Table of Contents

- Materials Equipment and Procedure

- Results and Discussion

- Preliminary Carbon Adsorption Studies

- Solvent Extraction Studies on As-Received Elox Solution

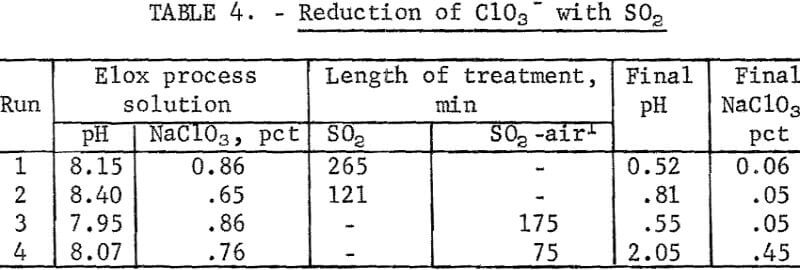

- Reduction of ClO3- With SO2

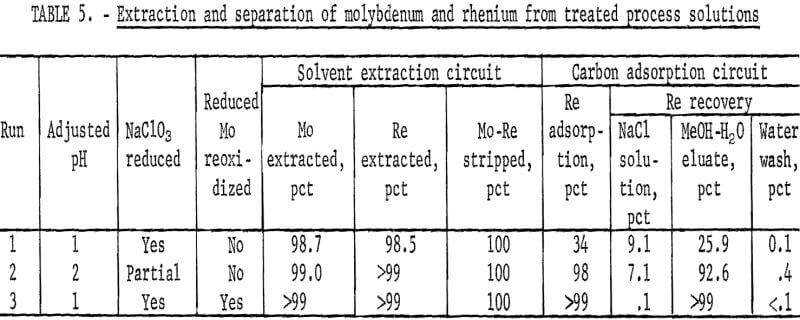

- Molybdenum and Rhenium Extraction and Separation From Treated Process Solutions

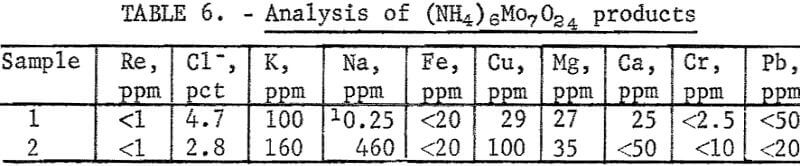

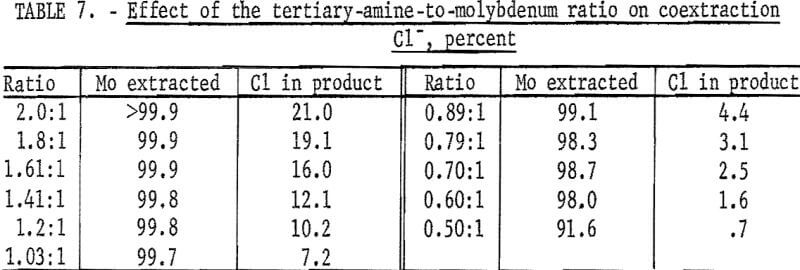

- Recovery of (NH4)6Mo7O24 From Column Effluent

- Recovery of NH4ReO4 From MeOH-H2O Eluate

- Recovery of Sulfate From the Solvent Extraction Raffinate

- Precious Metal Adsorption on Activated Carbon

- Conclusions

Projections for the expanded use of rhenium as a catalyst in the catalytic reforming of gasoline stocks to make low-lead gasoline prompted the Federal Bureau of Mines to investigate techniques for rhenium and molybdenum separation and recovery. In current technology, rhenium is recovered from the roaster gases produced during the oxidation of molybdenite concentrates. The gases are scrubbed and the dilute rhenium solution passed through a strong base resin to adsorb the rhenium. Elution is accomplished with NH4SCN; the NH4ReO4 is recovered by selective precipitation.

