Table of Contents

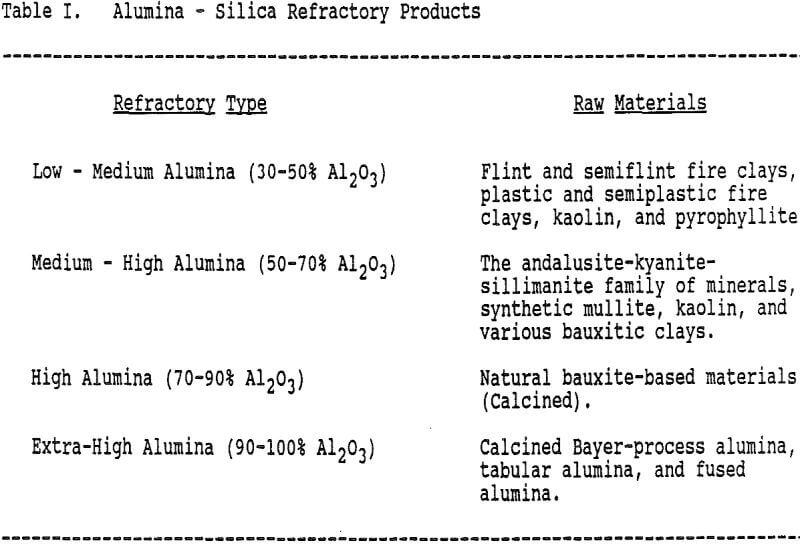

Refractories are commercial products created from nonmetallic minerals that possess the capacity to maintain their form and strength when subjected to highly elevated temperatures amid varying extremes of mechanical stress and chemical attack by hot gases, liquids, or molten and semi-molten substances. In the modern economies of the world, alumina (Al2O3), the oxide of aluminum, is the principal ingredient of a significant number of the products used in these high – temperature industrial applications. The alumina content of a particular refractory may range from 30% to 100%, depending on the nature of raw material employed to produce the refractory product.

General Specifications

The principal aluminum hydroxide minerals found in varying proportions within bauxite are: gibbsite, Al(OH)3; boehmite, AlOOH; and diaspore, AlOOH.

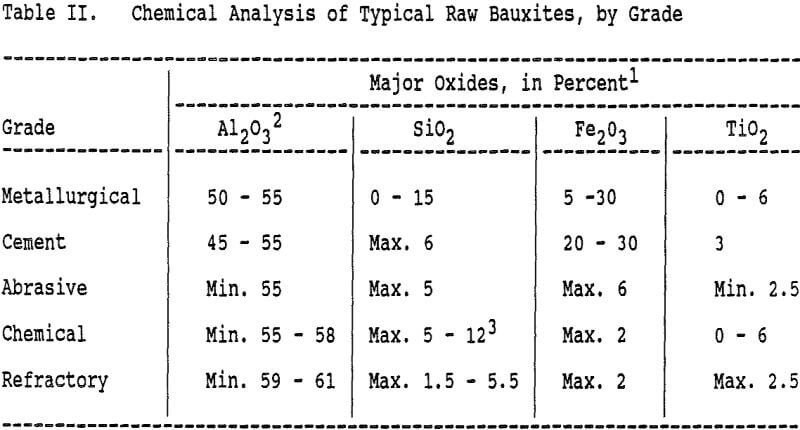

The bauxite used for producing abrasive, chemical, and refractory products must fulfill much more rigid compositional requirements than the crude ore that is commonly used for aluminum metal production, as shown in Table II. The natural chemical impurities that exist within these raw materials are not chemically removed from the ore during product processing, as in the case of metallurgical grade bauxite, where impurities are eliminated through a caustic leaching method that is known as the Bayer process. These specialty ores are utilized in an essentially unrefined form, as direct feedstocks for the production of their ultimate end products.

