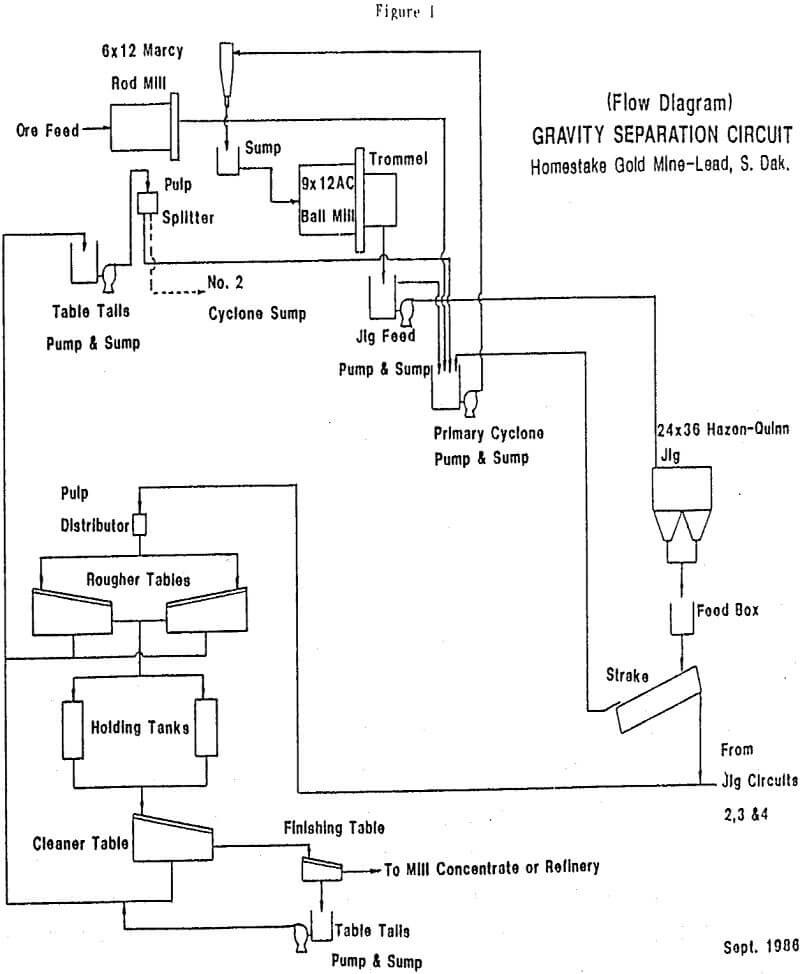

The project consisted of installing one jig and one belt strake on each of the four grinding sections. A portion of the circulating load in the ball mill circuit is pumped to the jig. The jig is placed over the top of the belt strake. The concentrate from the jig flows onto the belt strake. The tails from the jig return to the ball mill circuit. The belt strake concentrate passes by gravity flow to one of two full-size rougher tables. The tails from the belt strake are returned to the ball mill circuit. The concentrate from the rougher tables is sent to a storage tank for holding. The tails from the rougher cables are pumped back to the ball mill circuit.. The circuit is run on a continuous 24 hour-a-day basis.

The concentrate from the holding tanks is passed to a full-size No. 6 Deister concentrating table followed by a half-size No. 14 Deister table on four eight-hour-a-day shifts. The product from the half-size table is sent to the refinery for direct melting. The fifth eight-hour-day is used to clean up sumps and jig decks on two of the four units. The day shift gravity crew consists of three people. The continuous part of the gravity operation and the grinding circuits are handled by the present crew on the 24-hour-per-day, seven day-a-week operation.

The ore feed to the jigs is about 50% solids. Water is added to maintain a discharge density of about 40% solids. The concentrate ratio during startup was about 17 to 1. Presently the concentration ratio is 25 to 1. The eccentric stroke on the jigs is set at 3/8 inch. The vertical drop across the jig is 6 inches.

One of the main concerns was to minimize the amount of downtime required to redress the jig bed. These jigs have a basket arrangement which allows you to lift out and install a newly re-dressed set in a matter of minutes. The baskets which are removed are taken to a gravity recovery room for redressing. One problem encountered is all the wire, nails and cable collected in the jig baskets with the ¼ inch steel ball ragging. It was found that by using a half size No. 14 Deister concentrating table the ¼ inch steel balls can be separated from the wire, nails and cable. The wire will follow the course of concentrate to the top of the table and the steel balls fall into the tailing launder and are collected. This separation makes a very effective product to install back into the jig baskets for ragging.

Problems associated with the jig circuit were the selection of bearings used on the arm that controls the diaphragms to the jig hutches, slippage in the eccentric stroke adjustment, and excessive brass bushing wear. Solutions to these problems have all been made by a change in bearing manufacturing, by installing a locking bolt to the eccentric, and by an improved lubrication schedule.

The strakes were installed beneath the jigs for effective gravity flow use. The strakes were originally started at an 11° angle. The concentration ratio across the strake was 30 to 1 from the jig concentrate product fed to the strake. From sampling, it was determined that flat pieces of gold came off the strake belt with the tails. The strake was then dropped to a 7° angle. This changed the concentration ratio to 4 to 1. This solved the problem in flat gold loss.

Adjustable water sprays are situated at various areas on the belt. The water can be turned up or down thereby washing more or less product from the belt. The gold and heavier sulfides are retained in the ribs of the belt and report to strake concentrate. Strake tails return to the ball mill circulating load.

The strake is a very effective piece of equipment for surging flows and recovery of fine gold particles.

The strake concentrate flows through 4″ plastic pipe to the rougher table feed box. From there, one full size No. 6 Deister concentrating table is fed concentrate at 10% solids. A 30 to 1 concentration ratio is made across the table. The concentrate flows to a holding tank. The cable tailings are recirculated back to the ball mill circuit for regrinding. The other table is used when mechanical failure occurs from 24 hour per day operation in the gravity concentrating area. The tables are all enclosed in a highly secured area. Once the pitch of the table is set, necessary water adjustments are made from outside the security area. The water valves are adjusted while looking through an observation window. Additionally, cameras monitor the area for security and operation of the gravity concentrating circuit.

Problems associated with the gravity circuit have been wear in the feed boxes and pipe lines to the tables because of abrasives in the sulfides. Also, pumping the sulfides back to the ball mill circuit for regrind has created high wear in the pumps and valves and line plugging problems. Over the past year of operation most of these problems have been solved.

The concentrate stored in the holding tanks is run across a No. 6 Deister and a No. 14 Deister by two employees four (4) days per week. The final product from the finishing tables is sent to the refinery for direct smelting. Tails from both tables are returned to the grinding circuit. The present ratio of concentration across all the tables is about 1440 to 1 which results in a total ratio of concentration for the gravity system of 150,000 to 1.

The cleanup, which is the fifth day for the two employee crew from the gravity room, consists of cleaning up sumps in the rod mill and ball mill circuits where larger particles of gold are captured. This cleanup is done when one milling unit circuit is down for electrical inspection and scheduled maintenance. The crew takes the material from the sump and passes the material through a magnetic separator and then across a No. 14 Deister table for concentrating. The concentrate flows down to the rougher tables and the tails flow back to the ball mill circuit.