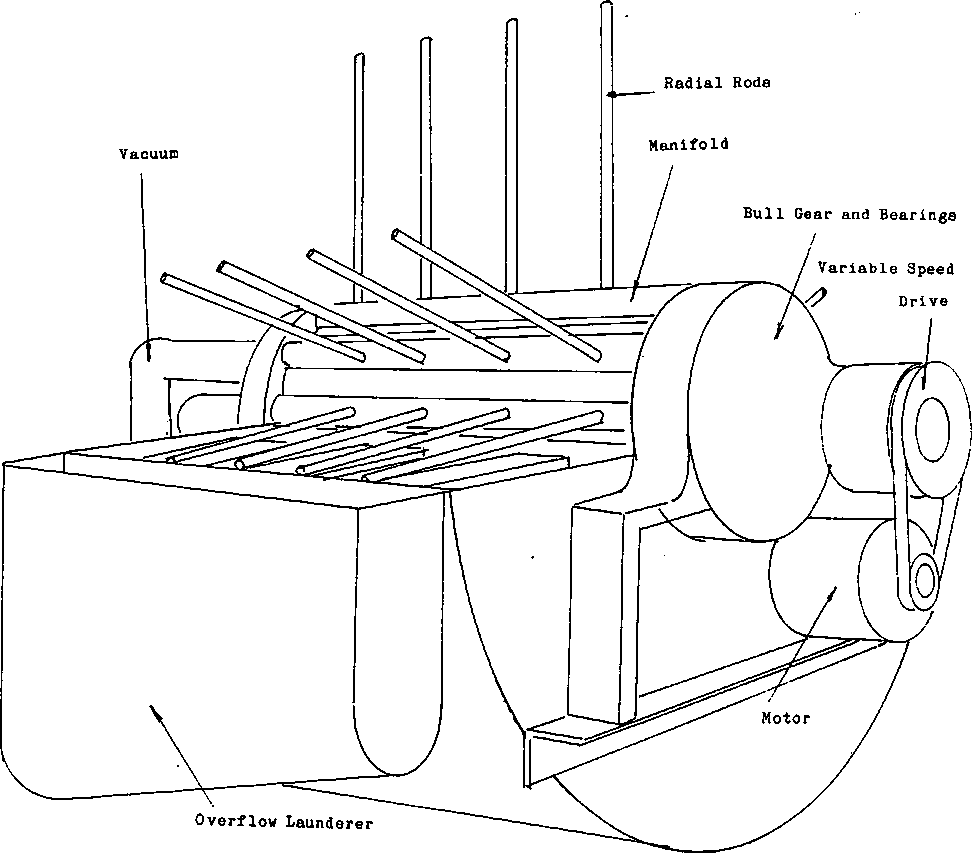

This insides (Internal Piping) of a Disk or Drum Rotary Filter and its Manifold are much similar to each other.

Each of the sectors are attached to what is known as the MANIFOLD. The purpose of the manifold is provide a series of passages for both the vacuum and the air. Each passage services one sector from each one of the discs that make up a filter. The sectors are attached to the manifold by RADIAL RODS. Each of these rods hold one edge of each of two sectors.

Each of the sectors are attached to what is known as the MANIFOLD. The purpose of the manifold is provide a series of passages for both the vacuum and the air. Each passage services one sector from each one of the discs that make up a filter. The sectors are attached to the manifold by RADIAL RODS. Each of these rods hold one edge of each of two sectors.

The timing in which the air and the vacuum is applied to the manifold is controlled by the FILTER HEAD. By revolving the head either clockwise or counter-clockwise, the position that the disc is at when the air is injected into the sectors, may be adjusted.

In this explanation of the components of the disc filter there are of course the TRUNNION BEARINGS, these support the filter, and the DRIVE LINE. This consists of a MOTOR, a VARIABLE SPEED GEAR REDUCER, PINION GEAR and BULL GEAR.

The bull gear assembly is attached to the trunnion bearing and takes advantage of that bearings lubrication system. Both are protected by a common casing.

The last two are the motor and the variable speed gear reducer. The purpose of the motor is self-evident. As for the gear reducer, the RPM of the disc is critical and because of this requires a method of speed control.

The object of the filter is to dry the feed as dry as possible and at the same time filter as much as possible.