The Bureau of Mines has developed a hydrometallurgical technique for processing molybdenite ores and concentrates because current industrial technology results in low recovery of molybdenum and rhenium. Briefly, the process uses a brine slurry of molybdenite ore or concentrate in which electrolytically generated hypocholorite (OCl-) oxidizes and solubilizes the molybdenum and rhenium. If they are present in the ore or concentrate, gold and silver are also solubilized. The sulfide ion is oxidized to sulfate and solubilized.

Separation of molybdenum and rhenium in an aqueous solution has been demonstrated previously. Fisher and Melache absorbed molybdenum and rhenium from a 1-M NaOH solution with a strong base anion-exchange resin. Molybdenum, was eluted with a 2.5-M NaOH solution, after which rhenium was eluted with a 7-M HCl solution. The method was improved by Melache and Preuss, who eluted molybdenum with a 1-M potassium oxalate (K2C2O4) solution and rhenium with a 1-M perchloric acid (HClO4) solution. Hamaguchi used a thiocyanate-chloride (SCU-Cl-) solution to elute rhenium from a strong base resin, followed by a 2.5-M ammonium nitrate (NH4NO3) solution to elute molybdenum. Zimmerly and Prater used a NaOH solution and a HClO4 solution to elute molybdenum and rhenium, respectively, from a strong base resin. A quaternary amine was used for extraction of rhenium from an aqueous solution by Churchward and Rosenbaum. Rhenium was stripped from the organic phase with a HClO4 solution and recovered by electrolytic deposition. This method was also used to extract molybdenum, but not to separate molybdenum from rhenium.

Lee, Reynolds, and Bhappu studied the adsorption of molybdenum and rhenium on activated carbon. They found that above pH 6, Mo(VI) was not adsorbed, but Re(VII) was. They suggested a processing sequence involving coadsorption of molybdenum and rhenium on activated carbon at pH 2, elution of molybdenum at pH 6 to 9 with an unspecified buffer, and subsequent elution of rhenium with a 0.5- to 1.0-M HClO4 solution.

The objective of the present investigation was to develop an economic technique for separating molybdenum-rhenium in an aqueous solution whereby the reagents are recycled and high-purity products are obtained. Emphasis was placed on the use of feed solutions derived by the electrooxidation of sulfide minerals.

Materials Equipment and Procedure

Feed solutions used in this study were obtained from a metallurgical circuit in which molybdenite concentrates were oxidized electrolytically in a brine slurry. This process results in the formation of soluble molybdate, perrhenate, hypochlorite, chlorate, and sulfate species. The solutions from the electrooxidation (Elox) circuit contained about 1 to 50 ppm Re, 10 pct NaCl, and in grams per liter, about 2 to 10 Mo, 20 to 40 SO4=, 4 to 10 ClO3- and 0.1 to 0.5 OCl-. The pH of the solutions ranged from 8 to 9.

Two organic extractants were investigated: a commercially available quaternary amine, and a commercially available tertiary amine. These extractants were dissolved in a commercially available petroleum distillate. Isodecanol was added to the quaternary amine system as a phase conditioner.

The feed solution and organic phase were placed into a separatory funnel, which was shaken for 1 min. After the phases disengaged, the aqueous phase (raffinate) was withdrawn, and a stripping solution was added. The separatory funnel was shaken again, and the phases were allowed to separate before the loaded strip solution was drawn off.

Carbon adsorption studies were conducted using 20 grams of activated coconut carbon (30 by 140 mesh) in a 2.1-cm-diam by 29-cm glass column. The column was filled with wet carbon while a water meniscus above the surface of the carbon was maintained. Feed solution was passed through the column at a rate controlled by a stopcock on the bottom of the column. Flow rates through the column were generally limited to 5 ml/min.

After the feed solution had passed through the column, a 25-pct NaCl wash solution was used to remove entrained molybdenum from the activated carbon. Rhenium was then eluted with a 75-pct-methanol (MeOH), 25-pct-H2O mixture or a 75-pct-MeOH, 25-pct-H2O mixture containing 10 g/l NH4SCN. The activated carbon was regenerated with H2O.

