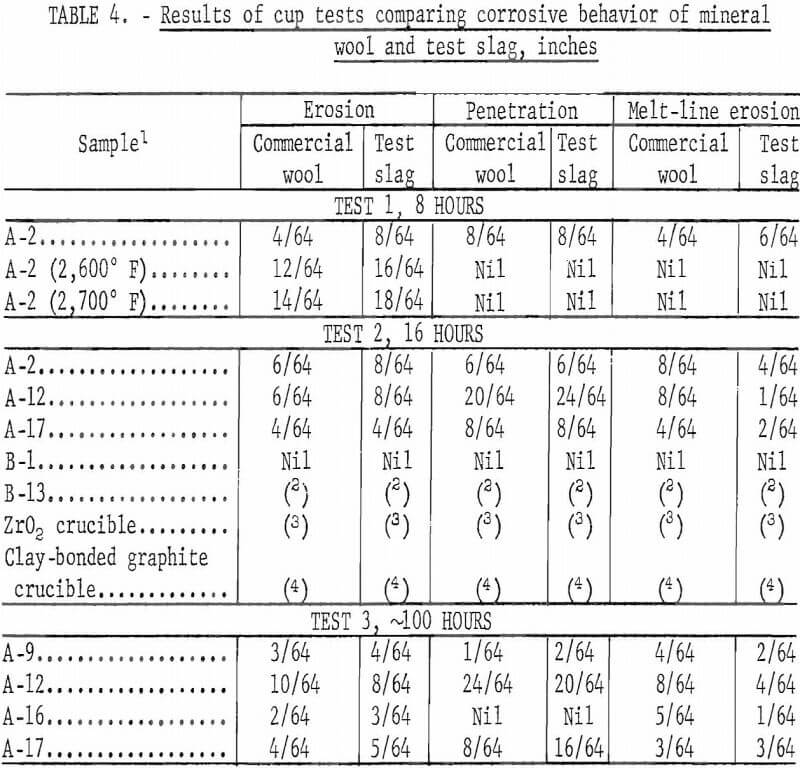

Table of Contents

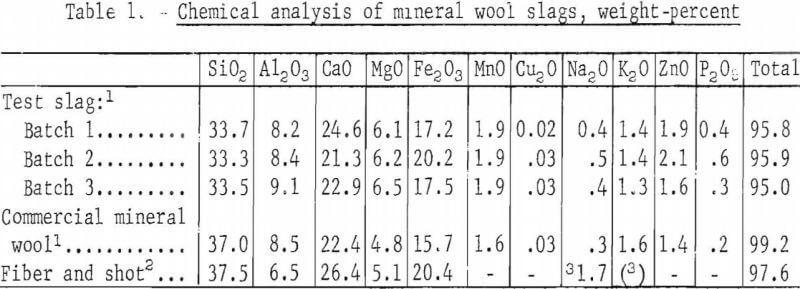

A slag formulation conforming to that used by a commercial mineral wool producer was used throughout testing. The composition of the test slag was as follows, in weight-percent: 9 copper-smelter slag, 41 lead-smelter slag, and 50 iron blast-furnace slag. Each component slag was crushed through 20 mesh, and a weighed amount of each was blended together. The batch thus formed was riffled into small lots from which test feed material was taken. In the course of testing, three batches were prepared. Their compositions are given in table 1. In tests comparing the behavior of the formulated test slag to mineral wool, commercial mineral wool was used. The composition of the commercial mineral wool is also given in table 1. Variations in chemical composition among the individual batches of formulated test slag and between the test slag and the mineral wool were minor. The data indicate that the composition of shot and fiber fines supplied by a manufacturer of mineral insulating wool was also in close agreement with the test-slag compositions.

