Table of Contents

The low cost of mining was the principal consideration, since, with mercury’s price per pound, the total gross value of the ore did not exceed too much per ton. Square setting and filling was out of the question, so various attempts with cheap methods were made, among them a shrinkage system. None gave satisfaction on account of the peculiar character of the ground. The mud rock being soft and slaky became easily dangerous and impossible to work.

The pay vein averages 20 ft. in width, and has its own local characteristics. The foot wall stands nearly vertical and is either serpentine or barren sand rock. The vein proper is a contact vein of typical “mud rock.” The first 10 or 12 ft., as a rule, is coarse, hard mud rock and contains cinnabar only; then comes from 7 to 10 ft. of fine, darker mud rock containing both native quicksilver and cinnabar; then follows a gradual transition of vein matter into barren mud rock. (See Fig. 1.)

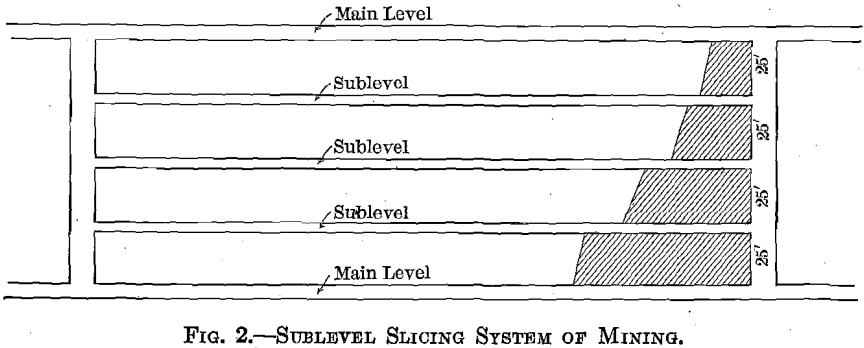

The method of mining locally employed is as follows: The whole ore-body between two main levels 100 ft. vertically apart, for a longitudinal distance of 300 or 400 ft., is attacked by two raises, which are connected by intermediate levels 25 ft. apart. (See Fig. 2.) Long holes are drilled with hammer drills from below and above on one end of the slice and shot. The slicing proceeds from one end of the block, and the ore is trammed to the other raise. Shooting from above and below at the same time, the intervening slice is completely broken up. What broken ore falls into the drifts is dumped into the chute; most of the ore is handled from the level below.

The cost of driving in the mud rock with hammer drills ranges from $1 to $2 per foot; and as the driving is done entirely in ore, the mining of the latter costs only from $1 to $2 per ton. Locally this has proved the most efficient and cheapest method that can be practiced without endangering the lives of the miners. If large pieces should come down they are easily broken up from below. The ground is ideal for hammer drills, which are used in both stoping and drifting.

Reduction

Two methods are employed for the treatment of the ore. Wet ores are first concentrated and then treated in the Scott furnace; but the dry ores are charged directly into the Scott furnace of the usual type.

The ore is crushed at the mine to about 1½ in. in diameter and brought to the furnace plant by a bucket tramway. The wet ore is fed by a Challenge feeder into a 3½-ft. Huntington mill provided with 16-mesh screen. Without settling the undersize passes directly to a Deister table.

Since the gangue is more friable than the ore, a Huntington mill was selected for fine grinding; and little sliming takes place. The charge contains about 0.3 per cent. Hg, or 6 lb. per ton, and the concentrates carry about 5 per cent. Hg, or 100 lb. per ton. From present results, the extraction seems to be 80 per cent, and the concentration ratio 20 into 1. It requires three men for attendance at $7.50 per 24 hr. and $2.50 for power, or a total of $10 for a capacity of 20 tons, or 50c. per ton. The concentration of the wet ore is successful at the Oceanic but more costly than direct furnace treatment. The concentrates are dried and then charged into the Scott furnace, but not into the retort, as this would prove too expensive.

Some experiments have been made lately with the flotation process on quicksilver ores, but it is hardly probable that this process ever will find application, for two good reasons: (1) The fine grinding alone would cost as much as the ordinary furnace process; and (2) the oil sticking to the concentrates would distill over in the retort and severely impair the quicksilver, which would have to be specially cleansed of its coating of oil.

The furnace plant at the Oceanic consists of a 50-ton Scott tile furnace, one brick condenser, and three wooden condensers. In the last two years’ operations many improvements have been made, among which are the automatic sealing of the charge; the reinforcing of the tiles; and radical changes in the firing and the system of condensing.

