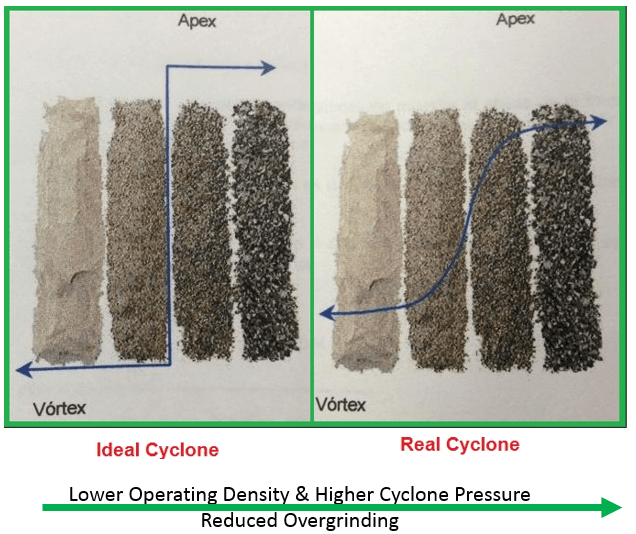

The Principle of Operation of Hydrocyclone is, in simple terms, the forces of gravity and centrifuge to separate large or heavy particles from smaller and lighter one. When sized correctly will “cut” like the ‘real cyclone’ below VS the imaginary ‘ideal’ one on the left.

Hydrocyclones are preferred units for sizing or desliming large slurry volumes cheaply and because they occupy very little floor space or headroom. They operate most effectively when fed at an even flow rate and pulp density and are used individually or in clusters to obtain desired total capacities at required splits. Sizing capabilities rely on centrifugal forces generated by high tangential flow velocities through the unit. The primary vortex formed by the incoming slurry acts spirally downwards around the inner cone wall. Solids are flung outwards by centrifugal force so that as the pulp moves downwards its density increases. Vertical components of the velocity act downwards near the cone walls and upwards near the axis.

The less dense centrifugally separated slime fraction is forced upwards through the vortex finder to pass out through the opening at the upper end of the cone. An intermediate zone or envelope between the two flows has zero vertical velocity and separates the coarser solids moving downwards from the finer solids moving upwards. The bulk of the flow passes upwards within the smaller inner vortex and higher centrifugal forces throw the larger of the finer particles outward thus providing a more efficient separation in the finer sizings.