Refractories

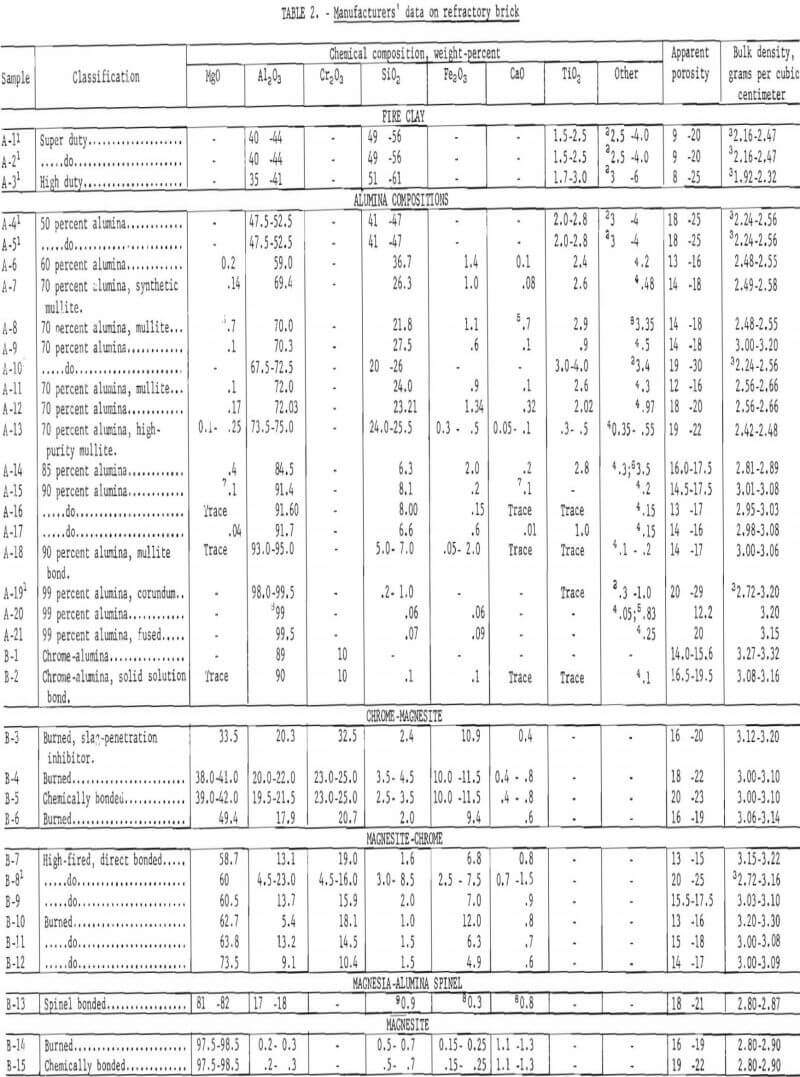

The refractories used in this investigation were obtained from six commercial producers. A total of 39 brands were tested: 21 alumina-silica, 2 alumina-chrome, 4 chrome-magnesite, 6 magnesite-chrome, 2 magnesite, 1 magnesia-alumina spinel, and 3 miscellaneous. Their refractory class, chemical analysis, apparent porosity, and density (obtained from the manufacturers data sheets) are given in table 2

Cup Tests

Description

For preliminary data on slag resistance, a static test was used. The static test procedure is commonly referred to as a “cup” slag test. Although this test is somewhat qualitative and does not allow for a thermal gradient in the refractories being tested, it has been used by many researchers in the past. The test is inexpensive, simple, and allows rapid collection of data for screening refractories. In the test procedure, full-size bricks were cut into blocks (3 by 3 by 3 inches or 3 by 3 by 2-½ inches). A 1-½-inch-diameter hole was bored in the top face by a diamond drill bit to a depth of 1-½ inches. The refractory was then dried at 250° F. In each test, 50 grams of the formulated test slag was placed in the recess. In tests involving commercial mineral wool, 50 grams of wool was compacted into a pellet 1-¼ inches in diameter by 1-¼ inches long and placed in the recess. An electric resistance furnace was used for all cup tests.