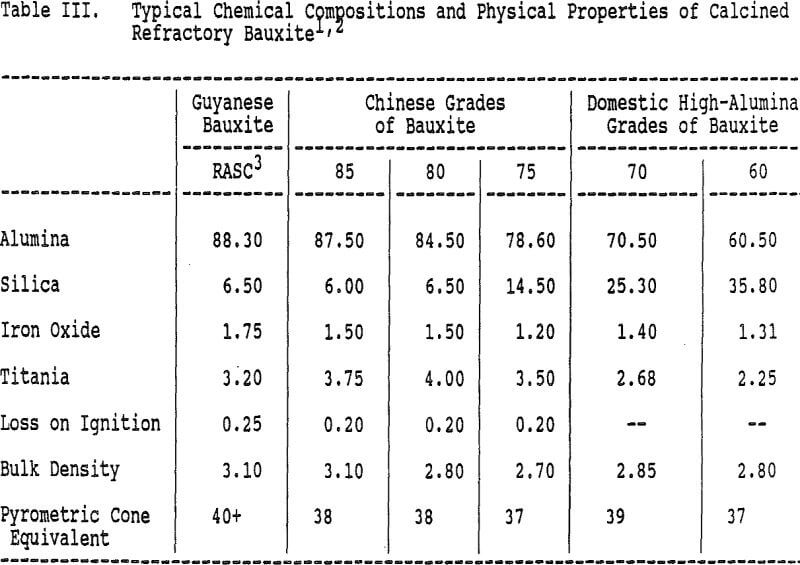

A number of tests are customarily applied to calcined bauxites to assess their suitability for use as a refractory raw material. Primary among these physical tests are: determination of pyrometric cone equivalent (PCE), a measure of the material’s softening or deformation temperature; measurement of bulk specific gravity; and calculation of apparent porosity.

Processing

The mining of crude refractory grade bauxite consists of the same methods and procedures that are customarily applied to the extraction of metallurgical grade bauxite ores. In fact, in some cases, special quality grades of bauxite are selectively mined simultaneously with associated metallurgical ore grade material.

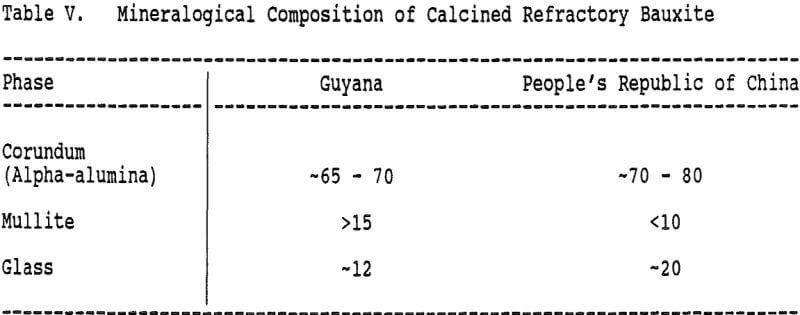

After crushing and screening to remove fines, and in some instances washing to physically remove clay and silica contaminants, the green or raw bauxite is usually fired at temperatures in the range of 1,400° C to 1,800° C in order to transform the material into corundum and mullite. This procedure is termed calcination and it is conventionally carried out in rotary or vertical kilns with the processed material undergoing very pronounced chemical and physical changes. During this intense heating process, all free moisture and chemically combined hydroxyl (OH) groups are driven from the bauxite. Normally in lump form at this stage, it requires crushing, grinding, and sizing before its final use as a refractory product.

Economic Considerations

The principal cost factors associated with the processing and production of calcined refractory grade bauxite are: acquisition of crude ore, labor wage rates, fuel charges, and transportation rates for the movement of the finished product to market. Due to the high energy requirements associated with the processing of these materials, the sensitivity of calcined materials to fuel costs is of primary concern in the development and continued viability of refractory operations.

