The lining of the rotary kiln is of the utmost importance, and great care should not only be exercised in selecting the class of brick, but to see that it is well fitted in the kiln in order that success may be achieved.

Fortunately, manufacturers are closely studying the question, and are now producing an excellent fire-brick equal to any that can be obtained abroad ; they are tackling the proposition in a scientific way, and continued improvement may be expected. But it must be borne in mind that all lining failures are not to be attributed to the bricks themselves. It may be due to lack of care in constructing and laying in the work. The bricks should be made to fit the radius of the kiln, and put in dry without fire-clay or cement. The last brick in the circle, being the key to the whole ring, should be well driven.

they are tackling the proposition in a scientific way, and continued improvement may be expected. But it must be borne in mind that all lining failures are not to be attributed to the bricks themselves. It may be due to lack of care in constructing and laying in the work. The bricks should be made to fit the radius of the kiln, and put in dry without fire-clay or cement. The last brick in the circle, being the key to the whole ring, should be well driven.

The whole ring should be afterwards grouted up with neat cement, the greatest care being taken to fill up all the interstices.

But even if the bricks are perfectly fitted to the kiln and of the best composition and suitable for the material to be burnt, if the rotary kiln has not been well designed to ensure absolute stability, especially at the roller bearing rings and girth gear, troupe will be always experienced at these positions with the lining. The shell should also be of sufficient thickness to prevent torsion, which also reduces the life of the lining.

Spalling (which is a popping-of of large pieces of the brick) occurs owing to the face of the bricks, becoming vitrified by the intense heat, being absorbed faster than they can conduct it to a cooler zone, and the elasticity of that portion is lost, and further heating or cooling taking place or movement in a kiln structurally weak, the vitrified section drops off, which otherwise would have been held by compression of the bricks themselves in a rigid kiln.

Assuming you have a strongly constructed kiln, lining blocks of correct composition and well fitted, and the question of fuel considered, there is no reason why a run of six months should not be obtained even where a highly siliceous material is being burnt and even nine months with aluminous material, whilst in the upper portions of the kiln it should’, with slight repairs, render efficient service for years.

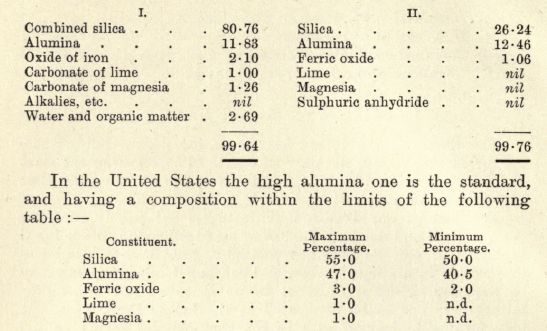

Most of the fire-bricks manufactured are of an acid character and high in silica, as the following analysis will show:

The operation of burning the clinker is a skilled process, and none but a capable and experienced hand should be employed as a burner. He must know exactly how the clinker should be burnt, and possess a keen eye for “ heat to enable him to know when the kilns are hot enough to properly clinker the raw material.

Coating a freshly lined kiln, and patching also, need a skill which is only acquired by much practice, and should in no circumstances be entrusted to a mere novice.

Though the rotary kiln has now firmly established itself as the most economical and efficient form of mechanism for the production of Portland Cement, many of the old stationary kilns, both of the intermittent and continuous varieties, are still in constant use in Europe ; nor is their product in any way inferior to that produced by the modern method. But to ensure this good clinker and reduce the quantity of under-burned material, the lumps of dry slip must be reduced to a uniform size of from 90 cubic inches to 100 cubic inches, and the coke must be no larger than a hen’s egg. Kilns charged with dry slip and coke of irregular sizes cool very slowly and remain for a longer period in the incandescent state, and the result is the clinker spontaneously crumbles to dust.

Though the rotary kiln has now firmly established itself as the most economical and efficient form of mechanism for the production of Portland Cement, many of the old stationary kilns, both of the intermittent and continuous varieties, are still in constant use in Europe ; nor is their product in any way inferior to that produced by the modern method. But to ensure this good clinker and reduce the quantity of under-burned material, the lumps of dry slip must be reduced to a uniform size of from 90 cubic inches to 100 cubic inches, and the coke must be no larger than a hen’s egg. Kilns charged with dry slip and coke of irregular sizes cool very slowly and remain for a longer period in the incandescent state, and the result is the clinker spontaneously crumbles to dust.

But increased competition in the cement trade is causing the manufacturer to put forth every endeavour to reduce the cost of production, and although at present many proprietors do not see their way to modernized their plants by the adoption of the rotary system, yet the day is not far distant when the stationary kiln, be it intermittent or continuous, will give place to the rotary kiln.

For the rotary kiln process not only produces a more regularly burnt clinker, but it is unquestionably more economical than the stationary kiln, having, as it does, the following advantages :

- A continuous running.

- An automatically regulated flow of raw materials to the kiln.

- Control of raw materials in their passage through the kiln. This is regulated by the revolution of the kiln, which may vary from one revolution in 2.5 minutes to one revolution in fifty or sixty seconds.

- Compete control of calcination.

- Reduced labour costs.

- A more uniform clinker with greater cementitious properties.

https://www.thermopedia.com/content/906/

https://babel.hathitrust.org/cgi/pt?id=uc2.ark:/13960/t7mp4wv4m;view=1up;seq=120;size=75