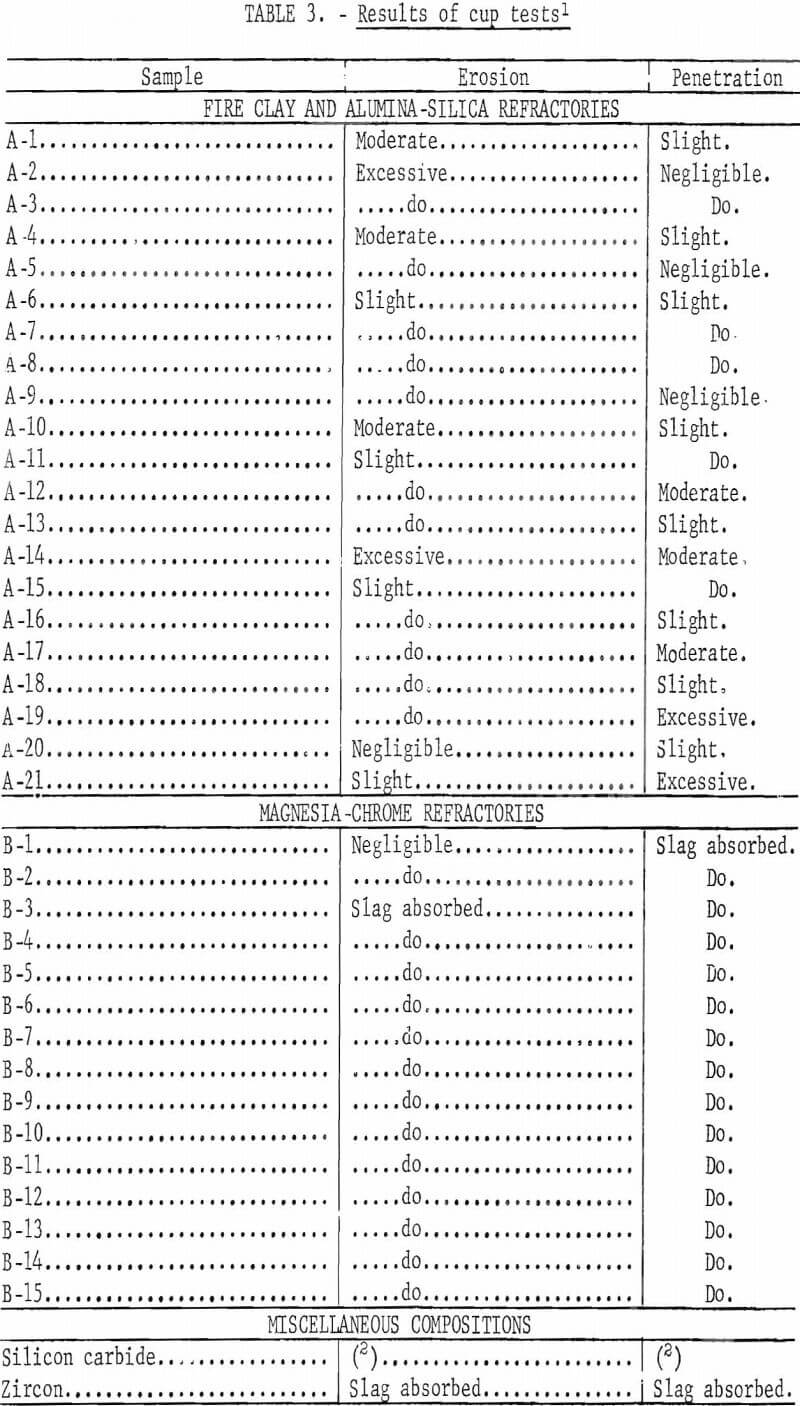

Test blocks containing the slag were heated from room temperature to 2,500° F in approximately 8 hours and soaked at that temperature for 23 hours. The refractory was then allowed to cool to room temperature in the furnace. A temperature of 2,500° F was adopted as the standard test temperature because it is approximately 100° C above the melting point of the slag. After cooling, the test blocks were sectioned through the center of the recess, and the erosion of the brick and penetration of the slag of the sectioned face was noted. The blocks were described as being negligibly, slightly, moderately, or excessively attacked by the slag- These determinations were made by visual observation; the results (table 3) were qualitative and were intended to screen out likely candidates for further testing

Discussion of Results

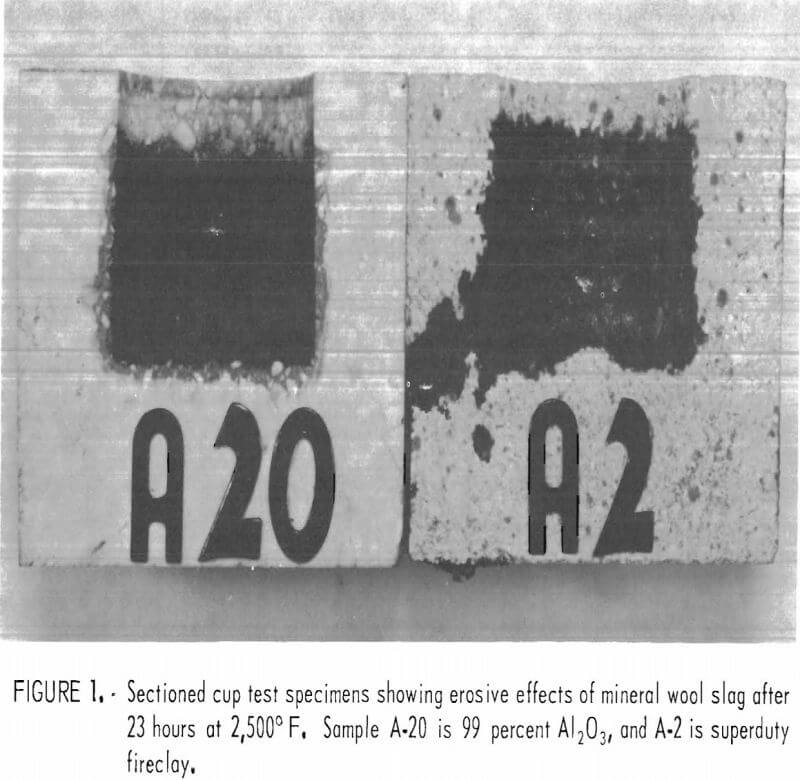

Superduty fire clay and low-alumina (<70 percent Al2O3) refractories were not suitable for use with the slag tested. Zircon brick, which are used in container glass tanks as “pavers” were also not suited for use with the slag tested. Zirconia, SiC, and clay-bonded graphite were likewise not resistant to the slag. In general, the results indicated that the higher the alumina content of alumina-silica refractories, the greater their resistance to attack. A typical example of this is shown in figure 1. Duplicate cup tests made on refractory A-2, a superduty fire clay, resulted in wall failures owing to reaction with the slag. By contrast, A-20, a 99-percent-alumina product, was almost inert to the action of the slag. However, the alumina content alone cannot be used to predict the resistance of a refractory to the slag because the chemical and physical environment is extremely complex. The cup test was of little value in evaluating magnesia-chrome refractories since they absorbed the entire slag charge, thus preventing assessment of the slag

resistance of the refractories. This difference in behavior apparently was not due to differences in porosity between magnesia-chrome and alumina-silica compositions. The range of the apparent porosities (based on manufacturers’ data) of alumina-silica refractories tested was as great as those of the magnesia chrome; apparent porosities were 12 to 22 percent and 13 to 23 percent for the alumina-silica and magnesia-chrome refractories, respectively. The magnesia-chrome refractories were later tested in a rotary test apparatus and were found not to be excessively porous to the slag. In contrast to the cup test, the rotary test allows for a thermal gradient in the refractories under test. The excessive porosity of magnesia-chrome refractories shown in these cup tests was attributed to the absence of a thermal gradient, which is a major shortcoming of the cup test.

