Table of Contents

The knowledge of particle size distributions is a critical factor in the monitoring, control and optimization of many processes. This is particularly true of the mineral beneficiation industry, where comminution, the reduction of particle size, accounts for a major source of the processing costs. As an example, it is not uncommon in current taconite operations on the Minnesota Mesabi Range and in Upper Michigan to grind the highly refractory crude ore to 85 percent passing 325 mesh before mineral values are sufficiently liberated to give a marketable product following concentration. It can therefore be appreciated that a small percentage of overgrinding can increase significantly plant production costs and decrease output. In order to optimize a grinding operation, and in turn the beneficiation process, it is highly desirable to have a measuring system that can rapidly determine particulate size at various points in the process stream.

A significant research effort has been expended on the development of an analyzer capable of providing rapid size analysis of particle distributions which is suitable for on-stream control application. Several systems are either in the advanced stages of development or have been recently introduced to the commercial market. These systems involve the application of such principles as light and laser interruption phenomena, electrical resistance, light scattering, air elutriation, and sedimentation-radiation attenuation.

There are a number of major limitations in the application of the preceeding particle analyzing systems. Varying from system to system, these limitations include the need for a highly dispersed and diluted feed sample, a non¬opaque fluid medium, a very small sample size (which can result in processing of nonrepresentative samples) and extrapolation of size distribution from

very limited data. In many instances, difficult and lengthy standardization procedures are required. The work presented in this paper covers an investigation by the Bureau of Mines at the Twin Cities Metallurgy Research Center in which a prototype analyzer using hydrosizing-radiation attenuation methods was developed for rapid particle size analysis. This system overcomes many of the aforementioned problems associated with other particle sensing systems. The system described was developed for application in iron ore beneficiation plants and for monitoring particle distributions of homogeneous materials. It is probable that, in addition to iron oxide-quartz materials, the system could be further adapted for use on other heterogeneous materials.

