Table of Contents

The frictional resistance to motion of a belt conveyor has always been a subject of intensive studies and research by engineers throughout the years. Numerous informations have been developed by analysing series of field tests on belt conveyors of different characteristics and carrying different materials at various capacities.

Within certain limits of weight per unit length and tension, the theoretical considerations and the analysis of the field tests, both in the US and abroad, resulted in the development of similar formulas. In general these formulas are safe to use up to the following limits:

Tension average ≤ 7500 Kg

Weight per unit length ≤ 450 Kg/m

General

Primary resistances to motion of a belt conveyor are the frictional resistances of moving belt, components and load and the resistance at the belt line to lifting or lowering the load.

The work done in lifting or lowering a given load on a belt conveyor is an exact amount, whose computation is defined by physical laws; therefore the resistance to motion in lifting or lowering the load is directly proportional with the load and the power requirements can be easily calculated as follows:

HPlift = Constant x H x Q (hp)…………………………………………..(1)

H = lift (m)

Q = capacity (TPH)

Frictional resistances to motion, however are more of an impirical nature and a function of many factors, not always fully understood and difficult to express mathematically. Good results were nonetheless obtained from field measurements on conveyors with predetermined dimensions and loads, verifying within limits, results from formulas based on impirical values.

The coefficient of friction can be expressed in a formula consisting of the following components:

Where:

Ky1 = Coefficient of Imprint resistance

Ky2 = Coefficient of Belt flexing

Ky3 = Coefficient of Material flexing over idlers

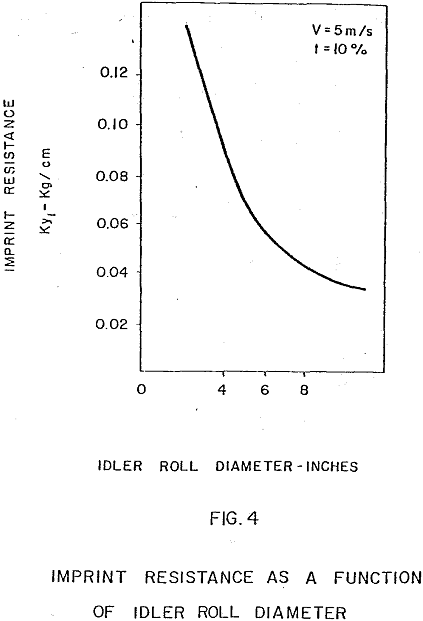

Frictional Resistance Due to Imprint (Ky1)

The phenomenon of the imprint of the belt on the idlers can be assumed to be similar with the phenomenon of the imprint of a wheel or roller on a flat surface when the surface is yielding. We know from experiments, although the coefficient of rolling resistance was assumed to be constant, that the resistance varies with the radius of the wheel, the weight of the wheel, the nature of the surface and the velocity.