Three tests comparing the corrosion behavior of the formulated slag with that of melted mineral wool were made to insure that the behavior of test slag would be similar to the behavior of the slag used in actual plant operation. The mineral wool was expected to be slightly less erosive when remelted than when initially melted, but similar enough to be used to gage the behavior of the formulated slag.

In the first test, refractory composition was held constant, and the temperature was allowed to vary. The refractory was chosen to give measurable erosion in a short time, The test slag and commercial mineral wool samples were heated for 4 hours at 2,500°, 2,600°, and 2,700° F in a fire clay refractory. As expected, both slag and mineral wool were more corrosive with increasing temperature. The slag was slightly more corrosive than the mineral wool at all the temperatures tested.

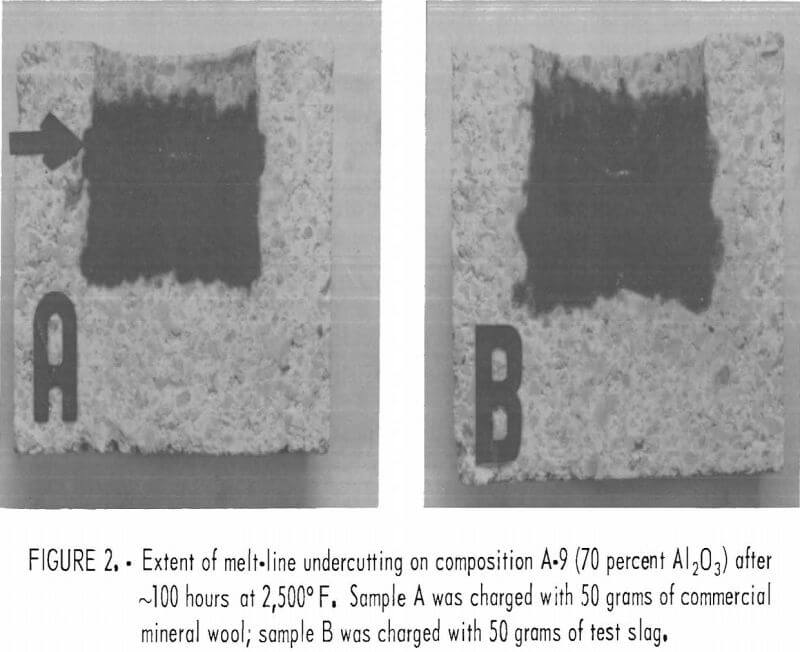

In the second test, the temperature was held constant and refractory composition was varied, but the test duration was extended to allow for more resistant compositions. Samples of slag and wool were heated for 16 hours at 2,500° F in refractories of fire clay, 70- and 90-percent alumina, clay-bonded graphite, magnesia-alumina, chrome-alumina, and zirconia. The chrome-alumina (B-1) demonstrated superior resistance to attack by both slag and wool. The magnesia-alumina (B-13) was porous to both slag and wool; no conclusions as to its resistance to erosion or reaction with either slag or wool were drawn. Reaction with slag and wool was noted with both ZrO2 and clay-bonded graphite crucibles to the extent that both compositions were thought to be unsuitable for further testing. For all other compositions, the formulated slag was more corrosive, but the melted mineral wool undercut the refractory wall at the melt line. An example of undercutting is presented in figure 2.

The third test compared the corrosive behavior of slag and wool after extended heating (100 hours) at 2,500° F on two 70- and two 90-percent-alumina refractories. The 90-percent-alumina compositions were more resistant to corrosion by both slag and wool than the 70-percent-alumina compositions. Melt-line undercutting was more pronounced for all cavities containing melted mineral wool. The formulated slag was only slightly more corrosive than the wool. The extent of erosion and corrosion on test samples used in the three tests is shown in table 4.

In these three tests, the degree of difference between the behavior of slag and wool was small, but it consistently indicated that the slag was slightly more corrosive. Therefore, test results based on the action of slag should be representative of results obtained with plant feed. These test results also are consistent with the trend noted previously; that is, that resistance to mineral wool slag formulations increases with increasing alumina content in alumina-silica refractories.

Rotary Tests

Description

The shortcomings of cup tests, the lack of a thermal gradient and. their general qualitative nature, required another test procedure to insure a better evaluation of the resistance of refractories to corrosion and erosion by the slag. The rotary test is more severe in its action on refractories during testing in that chemical equilibrium between refractory and slag is less likely to be approached. The rotary test also lends itself to quantitative techniques more readily than the cup test.

