Table of Contents

- Electric Vibrating Feeder

- Dry (Belt Type) Reagent Feeder

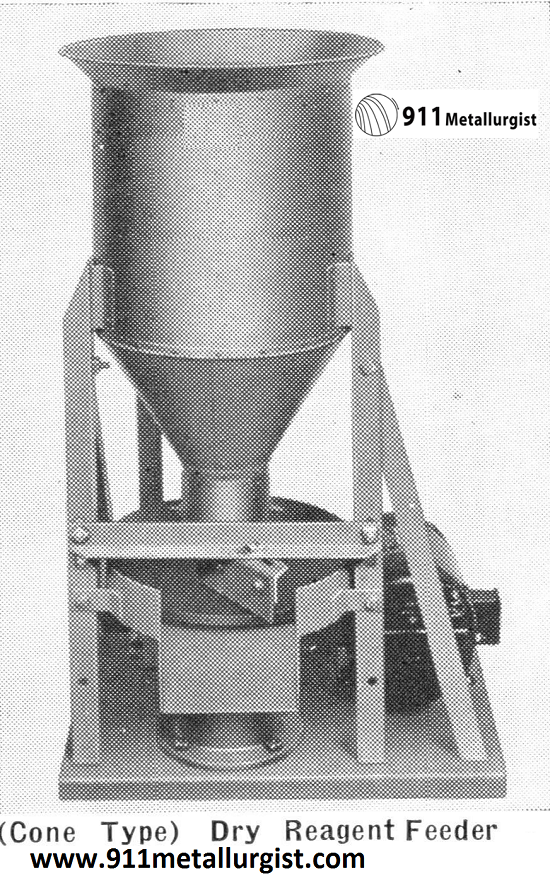

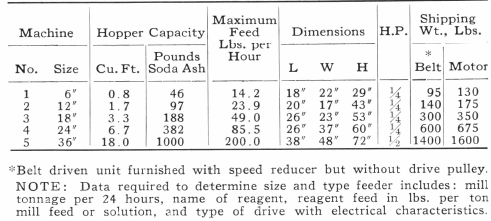

- Cone Type Dry Reagent Feeder

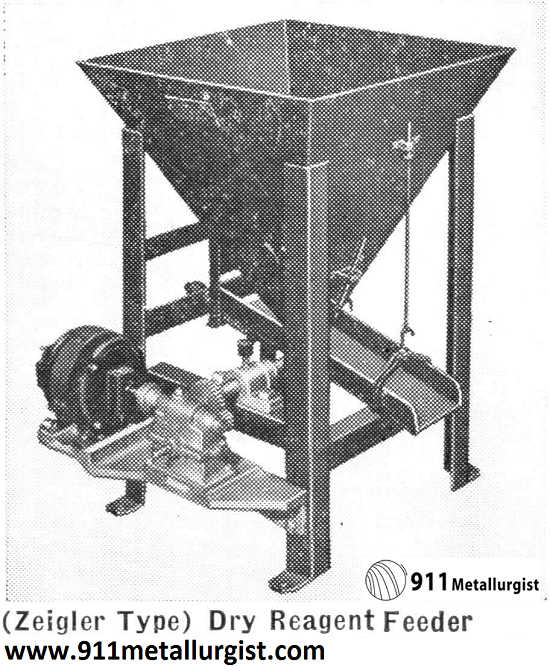

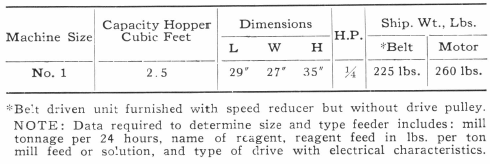

- Ziegler Type Dry Reagent Feeder

- Wet Reagent Feeder

- Multi-Compartment Wet Reagent Feeder

- Special Wet Reagent Feeder

- Laboratory Wet Reagent Feeder

- Bent Tube Type Laboratory Liquid Reagent Feeder

- Laboratory Liquid Reagent Feeder

- Mercury Feeder

Electric Vibrating Feeder

The Syntron Electric Vibrating Feeder is built on the same simple and strong principles as the Syntron Electric Vibrator. The vibrating trough is carried on two leaf springs and vibrated through the pulsating current of an electro-magnet. The speed of this magnet is controlled by a separate electric controller, which is furnished with each feeder. This controller is a totally enclosed unit arranged for mounting on a wall, either close to or quite a distance from the feeder. A manually operated dial rheostat controls the speed of the pulsating magnet and the flow of the feed. By a simple turn of the rheostat in the controller the feed can be changed from a thick, fast flow to a slow, minute one.