Principles of Analyzer System

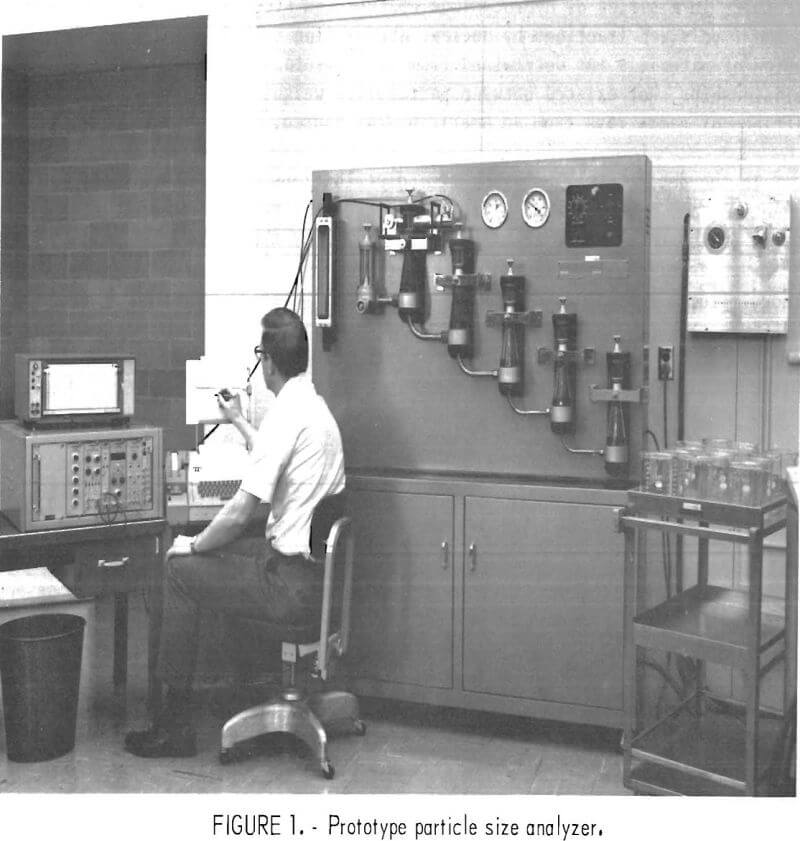

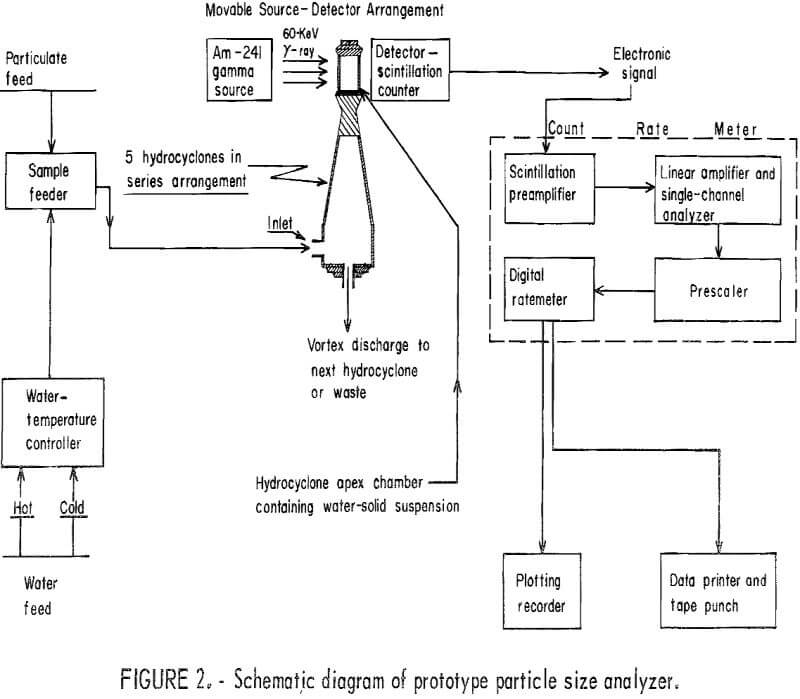

A prototype particle size analyzer system was developed that can rapidly process representative samples of an iron ore-water slurry (fig. 1). Size distribution of mineral particles in the 74~micrometer (200 mesh) to 7-micrometer size range is determined. A schematic diagram of the system is shown in figure 2. The operation of a sizing cycle begins with the injection of a known weight of slurried solids into the first of a set of five hydrocyclones connected in a series arrangement. Particle elutriation is accomplished in each successive stage of the sizer with the largest particles deposited in the closed apex chamber of the first cyclone and the smallest retained particles deposited in the final cyclone. Density of the solids-water slurry in each apex chamber and ultimately the weight of the sized solids is determined by the relative attenuation of a gamma ray beam of the suspended mineral particles. Particle size distribution data can then be

presented in terms of the Gaudin-Schuhmann function or by some other means such as a histogram or a percent passing some limiting size.

Hydrosizing

The sizing device used in the development of the analyzer system is a modified Warman Cyclosizer. Principles of operation and developmental work on this apparatus are reported by Kelsall and McAdam. Modification of the hydrosizer consisted of the addition of a hot-cold water mixing apparatus for automatically controlling elutriation water temperature and the bolting of fixtures near each cone for accurate positioning and holding of the source-detector equipment.

Particle sizing by the Warman Cyclosizer is accomplished in a series arrangement of five inverted hydrocyclones that allow the normal apex discharge solids to be retained in each closed apex chamber. A continuous reflux sorting of the particles is accomplished with particulates less than some limiting size being passed on to the next cyclone for subsequent sizing.

With inlet and vortex finder diameters becoming smaller in each subsequent cyclone, water velocity and centrifugal forces are increased at a fixed water flowrate, thus the limiting particle size for each cone becomes progressively smaller. By increasing water flowrate after elutriation of the sample, solids retained in each hydrocyclone are forced upward into the apex chambers giving a homogeneously distributed water-solids mixture. In normal operation of the Warman Cyclosizer, solids are discharged separately, dried, and weighed to determine the size distribution. The prototype sizer overcomes this lengthy drying and weighing procedure by determining the weight of sized particles while suspended in the apex chambers. To insure reproducible results, a standard procedure for sample preparation and introduction into sizer was followed, while elutriation time and water flowrate and temperature were held constant.