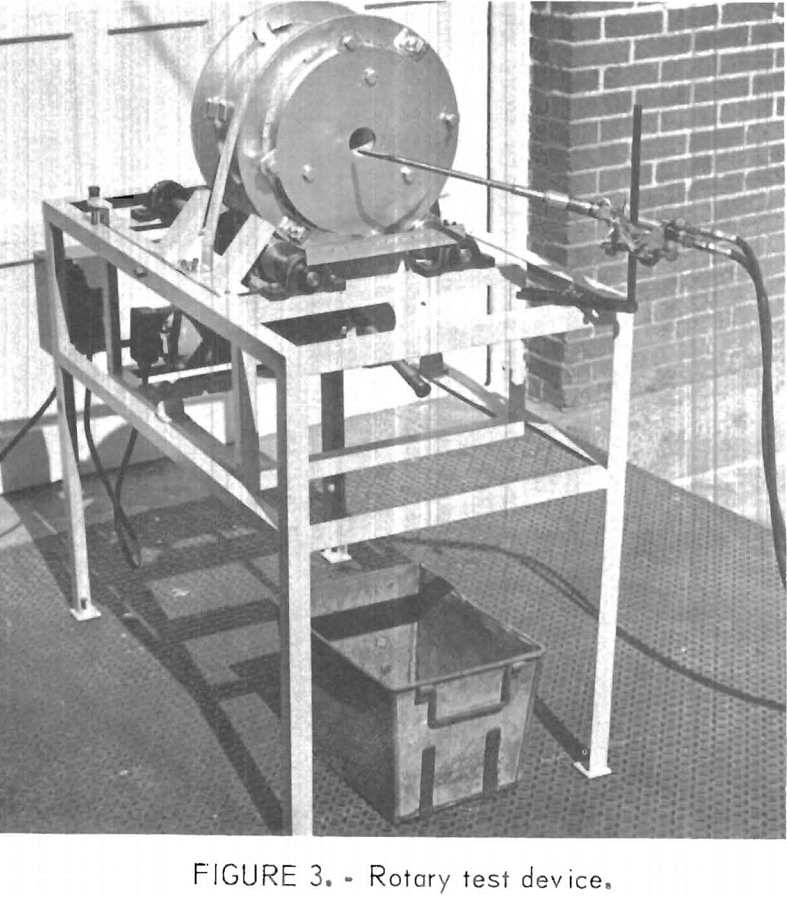

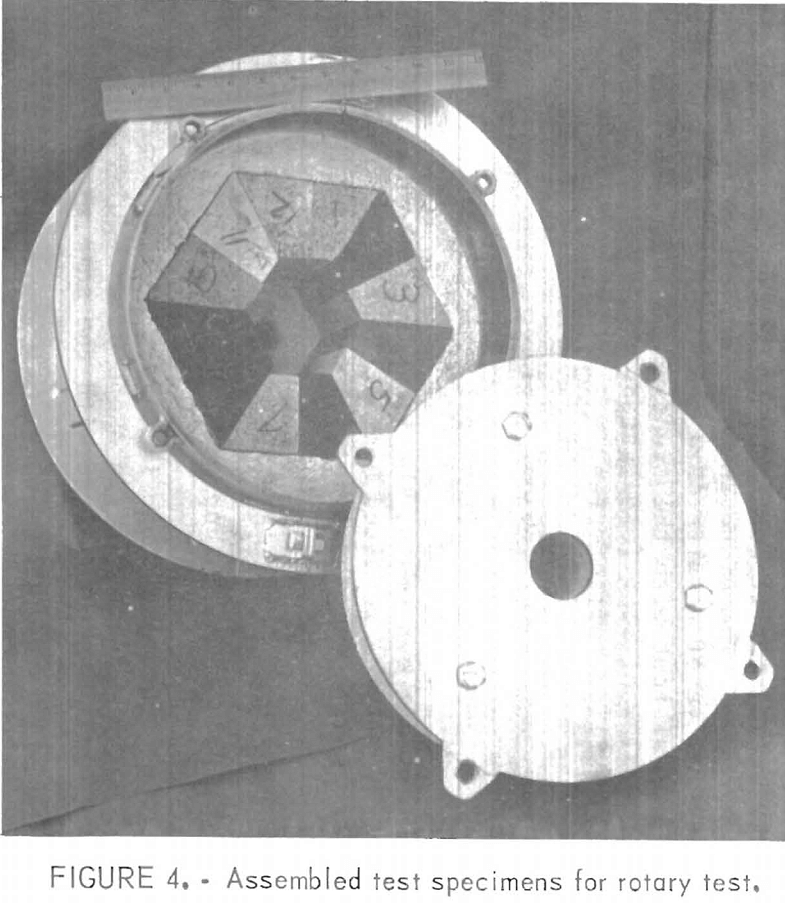

The rotary test device is shown in figure 3. The steel drum had a 94- percent-alumina castable lining in the shape of a regular hexagon and was fitted with removable end plates lined with the same material. Twelve test specimens were placed into this cavity (fig. 4) . The specimens were cut from 9-inch straight (9- by 4-½- by 2-½-inch) refractory brick in such a manner as to retain an unaltered surface as the test hot face. This hot face was roughly 1-3/8 by 4-½ inches; the corresponding cold face was 2-5/8 by 4-½ inches. The blocks were 2-½ inches thick. In the test procedure developed, the drum was lined with test brick and rotated by a variable speed drive unit at 8 rpm, which is equivalent to a peripheral speed of 10 fpm. at the slag-refractory interface. The molten slag inside was heated by an oxyacetylene torch to 2,825°±35° F.