These feeders can handle practically every kind of dry feed, give accurate reagent control; even feed to a screen, crusher or conveyor. They can be supplied for suspension-mounting in the larger sizes, as well as the standard floor- mounting on a heavy base. Due to construction there is no wearing of mechanical parts, or abrasion of trough.

A variety of different sizes is available from the small reagent feeders, up to the “Heavy Tonnage” model, which will handle up to 1200 tons per hour of heavy ore and rock.

These are also available as special “Heat Resistant” furnace feeders, or equipped with a grizzly discharge, especially suited to separate fines from the flow of coarse material feeding into a crusher or other machine.

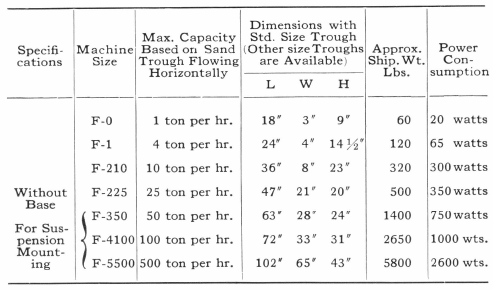

Capacity

F-0 and F-1 available for 110 or 220 Volt AC.

F-210, F-225, F-350 available for 110 or 220 or 440 Volt AC.

F-4100 and F-5500 available for 220 or 440 Volt AC.

Dry (Belt Type) Reagent Feeder

(Belt Type) Dry Reagent Feeder is particularly well suited to feeding reagents, such as lime or soda ash, which become lumpy or sticky and tend to clog hopper type feeders in any but a very dry climate. Also, any dry reagents used in very small quantities, such as zinc dust in cyanide precipitation, are most conveniently and accurately fed by this belt type feeder.

Continuous test laboratories require ore fed at the rate of 100 to 200 lbs. per hour while reagents must be fed in very small quantities. This unit is ideal for both operations, providing accuracy essential for uniform results in laboratory test work.

A step-cone pulley drive controlling speed of belt, skirt boards adjustable from center to edge of belt to control width of feed, and depth of reagent on belt, provide three adjustments for accurately controlling quantity of material fed. Drives for higher belt speeds can be provided to increase capacity. Pressed-steel head and tail pulleys, and babbitted bearings ensure reliable, continuous operation.

On motor driven feeder the fractional horsepower sleeve- bearing motor and speed reducer may be mounted on the ton, side or bottom of the unit.

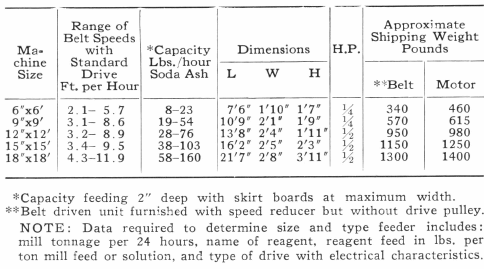

Capacity

Cone Type Dry Reagent Feeder

(Cone Type) Dry Reagent Feeder is the most commonly used feeder for dry reagents except for those that absorb moisture readily and tend to become lumpy or sticky. This feeder is lower in cost than the belt type and is compact and easy to install ahead of bad mill, over a conditioner or in any other part of the circuit.

Three adjustments are provided for varying rate of feed— a step-cone pulley drive permits adjustment by speed change, an adjustable collar on the hopper bottom allows for full range of feed rate at each drive speed, and the scraper may be set to cut any desired width of reagent from the rotating disk. This allows very accurate feeding through a wide range of feed rates as all adjustments are positive.

A coarse screen across the top of the hopper prevents lumps entering when filling and a stirring rod attached to the rotating disk insures a smooth gravity flow onto the disk. A rib or scraper on the underside of the rotating disk moves the reagent falling into the pan under the disk out to the spout for discharge.

The (Cone Type) Dry Reagent Feeder is of all metal construction rigidly mounted on a steel base. Rotating disk is mounted on a totally enclosed vertical speed reducer which is driven by a motor and step-cone pulley drive. Standard motor driven unit is equipped with a ¼ H.P. single phase, 60 cycle, 110 or 120 volt, 1800 r.p.m. sleeve bearing motor. This durable construction assures dependable, trouble free operation with a minimum of attention by the operator.