Particle Sensing

Weight of sized particles suspended in the hydrosizer apex chambers is determined by a highly sensitive nuclear densitometer. Gamma radiation was used in this application. In 1954, Brown and Skrebowski discussed the use of X-ray absorption in determination of particle size in a sedimentation apparatus. Later work was done by Gaudin and Fuerstenau and more recently Olivier and Hickin published results of development work on an automated apparatus that determines particle distribution in the subsieve range using X-ray absorption. Ross conducted somewhat similar sedimentation sizing experiments using gamma radiation and suspensions of uranium oxide.

Low-energy gamma radiation was used in this study because of its relatively high sensitivity to composition at short path lengths. Americium-241 was chosen as a source because of its stability, long half-life of 458 years, and high abundance of 60-KeV energy gammas. A 2-millicurie encapsulated source, contained in a shuttered housing, was used in the investigation. Development work was done with a source-detector arrangement that could be readily moved and relocated on each of the five hydrosizer apex chambers.

The mass of solids contained in the individual apex chambers is related directly to the attenuation of the gamma beam. Attenuation of gamma radiation by a suspension of particles in a cell may be expressed by the following equation (11):

I = Io e µPx…………………………………………………………………..(1)

where Io = the intensity of the incident beam,

I = intensity of the transmitted beam,

X = distance traversed,

µ = mass absorption coefficient of absorbing matter,

and p = density of absorbing matter.

Intensity of radiation reaching the detector is proportional to the resulting pulse count rate. Radiation is attenuated not only by the suspended solids but also by the chamber walls, water, and air gaps. However, since the geometry of the apparatus and composition of suspended components are held constant in this work, equation 1 can be further simplified;

y = Ae-Bw………………………………………………………………………………….(2)

where y = gamma radiation transmittance (pulse count rate) ,

A = constant accounting for apparatus geometry and source (equal to pulse count rate with water in cell and no particles in suspension),

B = a constant dependent on the composition of the attenuator,

and w = weight of attenuator.

Electronics

The gamma ray detector consists of a 25.4-millimeter-diameter by 5-millimeter-thick sodium iodide, thallium-activated scintillation crystal connected to a photomultiplier tube (fig. 2). The electronic signal generated in the detector is sent through a scintillation preamplifier to a linear amplifier and single-channel analyzer. The single-channel analyzer is adjusted to pass only those pulses originating from the Americum-241, 60-KeV gamma rays. Following prescaling (a factor of 10), the pulse signal is passed to a digital-rate meter where the intensity of the partially attenuated gamma beam is visually displayed and sent to a plotting recorder and data printer.

Procedure

The water-temperature controller was set at a predetermined temperature, normally 20.0 ±0.5° C, and water was pumped at a constant flow rate through the series of hydrosizer cyclones. While water temperatures were stabilizing, the electronic instruments were standardized, and the Americium source was rotated into an unshuttered position allowing the gamma ray beam to be directed through the apex chamber of the first cyclone. Ten-gamma count-rate readings of 20-second duration were taken in succession and averaged to give the base rate for each cyclone, thus determining constant A for equation 2. A base count rate was established for each of the five cyclones by successively moving the sources-detector system over each cyclone apex chamber.

After system standardization, a known weight of dispersed and suspended solids was injected into the hydrosizer at a water flow of about 45 percent greater than final elutriation flow rate. This gave a preliminary distribution of solids in the cyclones, and after 3 minutes the water was reduced to a final flow rate, usually 9.5 liters per minute, and sample elutriation continued for 20 additional minutes. Following elutriation, flow rate was again returned to the high setting and transmittance readings were taken on each of the apex chambers containing the sized, suspended particles. Solids were discharged from the apex chamber, collected in separate beakers, dried, and weighed. Solids elutriated from the last cyclone were calculated by difference.