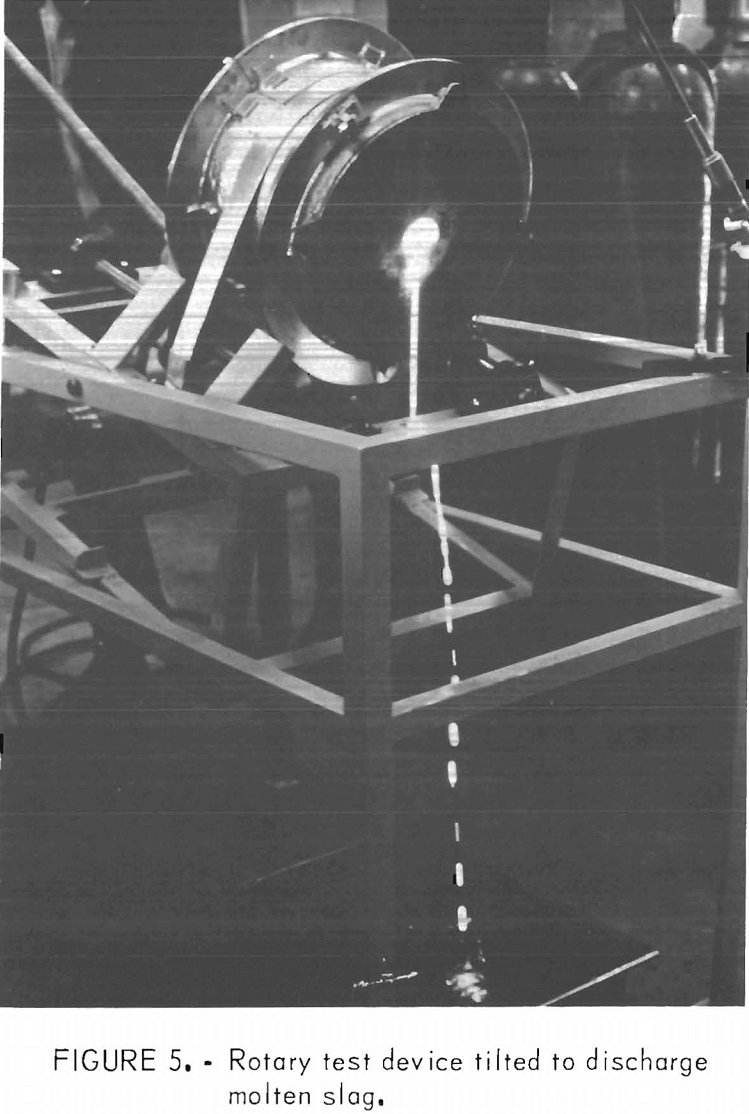

The tests were run in a cyclic manner as follows. The drive unit was started, the torch ignited, and the drum heated to test temperature. The torch was then moved aside, and four 100-gram slag pellets were charged into the rotating drum through a 2-inch-diameter hole in the front plate. The torch was repositioned, and the apparatus was brought back to temperature and held for 20 minutes. The torch was then moved aside, the drive unit stopped, the drum locked on the driving flanges, and the drum-and-drive unit tilted to discharge the slag as shown in figure 5. The procedure was repeated until the desired number of cycles was achieved. The feed used for the rotary tests was the same formulated test slag used in the cup tests. The slag was pelletized, using a commercial ligno-sulfonate binder, to reduce loss of feed that could result from charging a powder.

