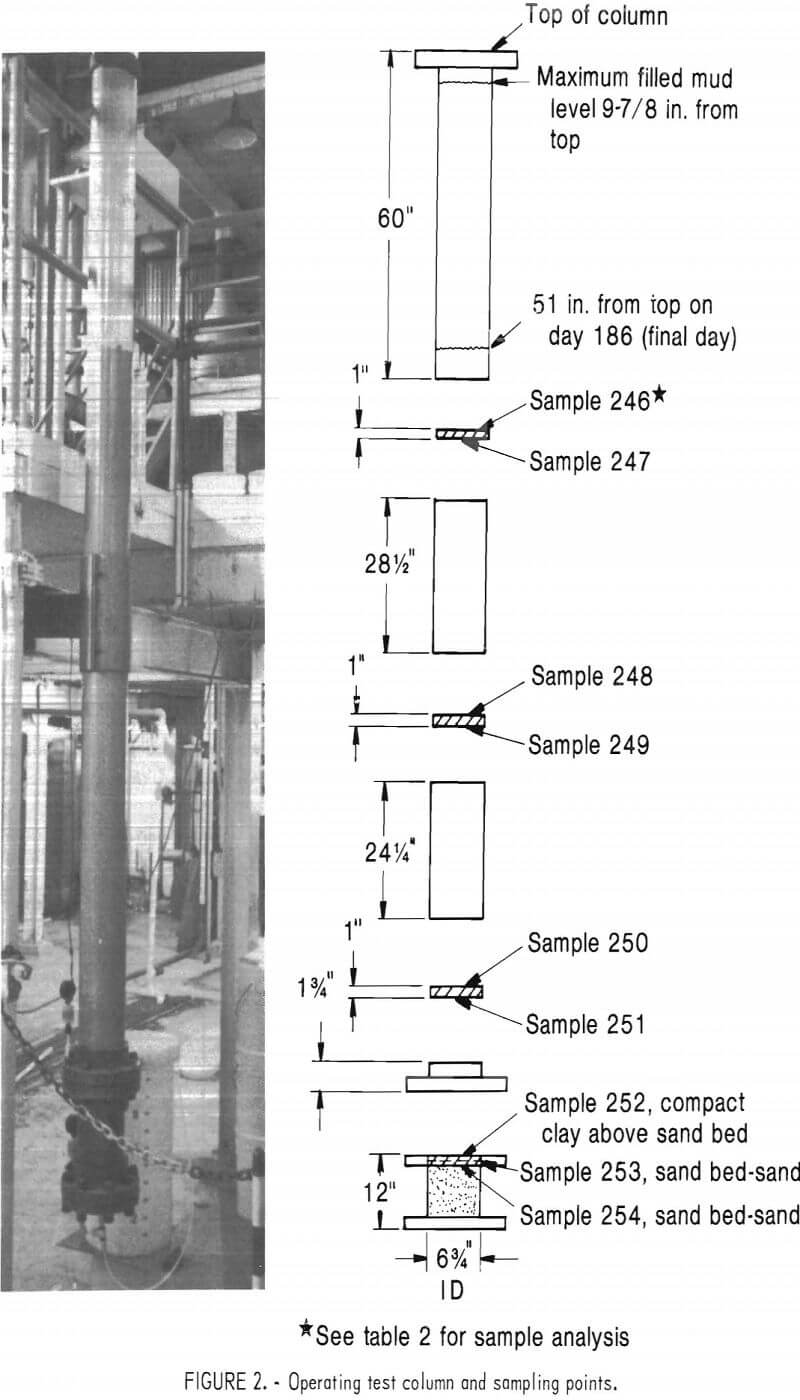

At the end of the 186 days, the column was dismantled, and 1-in-thick cross-sectional samples were cut from the pipe at locations shown in figure 2. Samples were taken for percent solids, compression testing, and chemical analysis. Percent solids were determined on column feed and on cross-sectional samples that were thoroughly washed, filtered, dried at 125° C for 24 hrs, and finally reweighed. Center and side cut samples were used for detection of possible wall effects from the small- diameter pipe.

The analytical results of column samples were derived from analysis of the sand wash liquors and the entrained liquors that washed out during the sample preparation process. The samples from the column decants, drainages, and the composite liquors were analyzed without dilution.

A compression test was performed on a 1-ft section from the bottom of the column. This section was air dried for 30 days and subjected to standard compression procedures.