Experimental Results

Preliminary test work on the particle sizing-sensing system involved evaluation of a number of possible variables that might affect reproducibility and accuracy of particle sizing and weight determinations. Elutriation time, water temperature, flow rate, and specific gravity of solids are all known to affect particle size separation in the hydrosizer. The first three variables were fixed at levels that would allow optimum particle retention of minerals commonly found in iron ores. Specific gravity values were dependent upon the mineral under investigation.

Three minerals (quartz, hematite, and magnetite) were selected for study in early phases of the investigation, while later combinations of these minerals and a partially concentrated magnetic taconite ore (semiconcentrate) were studied. The quartz sample containing less than 1 percent contaminants was prepared from a 2.65-specific-gravity beach sand that had been dry ground to minus 74 micrometers and acid leached to remove soluble contaminants. The hematite material was prepared from selected, dense lumps of high-purity ore by dry grinding to minus 200 mesh. This sample had a specific gravity of 5.17 and contained less than 1 percent contaminants, mostly as silica. The magnetite sample was prepared by high-pressure, caustic leaching a commercial high-grade magnetic taconite concentrate. The minus-74-micrometer fraction used in the study was 99.3-percent pure and had a specific gravity of 5.12. A semi-concentrate product from a taconite plant was used in the latter stages of the development and consisted primarily as a bimineral assemblage of magnetite and quartz with minor amounts of hematite and silicates. The minus-74-micrometer fraction contained 12.8-percent silica.

Temperature of elutriation water; one of the main variables of the hydrosizer, not only affected particle separation, but also the attenuation of the gamma beam. The lower the temperature, the greater the density, and the greater the attenuation by a given volume of water. Temperature variations of less than ±1° C were found not to significantly affect transmittance values. Once the effect of water temperature had been established, it was held constant at 20° ±1° C throughout the remainder of the experiment.

Count rate, a direct measurement of the gamma beam intensity, with only water in the apex chambers was about 22,000 counts per second for each of the hydrocyclones. Count rates of 20-second duration were used in these experiments to represent gamma ray transmittance

Single-Mineral Experiments

Experiments using several quartz fractions were run to determine what effect, if any, particle size might have on gamma ray attenuation. Varying quantities, 1 to 10 grams, of six sieve fractions ranging from minus 65 mesh plus 100 mesh to minus 325 plus 400 mesh were alternately suspended in the first cyclone apex chamber. Gamma attenuation by the quartz particles in this size range was found to be dependent only upon the weight of the suspended solids and independent of particulate size

