Table of Contents

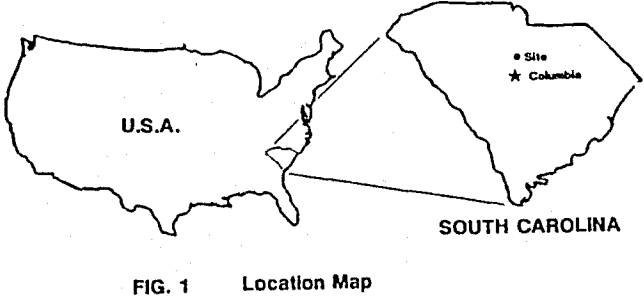

Kennecott Corporation, in joint venture with Galactic Resources Ltd., recently began operation of an open pit gold mining and milling facility near Columbia, South Carolina. The deposit consists of two ore bodies (North and South deposits) hosted in deformed and altered metavolcanics and metasediments of the Carolina Slate Belt. Emphasis includes the successful use of drill core orientation techniques to confirm complex geologic structure at depth; the development of a three-dimensional rock mass competency model, incorporating surface mapping data, results of bench mapping documentation, field index testing and laboratory testing; and kinematic assessments for design of optimum slopes.

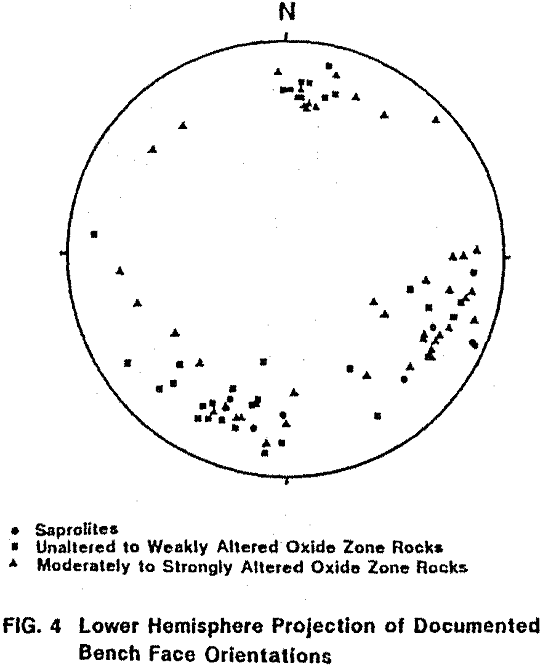

To determine the necessary geotechnical parameters and prepare optimum slope designs for both the operating and reclaimed walls of the South Pit, a detailed slope stability analysis and design study was undertaken in 1989. Field aspects of the study included: review of geologic plans and sections, geologic structural mapping of the initial pit walls, mechanical logging of existing drill core, and geotechnical mapping of all exposed benches.

Engineering Geology

The Ridgeway area lies within the Piedmont Physiographic Province of the southern Appalachians. The area is characterized by gently rolling topography with an average elevation of about 400 ft (120 m). The deposits are located in a northeast-southwest trending belt of deformed Precambrian to Paleozoic metavolcanic and metasedimentary rocks known as the Carolina Slate Belt. The Slate Belt, which extends some 600 miles (965 km) from Alabama to Virginia, contains numerous small inactive old gold mines and prospects.

The project area covers a major east-west trending contact zone between a metamorphosed sequence of submarine felsic to mafic volcanic rocks to the north, and metamorphosed clastic sediments to the south. The Ridgeway South deposit is hosted entirely by the Bear Creek turbidites, and is in close proximity to a fault contact with the younger Hidden Valley siltstone sequence to the south.