Results

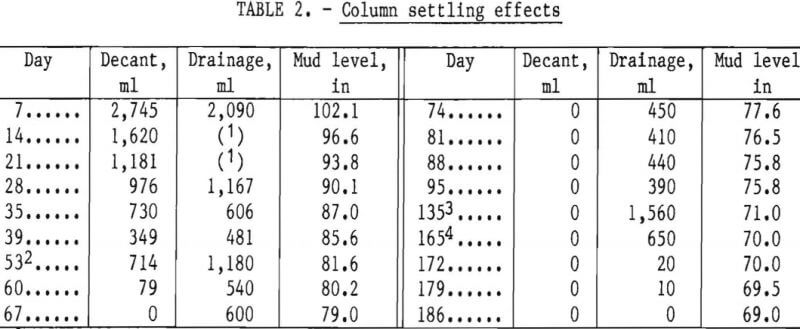

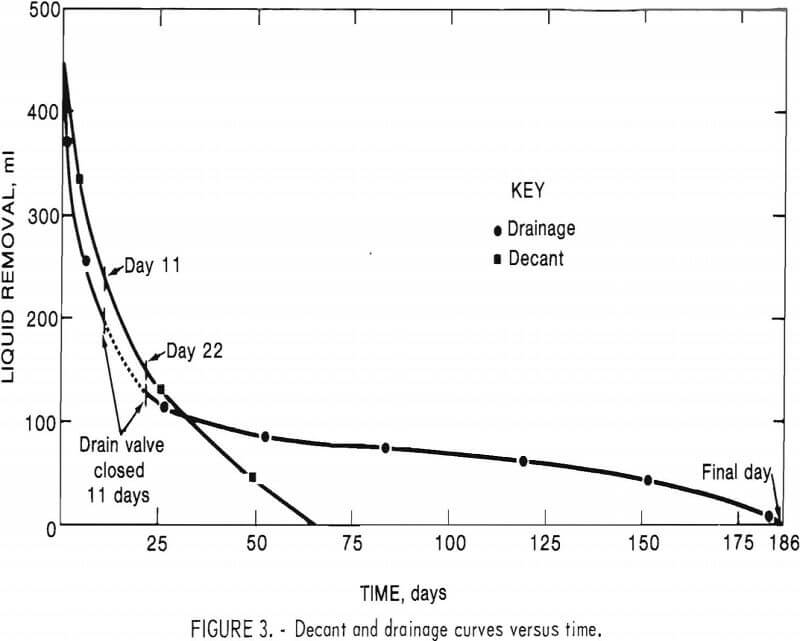

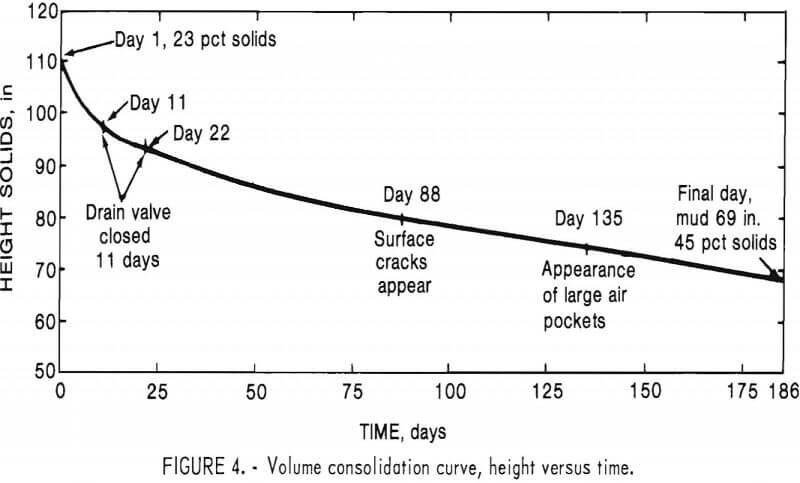

Surface liquid was present for 60 days after filling, but drainage continued for 179 days (table 2). Figure 3 is a representation of the data. The final drainage/decant ratio was 6:5. Figure 4 shows a 37-pct gain in volume consolidation.