Prior to loading on the carbon, the feed solution was labeled with 186 Re. Five-milliliter samples of all fractions recovered from the column were counted in a 3-in by 3-in NaI deep-well scintillation detector with a Rill Transistorized 400-channel pulse-height analyzer. This technique was useful for rapidly determining the movement of rhenium off of the carbon column.

Molybdenum and rhenium concentrations in the various process streams were determined by atomic absorption. Chlorate concentration was determined by the standard Kl-thiosulfate iodometric titration procedure.

Results and Discussion

Preliminary Carbon Adsorption Studies

Initial experiments were conducted in which rhenium was recovered from the electrooxidation process solution by adsorption on activated carbon. Activated coconut carbon (30 by 140 mesh) was found to exhibit superior loading capacity and physical characteristics and was therefore used in this study.

The rhenium content of the feed solution was adjusted to 100 ppm prior to column loading. No pH adjustment was made. The following observations were made as a result of the carbon adsorption tests:

- The hypochlorite ion (OCl-) decreased the adsorption of rhenium on the carbon.

- The chlorate ion (ClO3-) interfered with rhenium adsorption and lowered the loading capacity of the carbon for rhenium. Analyses indicated some ClO3- was coadsorbed onto the carbon.

- The MeOH-H2O elute was not effective in removing all of the rhenium from the activated carbon. Addition of SCN- to the MeOH-H2O eluate resulted in essentially complete recovery of rhenium from the activated carbon.

- The molybdate and sulfate ions in the feed solution had no apparent effect on the operation of the activated carbon column.

Additional adsorption runs were made in which the rhenium level of the feed solution was raised to 1,000 ppm. In these experiments, the preceding observations 1, 2, and 4 were valid, but observation 3 was not. Addition of SCN- to the MeOH-H2O eluate was not required for effective rhenium elution. In these runs, the carbon was loaded to approximately the same extent as in the runs using the 100-ppm-rhenium feed solution.

To prevent degradation of the activated carbon, it was necessary to decompose the excess hypochlorite ion. This was accomplished by reaction of hypochlorite with urea according to the following equation;

A stoichiometric amount of urea reduced all of the OCl- in 30 min at ambient temperature with no effect on the ClO3-.

Based on previous experience with larger scale electrooxidation studies, it would be difficult to produce solutions containing greater than 10 g/l Mo and 30 ppm Re. This limitation, in conjunction with the results of the activated carbon column experiments, dictated development of a technique for recovering and concentrating the molybdenum and rhenium from the process solution prior to separation of rhenium from molybdenum. Solvent extraction was considered as a possible method of accomplishing the recovery and concentration of molybdenum and rhenium.

Solvent Extraction Studies on As-Received Elox Solution

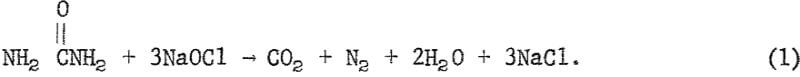

The quaternary amine was used in the initial solvent extraction experiments. The organic phase was comprised of 5 vol-pct quaternary amine and 5 vol-pct isodecanol (mixed isomers) as a phase conditioner in the acid-scrubbed kerosene. The organic phase was used for four successive extraction-stripping cycles. The feed solution contained 10 pct NaCl, 5.6 g/l Mo, 45 ppm Re, 38.6 g/l SO4=, and <5 g/l ClO3- at pH 8.5. The pH was adjusted to ~ 2.5 with concentrated H2SO4, The strip solution was a 1.5-M NH4OH solution containing 100 g/l NH4Cl. The phase ratio for both extraction and stripping was 1:1.

Results of the four cycles, presented in table 1, show that molybdenum was effectively extracted, but rhenium extraction decreased with successive cycles. Stripping operations were also unsatisfactory because more molybdenum was being retained by the organic phase with an increasing number of cycles. Presumably, the retained molybdenum was at least partially responsible for the decrease in rhenium extraction. This trend made it difficult to produce a pure rhenium fraction by extraction with a quaternary amine.