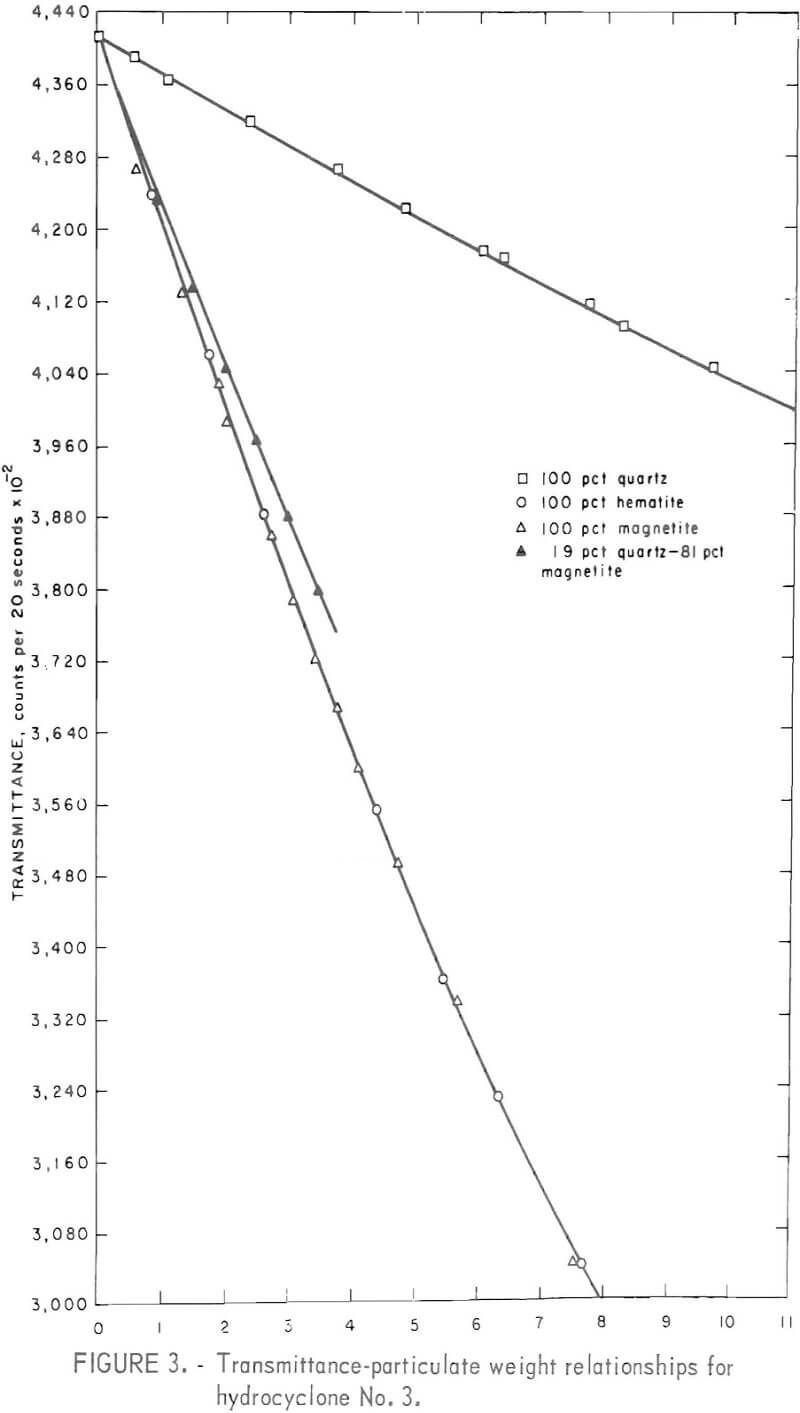

Transmittance-particulate weight relationships were developed by an extensive series of individual sizing and transmittance determination tests for the pure minerals, quartz, hematite, and magnetite. By varying the quantity of mineral fed into the hydrosizer, a varied but controlled amount of mineral was separated and collected in the individual apex chambers: Typical of the data obtained for all five hydrocyclones, experimental data from hydrocyclone 3 are plotted in figure 3. Curves connecting data points are exponential and are very accurately described by equation 2, given earlier.

As would be expected, attenuation coefficient values increase for higher atomic number attenuators. In this case, hematite and magnetite have a significantly greater effect on gamma ray attenuation than quartz. Hematite and magnetite materials used in these experiments have approximately the same attenuation coefficients; that is, attenuation-particulate weight data fall on the same curve. This probably resulted from the combined offsetting effects of density and chemical composition differences. The iron oxide minerals were about 4.9 times more effective than quartz in attenuating the gamma beam.

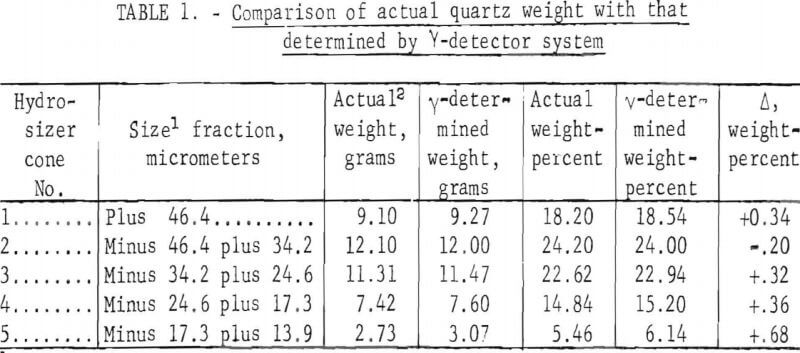

Results from a typical test where pure quartz was sized are given in table 1. Particulate fraction weights were determined both by the gamma-electronic sensing system and by weighing the fractions of sized material. Excellent correlation was found between material actually weighed and weight of individual fractions that had been determined with the gamma-detector system using the mathematic relationship given in equation 2.