Discussion of Results

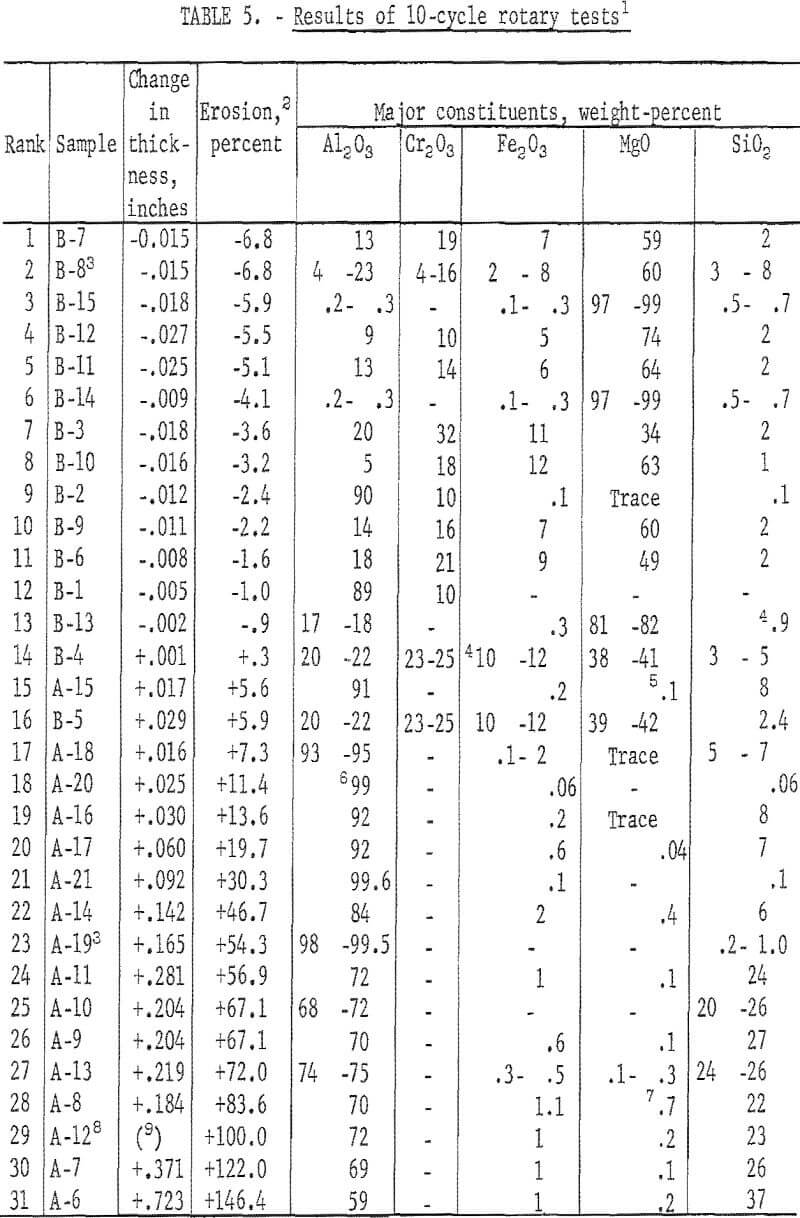

Thirty-one refractory compositions were tested using the rotary test device in three 10-cycle test runs. In the first run, 11 samples were tested; one sample (A-12) was run in duplicate. This composition was designated as a standard and used in all subsequent runs to provide a basis for comparison among runs.

Prior to lining the rotary drum; the thickness of each test specimen (the distance between the hot and cold faces) was measured with a micrometer at three points on their long dimension. After testing, the specimens were again measured at these points. The difference before and after testing of each point was calculated, and the average change in thickness of the three points for any given composition was then compared to the average dimension change of the standard in that run. This average change was expressed as a percentage of the standard’s erosion, which was taken as 100. In this manner, all compositions were ranked (table 5).

Many of the specimens exhibited an increase in thickness after testing. This was because the combined thickness of reaction products forming near the slag-refractory interface and the residual slag layer on the refractory was greater than the erosion. Prolonged testing should result in erosion of such magnitude as to effect an overall decrease in specimen thickness. Of the 15 least eroded compositions, 13 were of the magnesia-chrome type. The ninth-ranked composition, B-2, was a 90-percent alumina, 10-percent chromic oxide composition. The only alumina-silica refractory among the 15 best compositions, but the least resistant of this group, was A-15, a 90-percent-alumina brick.

Although the superiority of magnesia-chrome compositions (B-3 through B-15) to alumina-silica compositions (A-6 through A-20) in resistance to mineral wool slags was clear, some weaknesses in the testing method require discussion.

In this cyclic test, the slag was periodically discharged from the rotary drum by tilting. This required removal of the torch. After discharging, fresh slag was added, the torch was repositioned and heating was continued. The slag was melted, and the drum and slag brought to test temperature; at this point, timing of the cycle was initiated. The overall testing time for runs 1, 2, and 3 were 350 minutes, 315 minutes, and 313 minutes, respectively. The runs were of ten 20-minute cycles for a total of 200 “timed” test minutes. The additional 100+ minutes during which slag was in contact with refractories was not reflected in the stated testing conditions. Average test temperatures, based on optical pyrometer readings taken at 5-minute intervals, were 2,790° F, 2,800° F, and 2,860° F for runs 1, 2, and 3, respectively.