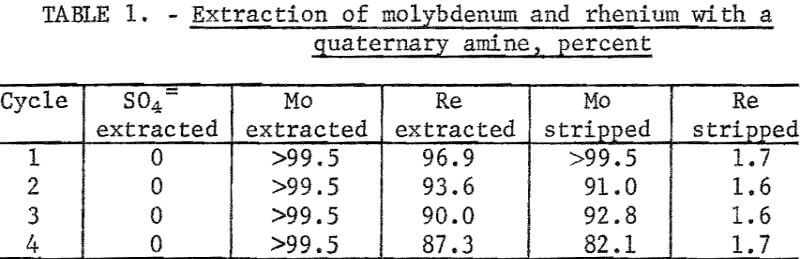

Chlorate in the feed might also have contributed to the unfavorable extraction and stripping obtained in the initial experiments. To test this hypothesis, parallel experiments were made with an artificial feed solution that had a composition similar to the one used in the preceding work, but contained no ClO3-. The organic phase used in this study was operated through nine cycles. The data in table 2 show that removing the ClO3- from the system was somewhat beneficial, but the general trend did not change, and the rhenium fraction remaining in the organic phase became more and more contaminated with molybdenum. Because of these problems, solvent extraction studies were shifted to an investigation of a tertiary amine system.

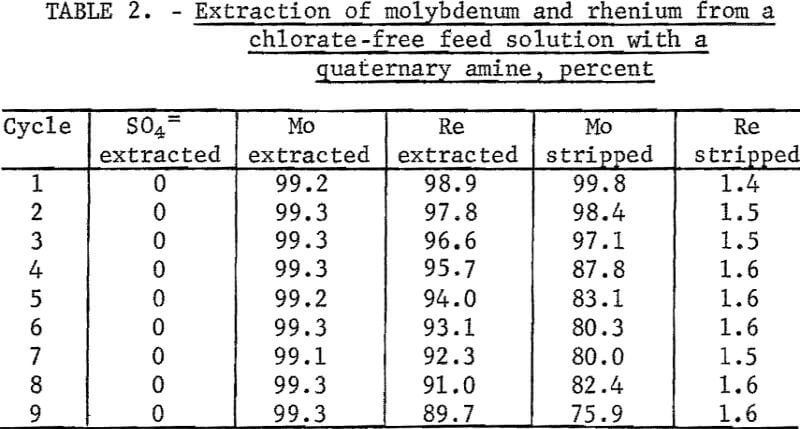

The tertiary amine was dissolved (12.5 vol-pct) in petroleum distillate. Stripping was accomplished with a 3-M NH4OH solution. The feed solution was essentially identical to that used in the quaternary amine studies. The organic phase was used for five extraction and stripping cycles.

Essentially all of the molybdenum and rhenium were extracted by the tertiary amine and stripped by the NH4OH solution, as shown in table 3. Little change in operating characteristics was noted with the increasing number of cycles. Unfortunately, about 50 pct of the ClO3- transferred to the strip solution. Thus, a tenfold increase in rhenium concentration obtained by solvent extraction with a tertiary amine would result in a fivefold increase in ClO3- concentration. This increase is undesirable since ClO3- interfered with rhenium adsorption in the initial experiments on activated carbon.

Reduction of ClO3- With SO2

Sulfur dioxide was the reducing agent of choice because it is inexpensive, easily handled, and could be used to lower the pH of the pregnant solution to the level needed for solvent extraction. Chlorate is reduced by SO2 according to the following reaction:

3H2O + ClO3- + 3SO2 → 3SO4= + Cl- + 6H+…………………………………………………..(2)

The effectiveness of SO2 was demonstrated in a series of experiments in which SO2 or an SO2-air mixture (1:7 volume ratio) was bubbled through 16 liters of Elox solution at the rate of 1.7 g/min SO2. The results of four experiments are presented in table 4. The first three experiments were successful in lowering both the ClO3- concentration and the pH to acceptable levels. The results of run 4 were not acceptable because an insufficient amount of SO2 was used. The solutions produced during runs 1 to 3 had a definite blue color denoting the formation of some reduced molybdenum species. For run 2, an airstream was introduced immediately after the SO2 flow was stopped, resulting in reoxidation of the reduced molybdenum within 30 min. In another run (data not shown), the reduced molybdenum species was reoxidized by adding 0.01 pound of sodium persulfate per pound of molybdenum. Better control of SO2 addition would probably prevent molybdenum reduction while yielding optimum ClO3- and pH reduction. The mole ratio of SO2 to ClO3- in run 2 was 3.5:1 versus the stoichiometric ratio of 3:1 predicted by equation 2.