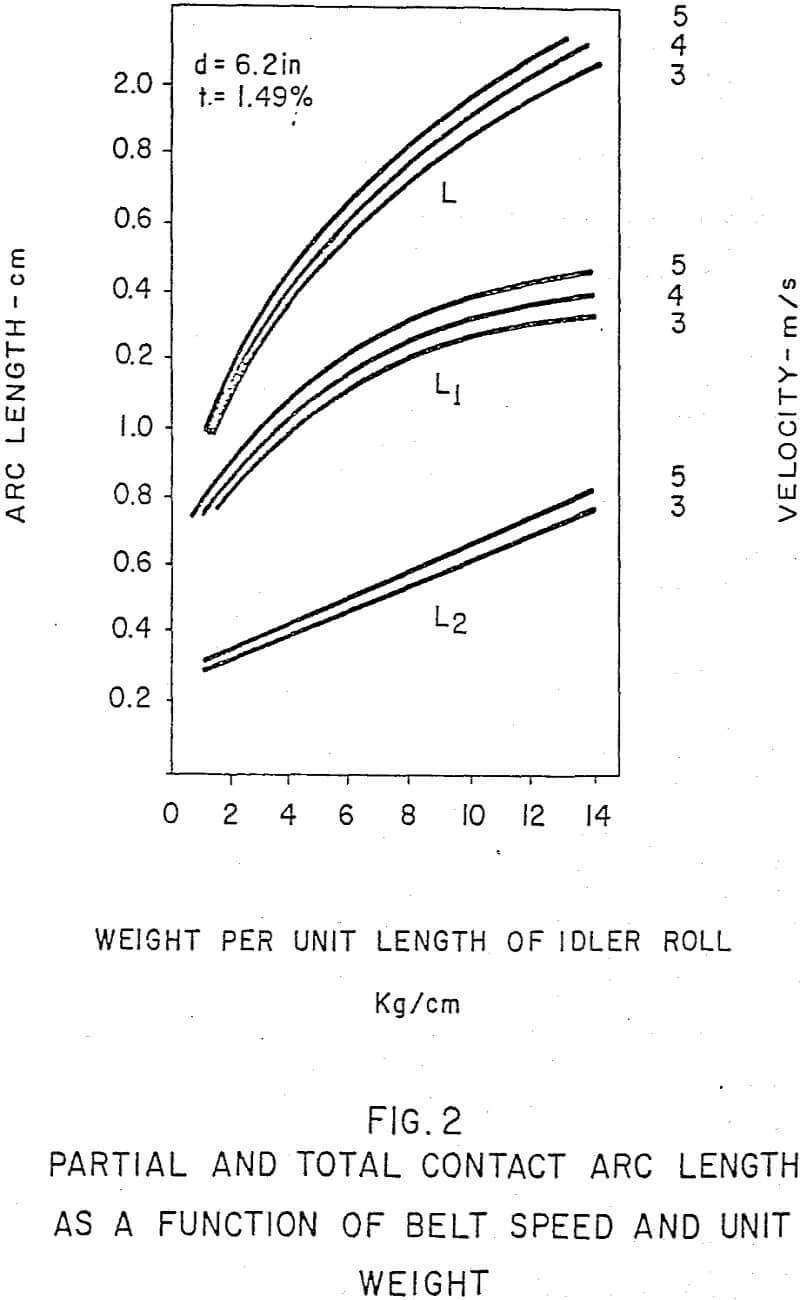

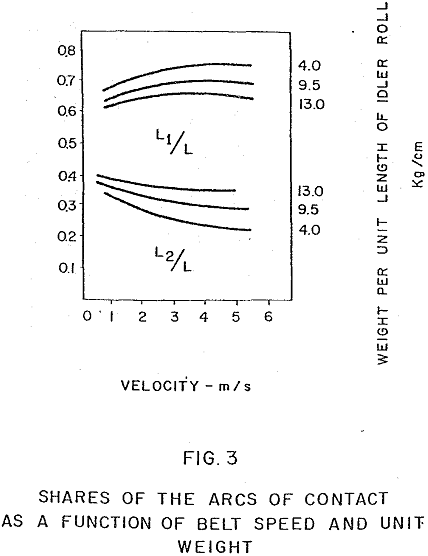

Comparing the imprint resistance on moving belts with the rolling resistance of a wheel and analysing experiments we find, that the imprint frictional resistance is a function of the following factors:

a) Weight of the material carried and of the belt per unit length (Wm + Wb);

b) Troughing angle, type, diameter of rolls and spacing of the idlers;

c) Type, thickness, cover hardness of the contacting cover and average belt tension of the conveyor belt;

d) Speed of the belt.

Belt and Material Flexing Resistance (Ky2 + Ky3)

The belt and material flexing between the idlers produce a resistance to motion; this resistance is a function of the: idler spacing, idler type, sag, weight of belt and material as well as the characteristics of the material.

Considering the phenomenon static and comparing the belt flexure with the flexure of an elastic beam on two supports, the resistance to flexure will be direct proportional with Hb³ and Hm³, where Hb and Hm are the vertical heights of the belt and material. These values vary depending on the type of idler and troughing angle.

Comparative dimensions for a 84″ conveyor based on layout and catalog information reveal that the material height (Hm) does not change appreciably from a 3 roll to a 4 roll idler. However, the belt height Hb for a 4 roll idler is approx. 5% lower than on a 3 roll idler. Therefore the resistance of the belt to flexing will be smaller for the 4 roll idler.

The frictional resistance “Ky” is made up of three components: IMPRINT, BELT FLEXING AND MATERIAL FLEXING RESISTANCE.

For a conveyor or a system with given characteristics the frictional resistance “Ky” can be expressed as a function of the weight per unit length and tension only. Therefore it varies throughout the length of the conveyor.

The frictional resistance formula can be expressed as follows:

Where:

Wm + Wb = kg/cm

Tave = Average tension in metric tons

a, a1, m, n = coefficients as indicated before