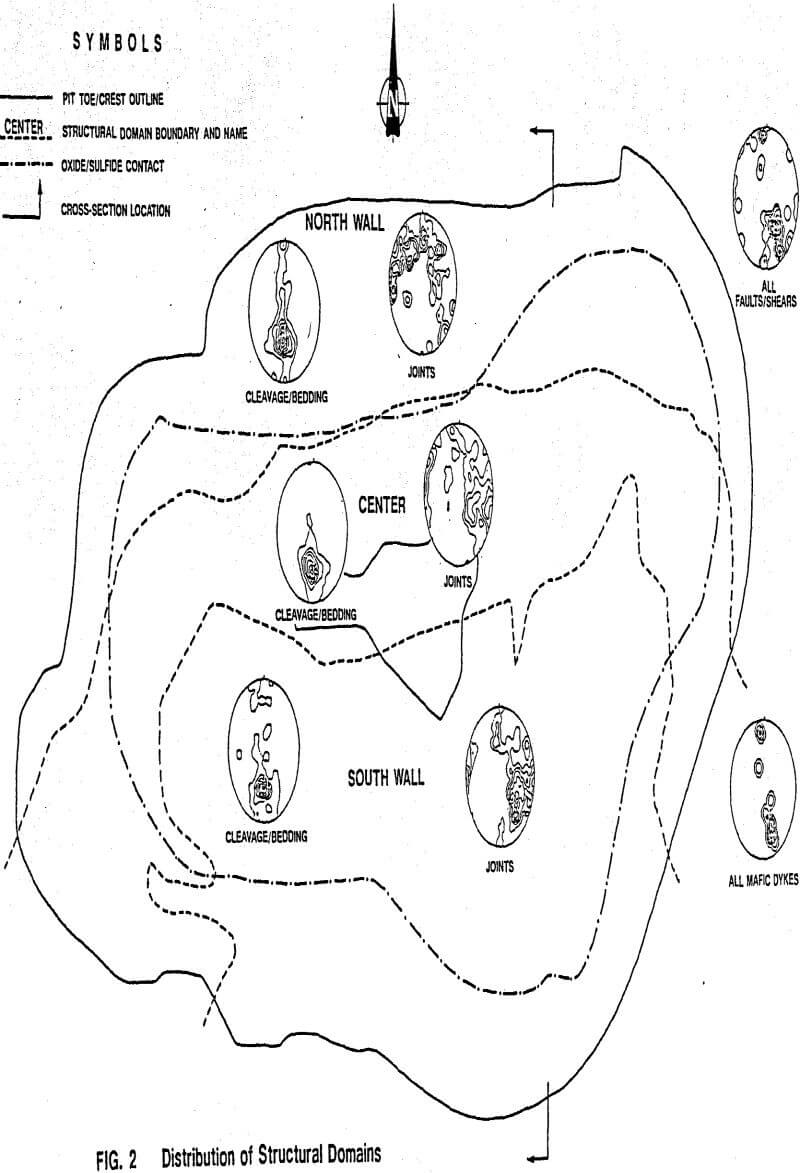

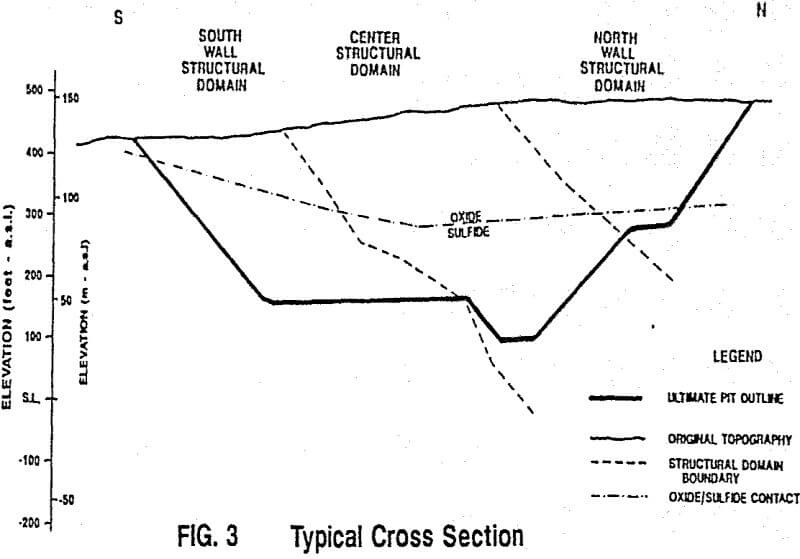

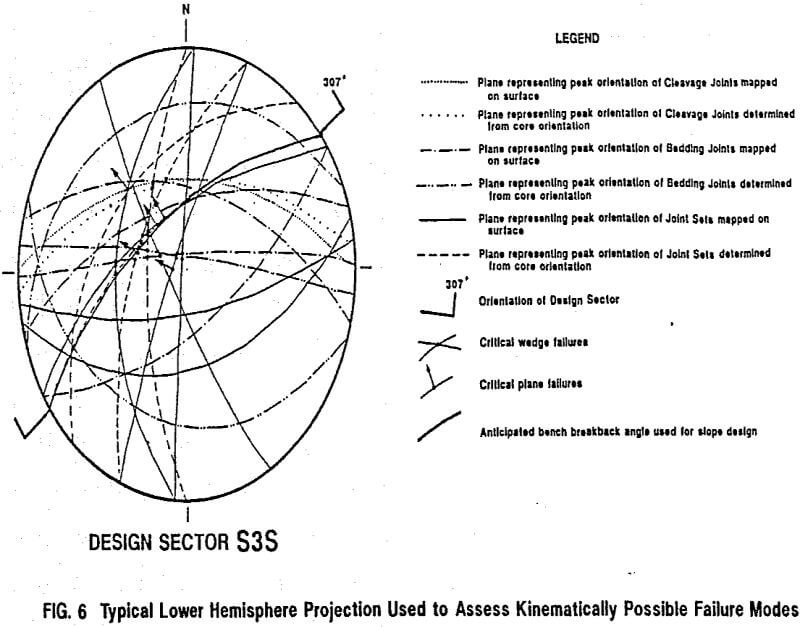

Slope stability analysis and pit slope design requires that the rock mass be subdivided into areas of similar geologic structural characteristics, called Structural Domains. For the South Pit, the rock mass was divided into three Structural Domains (i.e. North Wall, Center and South Wall Structural Domains), based on variations in the orientation of discontinuity populations observed on exposed benches and in core.

Faults and Dikes: Relatively few faults and dikes were observed on the open pit slopes. However, the majority of these structures are subparallel to Joint Set 3, with a few being parallel to Joint Sets 1 and 2. Most of the faults are continuous, with gouge and breccia infilling. In the drillholes, few faults were observed, but several mafic dikes were encountered.

In addition to assessments of the geologic structural characteristics of the rock mass, slope stability analysis and design requires quantitative assessments of rock strength parameters and their variability. Based primarily on the qualitative assessments of rock mass competency described above, the overall rock mass was divided into five basic rock mass units: Saprolite Zone, unaltered to weakly

altered Oxide Zone, moderately to strongly altered Oxide Zone, unaltered to weakly altered Sulfide Zone and moderately to strongly altered Sulfide Zone. Mechanical and strength characteristics are expected to be similar within each of these rock mass units.

Unconfined compressive strength (UCS) testing was conducted on core specimens from each rock mass unit, except for Saprolites, which were too soft for sampling using conventional coring techniques. Results indicate that within the Oxide and Sulfide Zones, UCS ranges from about 1000 to 3000 psi (7 MPa to 21 MPa), and 3000 to 10,000 psi (21 MPA to 69 MPa), respectively. In addition, moderately to strongly altered (i.e. silicified) rocks tend to be about twice as strong as unaltered to weakly altered rocks.