Capacity

Ziegler Type Dry Reagent Feeder

(Zeigler Type) Dry Reagent Feeder is a cam-actuated shaker feeder which consists of a pyramid-shaped welded steel hopper supported on a welded steel framework. The cam-actuated shaking pan stroke can be varied by means of a screw. Motor and speed reducer on the motor driven type are mounted on a welded steel base that is bolted to the feeder frame. This unit is easily regulated for accurately feeding dry reagents and is a simple, inexpensive feeder.

Capacity

Wet Reagent Feeder

Today mill men are continually experimenting with new reagents, not only to secure higher grade concentrates and lower tailings, but also to reduce reagent costs per ton. Wet Reagent Feeder is a compact, self-contained unit mounted on a wood base. It occupies minimum floor space and may be conveniently placed near the grinding or flotation circuit as required.

The Wet Reagent Feeder is equipped with a revolving disc, carrying a variable number of cups around its outer rim. Micrometer adjustment is easily and quickly made with a convenient handwheel which moves the drip trough in or out to increase or decrease the amount of reagent caught in the trough, giving accurate control of reagent feed. The speed of the disc may be varied if desired and a float valve is provided to maintain constant level of reagent in the tank. Adjustments have been reduced to a minimum to simplify control. A tank cover is furnished on the No. 12 size to keep reagent clean.

The Duplex Wet Reagent Feeder combines two standard simplex wet reagent feeders on a single base and driven by a motor through a speed reducer. Belt drive may be furnished if desired. Advantages of two simplex feeders are thus secured at only a slight increase in cost.

The No. 12 Wet Reagent Feeder is ideal for use in laboratory continuous test plants and mills up to 150 tons and larger, depending on reagent feed rate required.

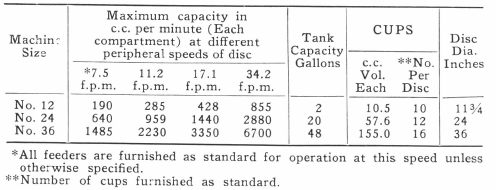

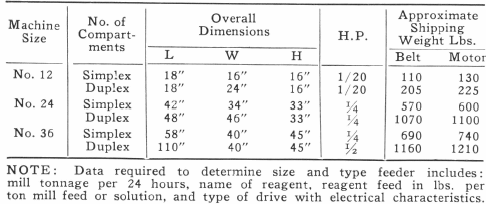

Capacity

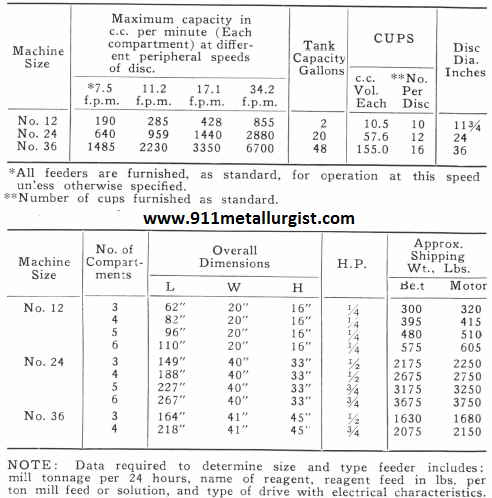

Multi-Compartment Wet Reagent Feeder

Multi-Compartment Wet Reagent Feeder is used where a central point of re¬agent distribution is desired. This feeder, in the No. 12 and No. 24 sizes, is furnished in three, four, five, and six compartment units combined in one compact assembly. This allows the feeding of a large number of reagents simultaneously. Four compartments are maximum on the No. 36 feeder.

The revolving disc, tank, and micrometer control of every compartment are the same as those on the Standard Simplex Wet Reagent Feeder. The discs are rotated from a common drive by a motor through a speed reducer. Belt drive may be furnished if desired. The drive is positive and insures constant disc speed under all conditions.

Special compartments for feeding aerofloat, cyanide, or acids substituted without altering driving mechanism or base.

Capacity

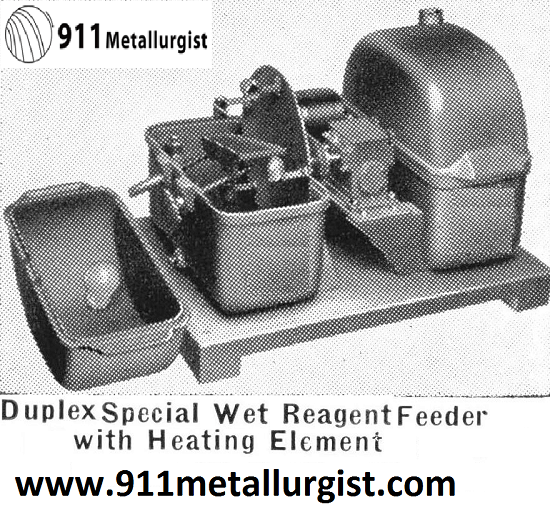

Special Wet Reagent Feeder

Special Wet Reagent Feeder is designed for handling reagents of a corrosive nature such as aerofloat, cyanide, and the various acids normally used in flotation. This special feeder can be used as an individual unit or as special compartments in Multi-Compartment Wet Reagent Feeders.