Molybdenum and Rhenium Extraction and Separation From Treated Process Solutions

Combined solvent extraction and carbon adsorption runs were conducted with Elox solutions to demonstrate the effect of ClO3- reduction and molybdenum reoxidation on molybdenum and rhenium extraction and separation. An experiment (run 1 of table 5) was carried out on a feed solution that had been treated with SO2 to lower the ClO3- concentration. Reduced molybdenum species were not reoxidized. Extraction and stripping characteristics were favorable, but only 34 pct of the total rhenium was adsorbed on the carbon column. In run 2, SO2 was added to the feed solution, but only in an amount sufficient to lower the pH to 2. Under these conditions, no reduced molybdenum was formed, but the residual ClO3 concentration was still high, 9.7 g/l. Rhenium adsorption on the column was 98 pct, but 7.1 pct was washed off by the NaCl solution. Care was taken to prevent overloading of the column during the runs.

Sulfur dioxide treatment to lower the ClO3- concentration in the Elox pregnant solution, together with persulfate oxidation of the reduced molybdenum species, was utilized in the third run. This procedure was highly effective. Essentially all of the molybdenum and rhenium were extracted and stripped, and essentially all of the rhenium was adsorbed by the activated carbon and recovered in the MeOH-H2O eluate.

The conditions employed in run 3 were repeated in three larger scale runs (data not shown) in which the same organic phase and carbon, column were used for all three runs. The scale-up factor for solvent extraction was approximately 10. The adsorption column contained 300 grams (scale-up factor of 15) of activated coconut carbon to insure against column overloading. In all three runs, >99 pct of the rhenium reported to the MeOH-H2O eluate. Analysis showed that the rhenium product recovered from the eluate contained <0.1 pct molybdenum.

The preceding experiments demonstrated the accomplishment of the major goals of the study. Molybdenum and rhenium were recovered quantitatively from Elox process solution by solvent extraction. Rhenium and molybdenum were separated by selective adsorption of rhenium onto activated carbon. The rhenium was subsequently stripped from the carbon with a MeOH-H2O mixture. However, additional studies were necessary to develop techniques for recovering molybdenum from the column effluent and rhenium from the column eluate.

Recovery of (NH4)6Mo7O24 From Column Effluent

After passage of the NH4OH strip solution through the activated carbon column, the effluent contained mainly (NH4)6Mo7O24·4H2O. Samples of effluents from two column runs were evaporated to dryness to recover the (NH4)6Mo7O24·4H2O. Analyses of the two products obtained are given in table 6. The main impurity listed chloride ion, is present principally as a result of coextraction of chloride with molybdenum and rhenium by the tertiary amine. Some NaCl, and possibly KCl, appears in the precipitate as a result of poor separation of the carbon column effluent from the NaCl wash solution. The KCl probably occurs as an impurity in the NaCl used to prepare the brine wash solution.

Coextraction of the chloride ion by the tertiary amine can be minimized by careful control of the ratio of tertiary amine to molybdenum employed during solvent extraction. The effect of this ratio was studied using a feed solution containing 10 g/l Mo and 100 g/l NaCl at pH 1. The extraction phase ratio was 1:1, and the stripping phase ratio was 2.5:1 (organic phase to aqueous phase). Strip solutions were boiled to dryness, and an analysis of the solid products is presented in table 7. It is evident that decreasing the amine-to-molybdenum mole ratio does decrease the amount of Cl- in the product, but the amount of molybdenum extracted also decreased. Conditions that permit >99 pct molybdenum extraction result in a product containing 4.4 pct chloride ion, whereas extraction conditions that provide >90 pct molybdenum recovery result in a product containing 0.7 pct chloride.

