Here is a list of the SAG Mill Manufacturers & Suppliers I know:

- FLSmidth

- Metso

- Outotec

- CITIC-Heavy Industries Co. Ltd

- Thyssenkrupp – Polysius

- Farnell-Thompson

- TyazhMash

- 911Metallurgy

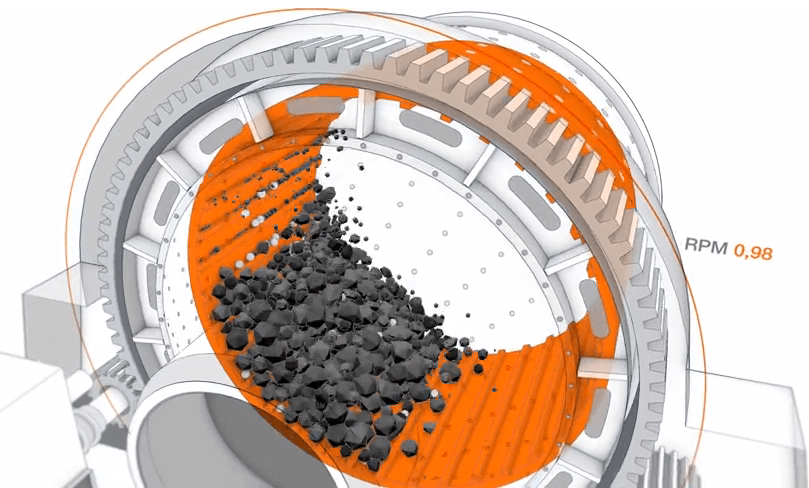

A highlight of SAG milling has been the collaboration between grinding mill manufacturers and mining companies. Experimental work on very large mills is difficult, expensive, and potentially catastrophic if it goes wrong, yet the work must be done if the mills are to be accepted for use. The results of the collaboration have been very successful, as can be seen by the large mills in use and the high treatment rates obtained at low cost per ton.

There are a number of SAG mills in operation around the world with diameters reaching up to 40 ft. These operations continually invest in new technologies to improve their energy efficiency and capacity in their SAG circuit. Commercial SAG mill performance is determined by a large number of variables, both mine-site variables and mill variables. In many cases these variables dictate production capacity seemingly randomly. Therefore, a number of operating philosophies, each specific to a plant, have arisen. In almost all concentrators, the SAG operation is continually evolving. Every year, ways and means are sought to increase capacity, decrease energy consumption, and prolong lifter and liner life. Ore blending, newer designs of lifters, recycle crushing, and redesign of grates and trommel screens are a few routes taken at considerable expense.