Sources of Supply

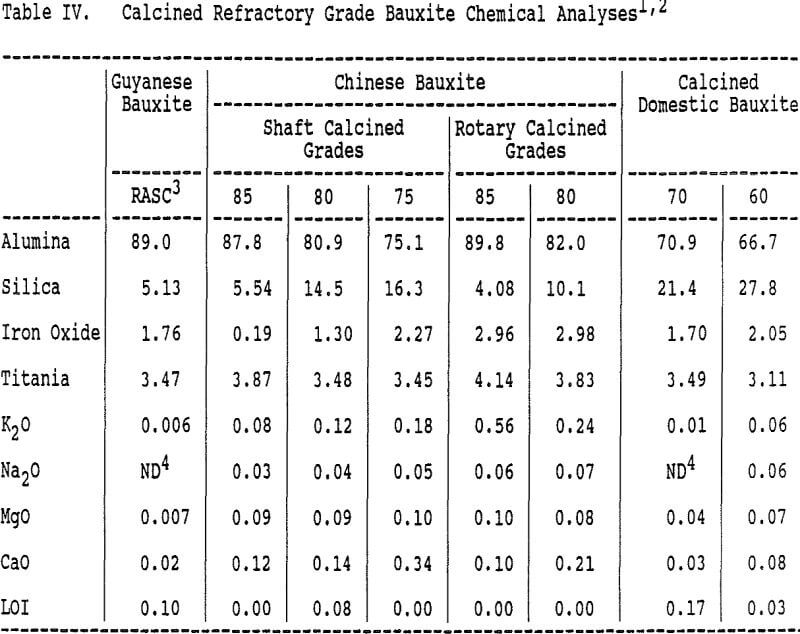

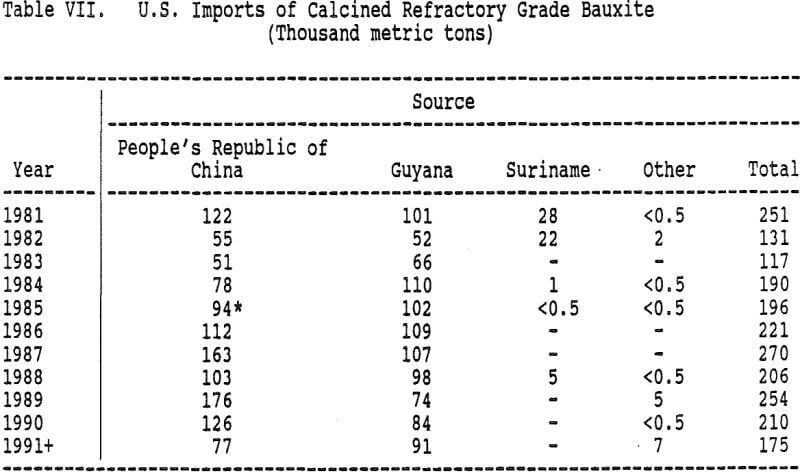

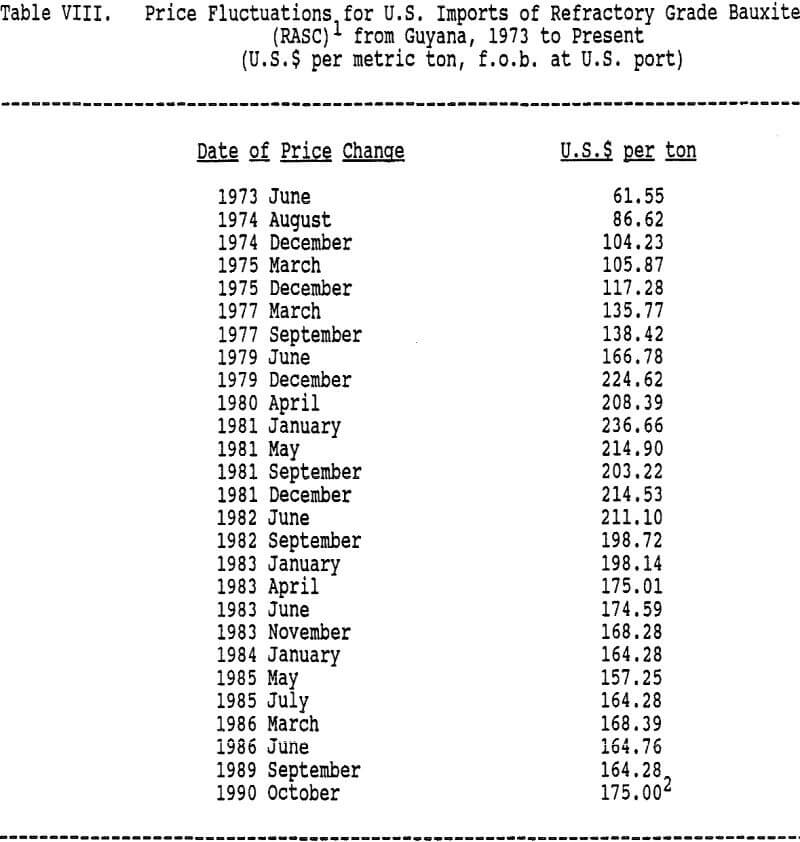

A limited range of naturally occurring bauxites have been found to meet the stringent physical and chemical specifications expected of refractory grade bauxite, particularly within the very high temperature fields encountered in most industrial applications. The highest quality materials have historically been supplied from South America, and in particular from mines in Guyana. As a result, because of its high quality, the RASC (Refractory A-Grade Super-Calcined) grade product from Guyana has frequently been used as a reference standard for the comparison with refractory calcined bauxites from alternative sources of supply. In fact, until the late 1970’s, refractory grade bauxite from Guyana satisfied approximately 80% of worldwide demand for this product. At that time, a combination of labor, technical, and mining difficulties within Guyana led to a severe market shortage which was alleviated by the expanded introduction of refractory raw materials from the People’s Republic of China into the North American and European markets. The new Brazilian producers are now beginning to test the international export markets with their refractory product and some of the material reportedly has been imported into the U.S. in recent years.

Currently, a major portion of the total bauxite ore mined in Guyana is exported for the production of smelter grade alumina. Recent calcined bauxite (RASC) output from Guyana has been rather erratic, the disruptions in productivity being primarily attributed to mine wall instability problems, which are related to the high overburden-to-ore ratios presently encountered within the Linden area mining operations, and serious kiln maintenance problems at Guymine’s calcining operations.