These results were obtained in a single stage of extraction. Using multi-stage countercurrent extraction should greatly reduce the undesired coextraction of the chloride ion.

Recovery of NH4ReO4 From MeOH-H2O Eluate

The rhenium in the MeOH-H2O eluate was also contaminated with NaCl because of poor separation of the NaCl wash from the initial eluate fraction. Since a high-purity rhenium product was desired, it was decided to employ solvent extraction to eliminate the Cl-.

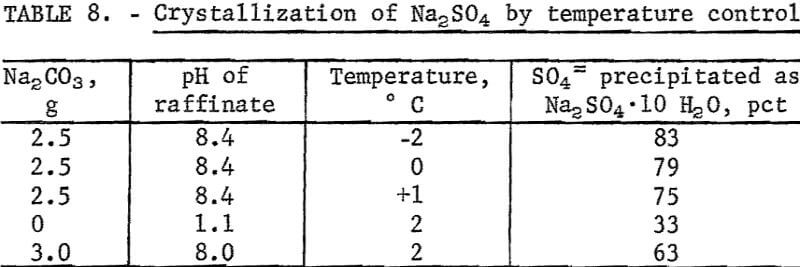

The MeOH in the 75-pct-MeOH 25-pct-H2O eluate was evaporated and recovered for recycling. The pH of the resulting aqueous liquor was lowered to and the rhenium was extracted with a tertiary amine and stripped with a 3-M NH4OH solution. The phase ratios in extraction and stripping were controlled to achieve a fivefold increase in rhenium concentration (to 30-40 g/l Re). The strip solution was then evaporated to 10 pet of its original volume and filters. The final NH4ReO4 product contained <80 ppm combined impurities, as shown from the following analysis of the solid product, in parts per million:

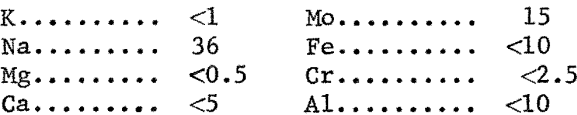

Figure 1 shows a generalized flowsheet for the process.

Recovery of Sulfate From the Solvent Extraction Raffinate

During the electrooxidation of molybdenite concentrates, sulfide is oxidized to sulfate ion. Because the raffinate from solvent extraction is recycled, its sulfate ion concentration would increase to saturation, possibly forming a Na2SO4 precipitate in the processing equipment. To prevent this, it is necessary to remove at least some of the sodium sulfate from the solvent extraction raffinate at each pass through the process.

Two techniques were investigated for removing SO4= from the raffinate: precipitation with CaCO3 or Ca(OH)2, and crystallization of Na2SO4 by lowering the solution temperature. The CaCO3 and Ca(OH)2 were relatively ineffective, precipitating only 10 pct of the sulfate ion, even when large excesses of the precipitants were used. Furthermore, CaCO3 and Ca(OH)2 increased the concentration of calcium in solution, thus raising the possibility of precipitating CaMoO4 during electrooxidation.