Two-mineral Experiments

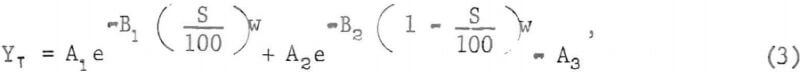

Following experimentation on single-mineral systems, research work was undertaken on a laboratory prepared two-mineral combination of 85 percent magnetite and 15 percent quartz to develop a procedure and mathematical model that would appropriately describe the expanded system. The two-mineral model was developed from an extension of equation 2 and relates total gamma transmittance and weight of sized solids suspended in the apex chambers

where Yt = gamma radiation transmittance (pulse count rate) in presence of mineral suspension,

A1, A2, A3 = constants accounting for source and apparatus geometry,

B1, B2 = constants dependent upon mineral composition,

S = percent concentration of one of the mineral constituents (SiO2 percent in this case),

and W = weight of suspended solids.

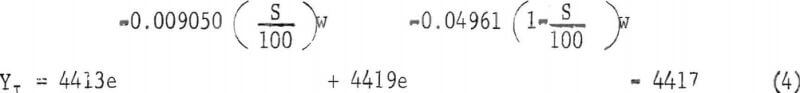

Tests were run using the magnetite-silica mixture in which total weight of sized material was varied while holding the mineral ratio approximately the same. Results from hydrocyclone 3, typical of all five of the hydrocyclones, are presented in table 2 and figure 3. Comparison of actual weights with those computer calculated (from transmittance data) show an average of 2-percent difference. Values for constants derived during single-mineral tests were substituted directly into equation 3 for these calculations.

This equation was as follows:

Results from this test series indicate that the weight of individual fractions of high-ratio magnetite-quartz feeds can be predicted to a high degree of accuracy with this model. The excellent data fit also can be interpreted as an indication of near ideal behavior of these minerals with respect to gamma ray attenuation.