In the Aerofloat Feeder, all parts coming in contact with the liquid are non-corrosive. A light bulb under the tank cover keeps the liquid warm and easy flowing. The copper sulphate feeder consists of a standard feeder and a heavy lead cylindrical tank in which is placed copper sulphate crystals. Water is introduced in this tank from the feeder and the resulting saturated copper sulphate solution overflowing the tank then is introduced into the conditioner or flotation circuit by gravity. Feeders for cyanide solution are available and materials readily attacked by cyanide such as copper and brass, are eliminated.

Special Wet Reagent Feeder is available in the No. 12 and No. 24 sizes in simplex, duplex, and multi-compartment units with capacities, etc., as listed under the Wet Reagent and Multi-Compartment Wet Reagent Feeders. Submit your special wet reagent feeding problems to us for recommendation.

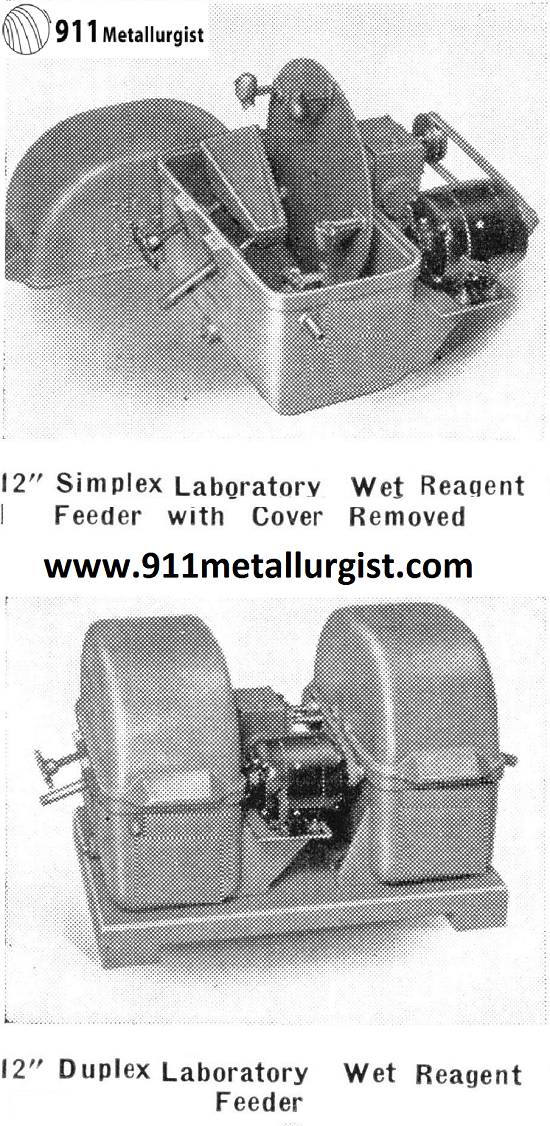

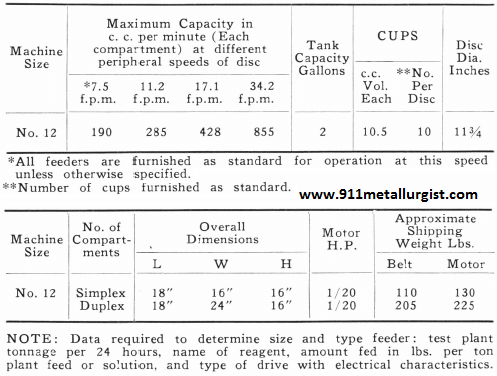

Laboratory Wet Reagent Feeder

Laboratory Wet Reagent Feeder is ideal for use in laboratory continuous test plants. This feeder is a compact, self-contained unit mounted on a wood base. It occupies minimum space and may be conveniently placed near continuous test plant grinding or flotation circuit as required.