Charging

The old method provided for shutting off the ore a flat cast-iron gate, which caused endless trouble. The gases, being very acid, attacked the iron of the gate, which would not last at times more than two months, and its destruction would mean a shut-down. The escaping gases are very harmful to the men charging, besides being the source of considerable loss. Mr. Innes designed a simple and inexpensive arrangement, which served all purposes (see Fig. 3). Above the long charging

chute (which measures 9 in. at the bottom, above the first tiles, and 4 in. at the top), he placed a cast-iron spreader to trap the escaping gases, which are drawn off by a 6-in. cast-iron pipe into a special water-cooled wooden condenser. The spreader plates are made of cast iron, 18 in. by 1½ in. by 4 ft. long, and lie loose on an iron saddle, so that in case a bar has to be used, they can be turned back, giving full access to the throat. The opening on either side of the spreader is 6 in., but enough ore is charged to keep the spreader covered all the time. The sides of the spreader must be kept covered high enough to prevent the escape of gases. As the ore, after being burned sufficiently, is discharged below, fresh ore follows from above automatically. This method prevents sudden rushes and the even draft of the furnace is never disturbed—an ideal condition for good furnace work.

Reinforcement of Tiling

The Scott furnace, tiled and reinforced as described, has run for two years and has never given the slightest trouble. Not only are the tiles supported by fire brick, but also their end joints are covered with fire brick, which has a strong and steadying effect in case ore should be hung up and started again with the tickler through the pigeonholes. The tickler is a long iron rod with a jointed end, folding back in a certain position to start the ore again by moving it backward and forward. The tiles in a quicksilver furnace have to be handled with the utmost care, since, in case a lower tile should loosen and give way, the upper ones are apt to follow, causing a general shut-down of the furnace. The shutting-down of a Scott furnace is not like that of a smelting furnace, a question of hours or a day, but one of weeks, a very serious matter since production ceases entirely during this time. Hence the above details are very important to a practical furnace man and should be borne in mind.

Change in Firing

The system of roasting the ore has been changed to one of sublimation, or rather one of handling the furnace on the principle of a retort.

On opposite sides of the Scott furnace were fire boxes for burning cord wood on grate bars. The latter have been entirely removed and the fire boxes bricked up solid, just enough space being left on the extreme end for ashes to drop into the ash pit below. Ash pit and fire box are tightly closed; but enough air seems to enter through cracks to keep the wood in a state of glow. Formerly 2½ to 3 cords of wood were burned in 24 hr. on the same ore as at present, with a production of from 40 to 50 flasks of quicksilver. Now, less than ½ cord of wood produces not less than 100 flasks per month on a daily treatment of 50 tons of ore. These extraordinary results are easily explained. The mud rock contains considerable marcasite (FS2); and it was a great mistake to roast the ore until it had been burnt red. Plenty of air entered through the fire box and the pigeonholes, causing a much higher heat than was necessary, and also, by roasting all the marcasite, producing a large amount of SO2 and SO3 gases. The heat and draft made large amounts of soot of low value, keeping the retort going nearly all the month. At the present time the soot is cleaned up in a few days, and metallic quicksilver is recovered, which was lost before. No air enters the furnace except what leaks in at the bottom and through cracks in the fire box. The bottom of the fire box is sealed tightly, as are all pigeonholes. The temperature in the furnace is a dull red glow, and most of the time the burned ore is black, instead of red, as formerly. Pannings show no cinnabar; and the sublimation of the mercury seems to be absolutely complete. The assay of the ore, all the year around, does not seem to average more than from 6 to 7 lb., and assays I have made by means of the distillation method ran from 6 to 6½ lb. of quicksilver per ton. Assuming 6½ lb. as the average, the contents in a month’s run would be:

1,500 tons x 6.5 lb/75 lb. per flask = 130 flasks per month.

The average monthly output is about 110 flasks, and allowing for 8 flasks retained in the dust chamber, which is recovered only when the furnace is shut down, the actual extraction is

118/130 = 90.8 per cent.

This is an excellent extraction with the present condenser plant, and is principally due to the radical metallurgical change pointed out above.

The assay of ore so low in grade as the Oceanic offers considerable difficulties; and a chemist not familiar with mercury ores will have some trouble in checking results. Locally, the pan is generally used as the most expedient means, and with some experience differences in the grade of the ore are readily distinguished. This seems a crude way but it proves to be as accurate as is necessary. After having hundreds of samples run, there seems to be little difference in the grade from the different levels. The ore is pretty well disseminated in fine grains all through the rock, which looks like waste, very little cinnabar being visible to the naked eye. After moistening the rock little dots of ore may be seen here and there; but the mass hardly looks as rich as it actually is (carrying from 0.3 to 0.4 per cent, of quicksilver). The cinnabar is always bright red; but the native quicksilver is not always easily visible, particularly when the ore has been mined some time. The proportion of native to cinnabar is not known but on the whole the former is of minor interest.