Hydrogeology

Based on regional groundwater monitoring prior to mining, the natural groundwater table in the vicinity of the South Pit appears to range from about elevation 375 ft to 450 ft (114 m to 137 m). In terms of assessing long term stability, it was projected that, following mining, the natural groundwater table would recover to approximately elevation 390 ft (119 m).

Monitoring of a series of water supply, dewatering and observation wells in the vicinity of the pit, indicates that a zone of depressurization has been created around the pit. Exposed slopes appear to be reasonably dry, and it was concluded that mining activities will continue to depressurize the rock mass immediately behind the bench faces. In terms of deep seated stability assessments, it was considered prudent to assume that only limited slope depressurization may occur in any given area of the pit.

Stability Analyses and Slope Design

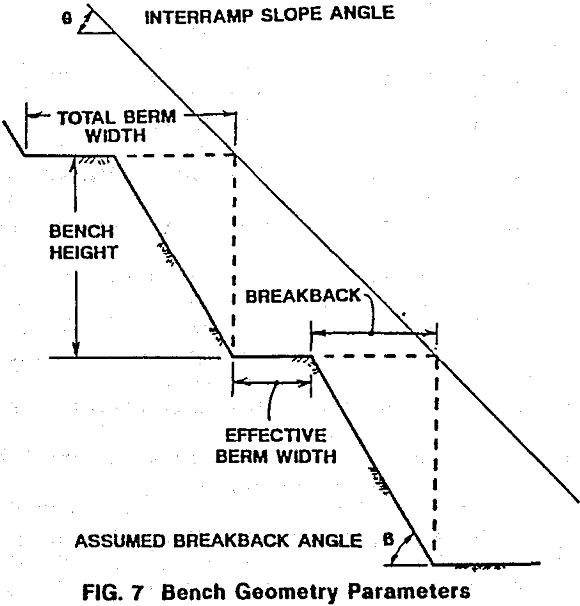

The main objective of most open pit slope design studies is to determine the steepest overall slope geometry which can be reasonably achieved, while maintaining adequate overall stability, and providing a safe working environment. It is usually impractical and/or not economic to design a slope such that no failures occur. In most cases, the optimum design is one which minimizes the risk of large scale instability, while limiting the size of individual failures so that they can be controlled and contained on the slope. Control of small failures is commonly effected through the use of benches, and in some cases, artificial support. This approach to design requires careful consideration of a wide variety of potential failure modes with respect to the geometry of the overall slope and the benches.