The Laboratory Wet Reagent Feeder is equipped with a revolving disc, carrying a variable number of cups around its outer rim. Micrometer adjustment is easily and quickly made with a convenient handwheel which moves the drip trough in or out to increase or decrease the amount of reagent caught in the trough, giving accurate control of reagent feed. The speed of the disc may be varied if desired and a float valve is provided to maintain constant level of reagent in the tank. Adjustments have been reduced to a minimum to simplify control. Covers for tanks are furnished to keep reagent clean.

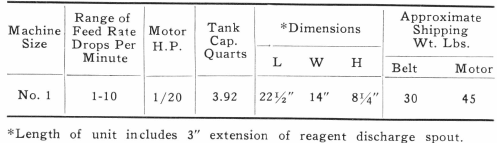

The Duplex Laboratory Wet Reagent Feeder combines two standard simplex wet reagent feeders on a single base and driven by a motor through a speed reducer. Belt drive may be furnished if desired. Advantages of two simplex feeders are thus secured at only a slight increase in initial cost.

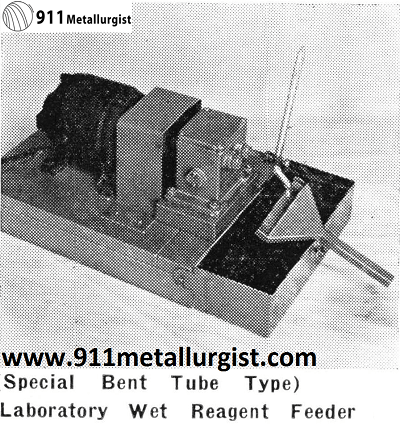

Bent Tube Type Laboratory Liquid Reagent Feeder

The (Special Bent Tube Type) Laboratory Wet Reagent Feeder is a very accurate feeder for wet reagents in quantities as low as one drop per minute. It is ideal for applications where it is essential to have very exacting control of minute amounts of reagents.

This unit was developed in the Ore Testing Laboratory and is available as a complete feeder, or as an attachment or converting any of the disc type feeder mechanisms to this type feeder by removal of the cups and attachment of the dip tube. The complete unit consists of a 1/20 H.P., 110 volt, single phase, 60 cycle, sleeve bearing motor direct connected with a speed reducer with a disc mounted on the speed reducer shaft. Three dip tubes for attachment to disc are provided with each unit. Capacity of these tubes is varied by distance of inlet hole above bottom tip of tube. Tubes have capacities varying respectively from 1 to 3, 3 to 6, and 6 to 10 drops per minute. A 20 gauge riveted and soldered steel tank, supported on the end of the base by hooks so it is easily detached, stores the reagent. This simple, inexpensive unit is ideal for use in continuous testwork such as with a No. 5 or No. 7 Continuous Test Plant.

Laboratory Liquid Reagent Feeder

Laboratory Special Wet Reagent Feeder is designed for handling reagents of a corrosive nature such as aerofloat, cyanide, and the various acids normally used in flotation. In the Aerofloat Feeder, all parts coming in contact with the liquid are non-corrosive. A light bulb under the tank cover keeps the liquid warm and easy flowing. The copper sulphate feeder consists of a standard feeder and a heavy lead cylindrical tank in which is placed copper sulphate crystals. Water is introduced in this tank from the feeder and the resulting saturated copper sulphate solution overflowing the tank then is introduced into the conditioner or flotation circuit by gravity. Feeders for cyanide solution are available and materials readily attacked by cyanide are eliminated.

Laboratory Special Wet Reagent Feeder is available in No. 12 simplex or duplex units with capacities, etc., as listed under the Laboratory Wet Reagent Feeder. Many factors enter into the preparation and feeding of various corrosive and other special reagents. Let us engineer equipment for your special wet reagent problem.

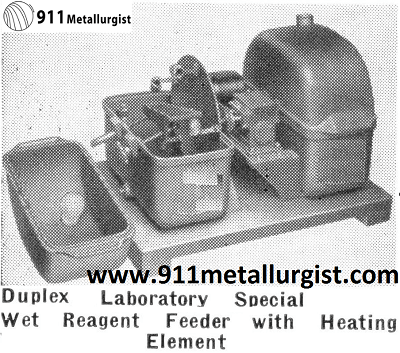

Mercury Feeder

The Mercury Feeder is recommended for accurate feeding of mercury into various amalgamating devices, and the amount delivered can be varied from practically nothing to one-half ounce troy per drop. To adjust the feed of mercury it is only necessary to open or close the valve. The feeder is driven by a small round belt from any line shaft or can be driven by a small gear motor. It is solidly constructed to stand up well under adverse operating conditions and maintain accuracy. Unit weighs 25 lbs. complete.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.