Condenser Plant

The condensing system has also undergone an entire change during the last year. Formerly all condensers were made of brick, as was only natural, in view of the excessive heat developed. But brick is not a good material for condensers, being poorly adapted to withstand the corrosion of the gases and the use of water during cleanups—the latter hastening materially the deterioration of the brick.

By the time the furnace gases leave the cast-iron downtake and enter the fire-brick condenser, the temperature is hardly above 250° C. They enter the brick condenser at the top and are drawn off at the bottom, where the temperature has dropped to 170° C., and are then taken into the first wooden condenser, made of tongued and grooved redwood. This soon sweats out the pitch and seals itself tight, appearing as if it had been painted. Formerly divisions were built in the condensers and the gases were let in at the bottom to be circulated up and down; but this has been found less efficient than letting in the gases at the top and drawing off at the bottom. As long as the gases are warm, they have a tendency to rise, hence by drawing off at the bottom the coolest gas is taken. The tops of the wooden condensers are easily water-cooled. The condensers are square wooden boxes of the simplest construction, with a good, tight bottom. The gases have in them a chance to expand, cool through radiation, and gradually descend. This principle is followed through the whole condenser system. The redwood seems to radiate much better than brick, and easily withstands a temperature of 170° C.; so there is no reason for the use of brick, which is more expensive and less efficient. What brick condensers still remain at the Oceanic mine will be replaced by wooden ones as soon as the change can be made.

Many experiments have been made with all kinds of baffling, but without any success. A minimum amount of draft and maximum amount of expansion gives the best results. All fanciful apparatus with water-cooling or air-cooling pipes, etc., is simply worthless and expensive. The flow of gases must be a slow one and all possible room for expansion must be given. No acid-proof mortar has been found to withstand the corrosion of the gases; but the redwood seems to fill all requirements. From the second (redwood) condenser, about 1,000 gal. of water run out daily. This is the condensed moisture of the ore. It is very acid and carries quicksilver in solution, which will be precipitated in future and may yield as much as a flask per month. I have no doubt that the extraction of quicksilver from this low-grade mud rock will eventually be brought up to 95 per cent., which certainly is a decided progress, when we consider that a few years ago the extraction hardly reached 50 per cent.

Costs and Profits

Since there is likely to be an increased demand for quicksilver in the future, the question naturally arises, What grade of ore can be profitably worked?

The size of ore deposit, cost of mining, wages, and fuel ought to be carefully considered before making the first outlay, which in the mining and reduction of quicksilver is not a trifling matter. An efficient 50-ton plant, with all accessories, will easily cost $25,000 or more; and there should be a considerable tonnage of ore in sight to warrant such an outlay of capital.

At the Oceanic mine the cost of mining is exceedingly low, for the reason that the vein is soft and easily stoped. Wages are low also.

Miners are glad to work for $2.50 per 8-hr. shift, on account of the low cost of living in a dairy and agricultural country. Wood costs $5 per cord, delivered at the mine.

The reduction costs for all furnace operations on 50 tons of ore daily are as follows:

Adding the handling of the soot in the retort, the total cost is about 50c. per ton of ore.

With a recovery of 91 per cent., or 5.91 lb. of quicksilver per ton, worth 50c. per pound, the value recovered would be $2.95 per ton, and the total cost would be ($1 for mining and 50c. for reduction) $1.50, leaving as net profit per ton of ore $1.45. This is but a small margin of profit, and it is evident that at the figures named, close management and a large tonnage of ore are necessary to make a successful business.

The use of quicksilver in the form of fulminate, containing 70 per cent., and as corrosive sublimate, containing 73.8 per cent., must be extensive and a further market advance may be expected. With such an advance, some revival in quicksilver mining may be looked for, particularly in California, where many abandoned properties exist. What can be done with low-grade quicksilver ores under favorable conditions, particularly with low mining cost, may be seen from the following description of the Oceanic mine, near San Luis Obispo, Cal. Its operations date back to 1876, when rich sand ores were discovered. In three years 7,400 flasks of quicksilver were produced, but since then the deposit has been worked only sporadically.

Until two years ago various attempts had been made by the Oceanic Quicksilver Co. to mine the more refractory “mud rock,” which was encountered lying beyond the “ sand rock.” Mud and sand rock in varying quantities were treated together, with poor results, but operations were successful with sand rock of fair percentage. About two years ago, when all the sand rock had been exhausted, Murray Innes purchased the Oceanic mine. He found large quantities of low-grade mud rock, varying from 6 to 8 lb. of quicksilver per ton, which at the prevailing low price of quicksilver demanded very cheap mining costs, in conjunction with high but cheap metallurgical extraction. At that time the extraction of quicksilver from mud rock ranged between 40 and 50 per cent., as far as I am able to learn.