As indicated previously, coincident with the supply difficulties that developed within Guyana in the late 1970’s, the People’s Republic of China was able to gradually gain a major point of entry into the world’s refractory grade bauxite markets. The introduction of modern rotary-type calcining equipment has greatly improved the production situation and a total of eight modern rotary kilns, three in the southern province of Guizhou, one in the central province of Henan, and four in Shanxi within the northern portion of the country, are currently in operation.

Demand

Consumption of refractory grade bauxite within the market economies of the world is currently estimated to be between 700,000 and 800,000 metric tons per year and, combined with demand from the U.S.S.R. and the People’s Republic of China, total world consumption of bauxite for use in refractory applications is thought to be in excess of 1 million metric tons per year.

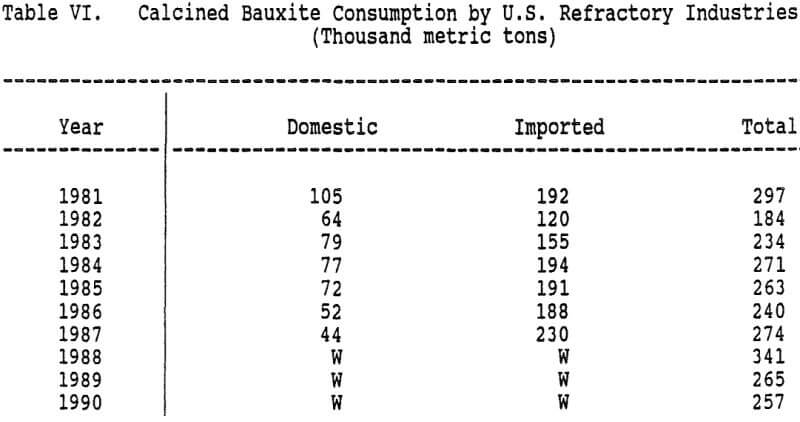

While the iron and steel industry remains the major market for refractory bauxite products, technological shifts over the last decade have resulted in the expanded use of higher performance specialty refractories, bringing about a marked decline in the consumption of refractories per ton of steel produced in the established steel producing countries of the world.

Outlook

The principal end uses of calcined refractory grade bauxite are directly related to the production and consumption of raw materials for basic heavy industry, such as primary metals, glass, cement, ceramics, etc. (Wright, 1990). This serves to make the demand for refractory grade bauxite very cyclical, as it is directly tied to the movements of heavy industry, the “smokestack” component of the national economy, a tie that is expected to continue well into the future.