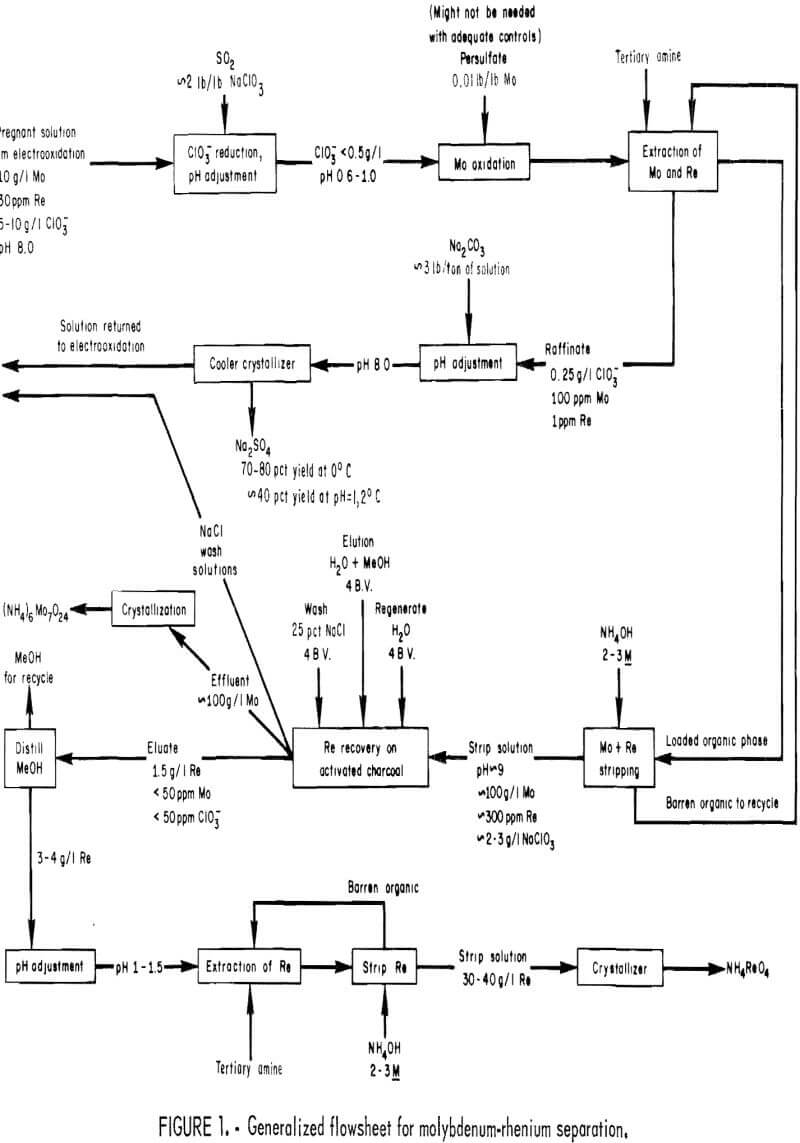

Crystallization of Na2SO4 was effected in both acid and base solutions by lowering the temperature of the raffinate to 0° C. The pH adjustment was affected using Na2CO3. Table 8 shows that as much as 83 pct of the SO4= can be crystallized as Na2SO4 at pH 8.4. These data also imply that the amount of precipitate is quite sensitive to temperature. Analysis of the dried Na2SO4 establishes a product purity of —96 pct; the remaining 4 pct is NaCl. This grade of Na2SO4 is sufficient for use in the paper industry.

Precious Metal Adsorption on Activated Carbon

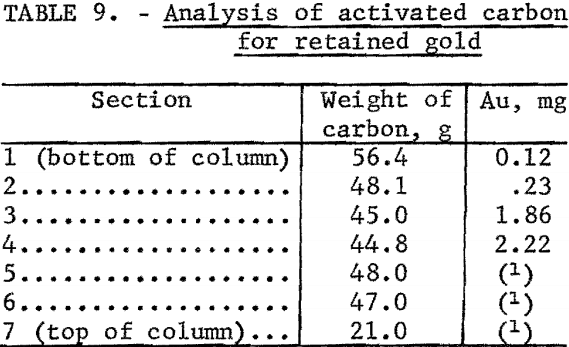

Some molybdenite concentrates contain small amounts of gold and silver. Electrooxidation can solubilize these precious metals along with molybdenum and rhenium. Analyses of activated carbon, which had been used for rhenium adsorption studies, revealed that gold and silver were being retained by the carbon. The carbon column from one rhenium adsorption run was sectioned and each section was checked for gold content. Results are presented in table 9. It is evident that the gold is not simply plated on the column but is carried down the column in an adsorption band. Qualitative tests conducted on an activated carbon column containing gold indicated that a MeOH-NaOH-H2O eluent would strip the gold from the carbon.

Conclusions

Molybdenum and rhenium can be extracted and separated from an electrooxidation pregnant solution by a combined process utilizing solvent extraction, carbon adsorption, and crystallization. Byproduct recovery of precious metals and Na2SO4 is possible.