Vertical cracking began 81 days after filling and 21 days after the last surface liquid was decanted. In 1 week, the cracks progressed downward a foot or more, and horizontal separations appeared in the central section along with many

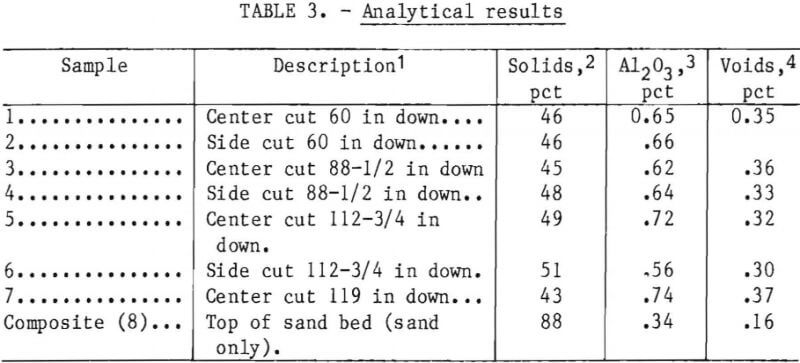

air bubble pockets ranging in size up to 3/8-in diameter. The pockets increased in number and size until the end of the test. Evaporation from surfaces exposed by cracking and channeling undoubtedly contributed to the high percent solids in the central column area shown in table 3.

The desert climate was assumed to have had no measurable effect on evaporation and drying, because the surface area inside the column exposed to the dry conditions was only 31.9 in². However, the surface area exposed to dry conditions increased when cracking began.

The void figures shown in table 3 were derived from the formula given by Dalla Valle using a dry solids density of 2.3 g/ml for dry calcined kaolin. The alumina results showed that no stratification or local concentration occurred in the waste tailing sands.

Compression tests performed on the 1-ft sections of the residue showed the air-dried cylinders would withstand loads of 62 to 74 psi before yielding.

Discussion and Conclusions

An Incremental filling technique combined with daily top liquor decantation was devised to simulate industry pond practices of daily addition of tailings slurry and removal of standing top liquors. Decantation of the supernate and the rainwater off the bed surface maximizes evaporation. A consolidation increase of 15 pct can be achieved when relying only on decantation and evaporation for dewatering.

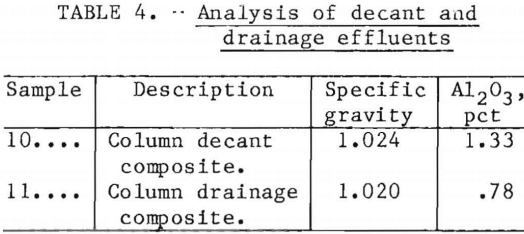

The analytical results in table 4 show that Al2O3 losses in an average tailings effluent are about 0.78 pct. Use of a lined, sand-bed-drained pond and recycling could cut the loss to nearly zero. Sand-bed-lined effluent recovery systems are environmentally acceptable, since they do not pollute the ground water and conserve water resources.

Compression tests on the dried waste residues gave a compressive yield strength ranging from 62 to 74 psi. Typically, a 36-ton, medium-sized D8 Caterpillar would exert a force of 13.2 psi, while a fully loaded front-end loader weighing 28 tons would exert a force of 34.5 psi. Dried, filled solids ponds could be reworked and reclaimed.

The consolidation curve in figure 4 shows a rapid space gain of 37 pct in the 186-day test. Stinson, working with Australian bauxitic red muds in drained sand beds, experienced less than half this gain. The comparison confirms his observations that coarser materials compress more rapidly because the calcined kaolin tailings were much coarser than red muds.

The rapid consolidation rate is of interest when comparing final tailings volume with the volume of mined clay. To produce 100 lb of calcined kaolin, 146 lb of in-place clay with a density of 95 lb/ft³ and containing 20 pct water must be mined. The 87.3 lb of final tailings in the dewatering column at the end of the 6 months averaged 46 pct solids and occupied 1.28 ft³.

Therefore, 100 lb of the kaolin tailings would occupy 1.47 ft³ as compared with 1.53 ft³ for 100 lb of mined clay. The tailings would have resulted from the production of 38 lb of alumina.

Martin found that the stabilization of storage pond surfaces increased with the use of sand beds and that drainage increased owing to capillary action caused by lowering of the water table and increased evaporation. The prolonged drainage period encountered in the 10-ft column of kaolin tailings was attributed to increased surface evaporation due to cracking. The cracking and increased drying contributed to the stability of the material.

Sand bed drainage of tailings improves drainage rates when top liquid decantation is employed. Prompt removal of entrained liquids increases volume consolidation rates.

Rapid drying hastens the onset of surface stabilization, allowing area reclamation. Collected drainage from lined ponds could be recycled and deter pollution.