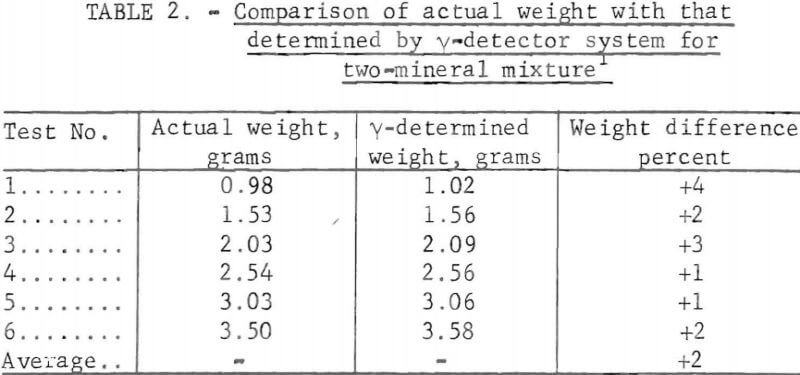

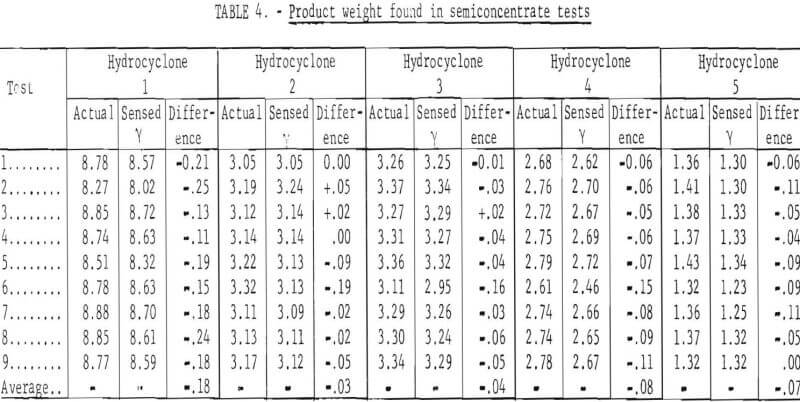

Capabilities of the sizing sensing system to determine size distribution of typical plant products were evaluated using a semiconcentrate from a magnetic-taconite processing operation. The material tested was a cyclone overflow product from the secondary ball mill circuit and was made up primarily of liberated magnetite and quartz minerals. Mathematical relationships and constant values developed in the earlier tests on the synthetic magnetite-quartz system were applied in these tests.

As a means of determining system reproducibility and accuracy, nine replicated tests were run using 25 grams of the semiconcentrate as feed for each test. Data and constant values are presented in tables 3 and 4. Results show that the two-mineral model reliably and accurately predicts the weight of all five sized products. On a basis of percent total feed, the largest average value for the difference between sensed and actual product weight is 0.7 percent and the smallest is 0.1 percent. Noting that weight differences are one-sided, predominantly negative, there appears to be some possibility of further improvement in weight prediction by adjusting the model to include a small magnetite-quartz interaction term.