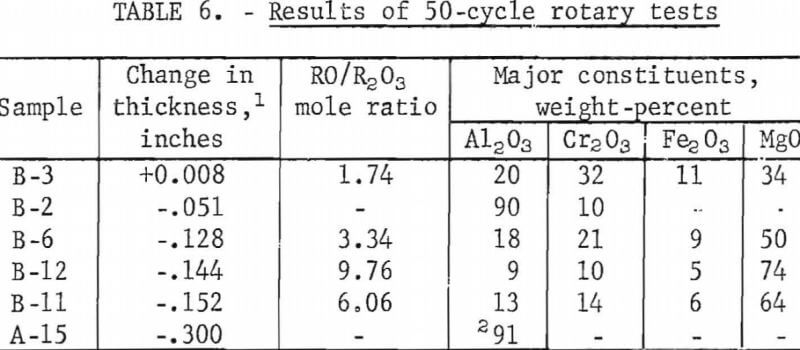

With these considerations in mind, a 50-cycle rotary slag test was run with duplicate samples of six refractories from the 10-cycle test to exaggerate the small performance differences previously demonstrated. The average temperature for this test was 2,850° F. Refractory A-15 was chosen because it was the best of the alumina-silica series of compositions tested. Refractory B-2, a 90-percent alumina, 10-percent chromic oxide product, was included because of the superior performance it and a very similar composition (B-1) had shown; both are very different chemically from the highly resistant magnesia-chrome compositions. The four remaining refractories tested represented a series of magnesia-chrome compositions with the MgO varying as follows: 33.5-percent MgO (B-3), 49.4-percent MgO (B-6), 63.8-percent MgO (B-11), and 73.5-percent MgO (B-12). The results of the 50-cycle rotary slag tests are summarized in table 6. Refractory B-3 was shown to be superior to the other compositions and exhibited an increase in thickness after 50 cycles of testing. The compositions that showed increases in thickness after 10 cycles of testing (B-2, B-6, B-11, and B-12) were significantly eroded after 50 cycles.

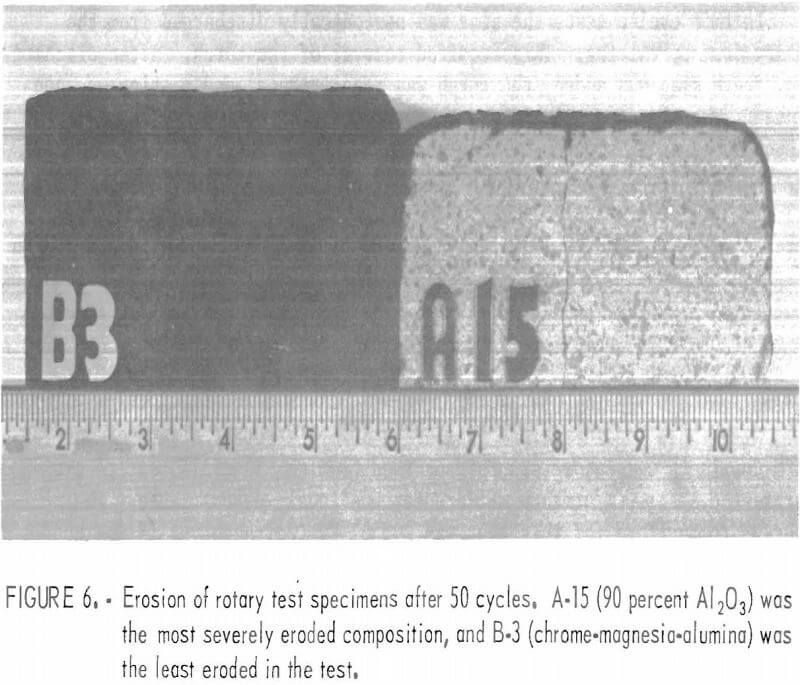

Where applicable, RO/R2O3 mole ratios were calculated for the test compositions. In general, these data indicate that the higher the RO/R2O3 ratio, the greater the extent of erosion for magnesia-chrome refractories. Refractory A-15 (90-percent Al2O3), the only alumina-silica refractory thought resistant enough for extended testing, was the most severely eroded of the 50-cycle test compositions (fig. 6). Refractory (90-percent Al2O3; 10-percent Cr2O3) was second only to B-3 in erosion resistance.

Conclusions

Results of the cup tests and rotary tests show that alumina-silica refractories are eroded by mineral wool slags. In general, the rate of erosion increases as the temperature is increased, and decreases with an increase in the alumina content of these refractories. Owing to high erosion rates, low-alumina (<70 percent Al2O3) refractories of the silica-alumina series are not suitable for service as a furnace lining for melting mineral wool slags at a temperature of 2,500° F. The following refractory compositions are also unsuitable: zirconia, zircon, clay-bonded graphite, and silicate-bonded silicon carbide.

High-alumina (>70 percent Al2O3) refractory brick will give limited service (>2,500° F) in mineral wool furnaces at high costs, due to high erosion rates and high initial costs. Special alumina-chrome (90-percent Al2O3, 10-percent Cr2O3) compositions will give longer service life at higher temperatures (2,825° F), but these are premium-priced refractories.

Refractories with magnesia and chrome oxide as major constituents are superior to alumina-silica refractories for use in lining electric furnaces for melting mineral wool. The data indicates low to moderate erosion rates for a broad range of magnesia-chrome combinations. These data also indicate an increase in erosion resistance as the mole ratio of RO to R2O3 decreases. Magnesia chrome refractories are also relatively inexpensive, generally costing less than one-half as much as high-alumina compositions.

Recommendations

There is a great need for additional work in the area of slag testing of refractories. In particular, the development of a reproducible rotary test should have high priority. Major problem areas in rotary slag testing revealed in this study include temperature control, temperature measurement, and the cyclic test mode. It is recommended that a magnesite-chrome composition similar to sample B-3 be used as the lining material for small-scale evaluation tests in an arc furnace. It is further recommended that additional work be done on the development of a reproducible rotary test to facilitate selection of the best suited refractories in a variety of refractory-slag systems.