Stability analyses were carried out for each possible failure mode using limit equilibrium methods, and shear strength parameters determined from laboratory testing. Analyses were performed using dry or depressurized slopes, and all potential failure modes with a Factor of Safety of 1.2 or less were identified as critical failure modes.

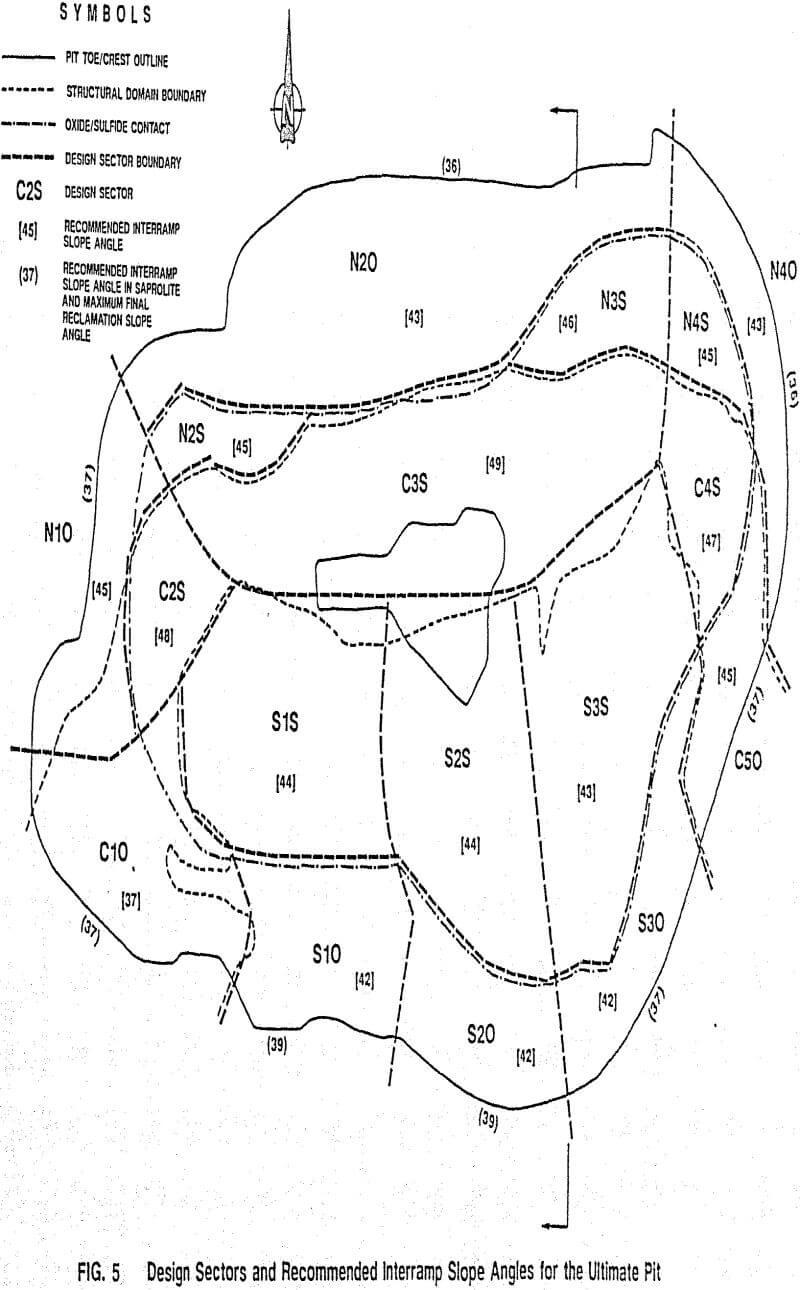

Recommended Slope Design

Recommended interramp slope angles for each design sector in the ultimate pit are illustrated in Figure 5. Single (i.e. 20 ft (6 m) high) benches were recommended for Design Sector C10, where rock mass competency is anticipated to be very low, and for all slopes in Saprolite. In all other design sectors, double (i.e. 40 ft (12 m) high) benches were recommended. Recommended interramp slope angles varied from 36° in Saprolites in Design Sectors N20 and N40, to 49° in Sulfide Zone rocks in Design Sector C3S.

Original pit designs and slope angles for assessing economics were based primarily on observed geologic structure. Detailed slope stability studies were completed about one year following startup. This scheduling proved advantageous and economic, as some initial benches had been exposed by the time geotechnical studies were underway, allowing a more comprehensive evaluation of geologic structure, rock mass conditions and slope behavior than would otherwise have been practical at the feasibility stage.