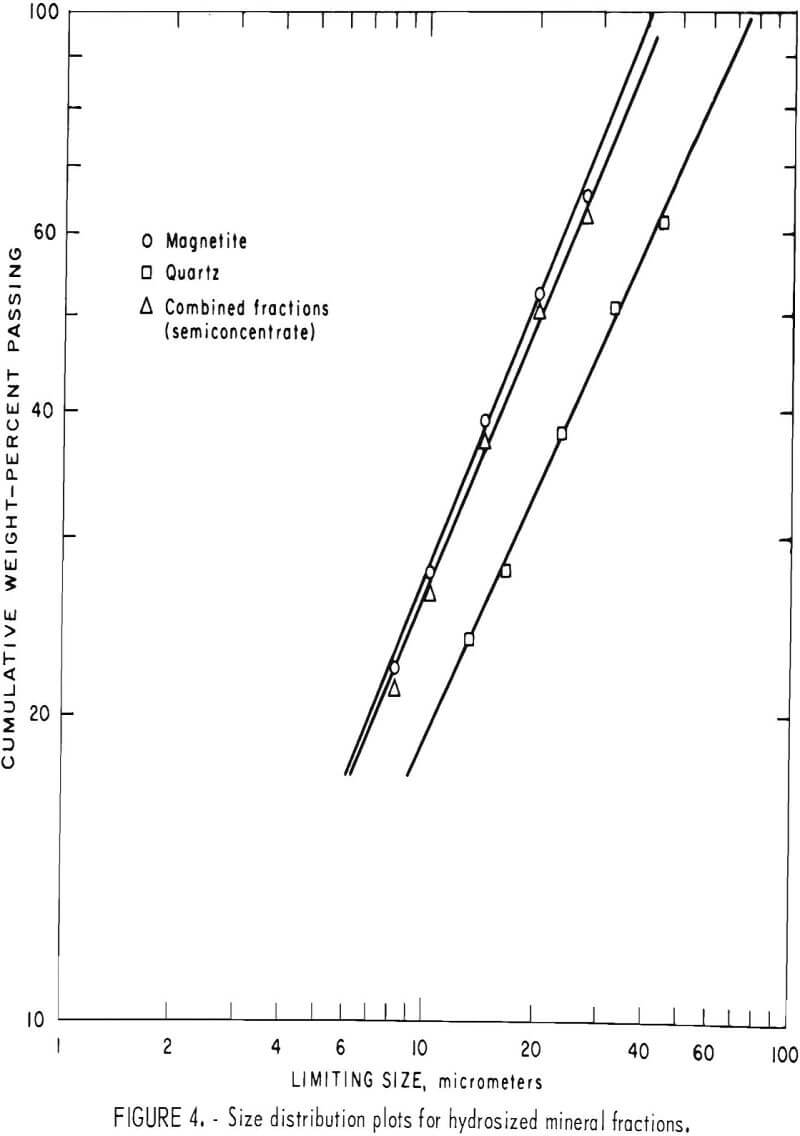

It is necessary to adjust the preliminary size distributions that are determined by the size analyzer because of specific gravity differences between quartz and magnetite of the semiconcentrate feed. A given hydrocyclone will contain larger sized quartz particles than magnetite because of settling-rate differences. An adjusted size distribution is developed by a process of first representing each mineral fraction as separate Gaudin-Schuhmann functions, recalculating the two functions on a common limiting size, adding the gram weights for each mineral, and finally determining a single new size distribution. Results are given in table 5 for the size computation using the semiconcentrate, while figure 4 shows the plotted Gaudin-Schuhmann functions for the three materials.

![]()

A statistical evaluation was made using the nine replicated tests to determine the degree of predictor accuracy that can be assigned to the size analyzer. Calculations showed that with a 25 gram hydrosizer feed sample, the size determining system would predict weight-percent for individual fractions with an accuracy of ±0.85 percent or better at a 95 percent confidence level.

It is noted that certain assumptions must be made and that the chemical composition of the mineral feed must be known with some degree of accuracy before an adjusted size distribution can be calculated. It is important that particles in the analyzer feed be liberated that is all particles are homogeneous. In the situation where finely comminuted iron ore concentrates or semiconcentrates are sized, the predominant minerals present, hematite or magnetite and quartz, have large differences in specific gravity. If a significant portion of the sample were unliberated two-mineral particles, some problem will be encountered as a result of specific gravity differences in making the final size distribution adjustment, particularly if the fraction of unliberated particles varies from sample to sample. Generally the mineral particles in concentrates and semiconcentrates are well liberated, and therefore, do not pose an important problem

The percent concentration of one of the mineral constituents must be known when determining the size distribution of two-mineral materials. The accuracy requirements placed on the final size distribution values will in turn determine the accuracy with which the mineral assemblage of the feed must be known. In many cases, figures based on prior sample analysis experience would be sufficient for size calculations if the product composition was not changing significantly. Recent developments in the “on-line” analysis field using new or improved nuclear and X-ray techniques will allow accurate prediction of mineral constituents in the analyzer feed and products,

Analyzer Prototype

Beyond the scope of this work is the development of an industrial on-stream analyzer based on the research system that has been discussed in this paper. The present system uses a manual method for feeding the particulate sample into the analyzer; however, sample feed could be handled by an adaptation of the automated system that has been developed for on-line chemical analysis of taconite slurries, described by Tuttle and Blake.

The sample preparation and feeding system would pulse a known weight of particulates into the sizing system. Density determinations would be made simultaneously at each of the five hydrocyclone apex chambers rather than moving a single density gauge from hydrocyclone to hydrocyclone. Equipment sequencing and particulate size calculations would be handled by a computer and time clock. An analysis of the various elements of the proposed particle analyzer has been made, and calculations indicate that sample cycle times of 10 to 15 minutes could be expected.

Conclusions

A prototype analyzer system has been developed that will rapidly determine particle size distributions of homogeneous and two-mineral materials in the 74-micrometer (200-mesh) to 7-micrometer size range. The system is based on the elutriation and sizing of particles by hydrocycloning techniques and the sensing of particle weights by a gamma ray attenuation method.. Size distributions of three minerals (quartz, hematite, and magnetite) and a two-mineral combination were accurately determined by a prototype system. The analyzer system was found to predict individual fraction weights to within ±0.85 percent or better at a 95-percent confidence level using 25-gram feed samples of semiconcentrates from a taconite plant.