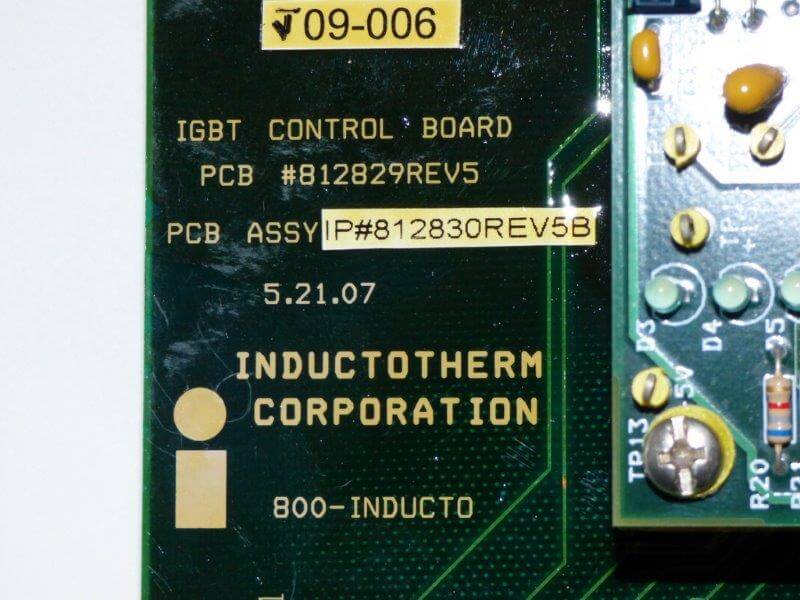

125kw Inductotherm VIP-I Precious Metals Melting System: The furnace was only used for proof of concept in a platinum recovery project and has extremely low hours. It is practically new… It is a top of the line, USA built, VIP- I Inductotherm system using their latest IBGT technology and was specifically designed to handle non-ferrous metals (gold, platinum, copper, brass, bronze, etc.) If stainless steel melting is required, it is very easy to make the modification with this unit. All drawings and manuals included. It was not used in a foundry application/environment and is exceptionally clean. It has multiple cooling and fail-safe systems to protect the furnace should there be a pump failure or power outage during an important melt/casting.

Asking price is $89,000. We can also supply installation support and operational assistance if requested.

Inductotherm 125kw VIP-I (Blue) – Very Low Hours

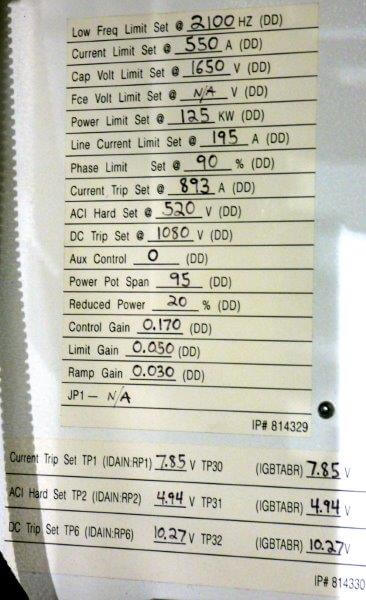

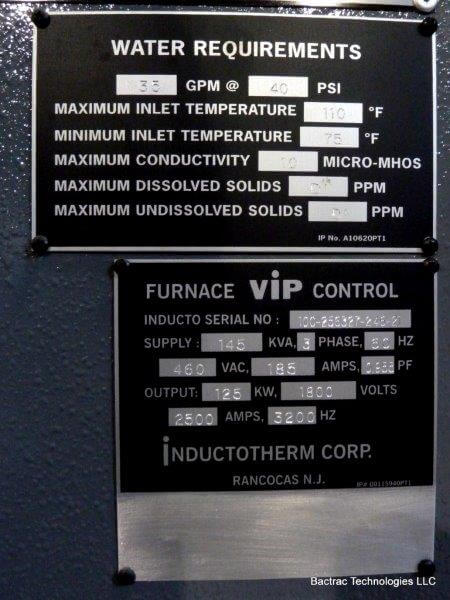

- Power Required: 460 Volt / Three Phase / 60 Hz / 145 kVA / 185 Amps

- Output: 125 kW / 1,800 Volts / 2,500 Amps / 3,200 Hz.

- Circuit Protection System

- Safety Isolation Transformer

- Ground/Molten Leak Detector

- NEMA 12 Combination Electric Starter

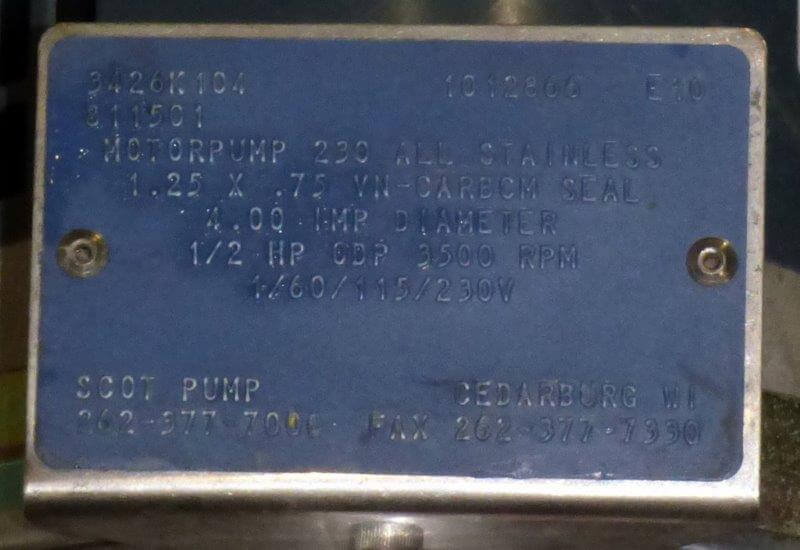

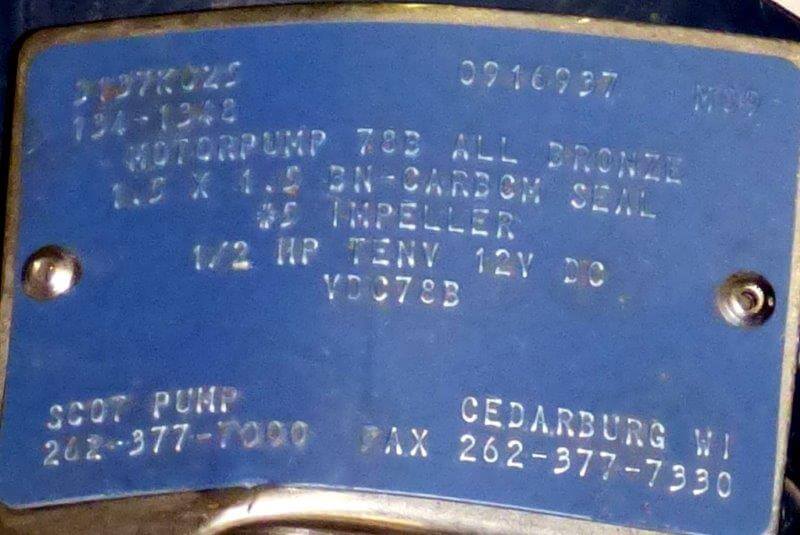

Separate External Closed Water Cooling System

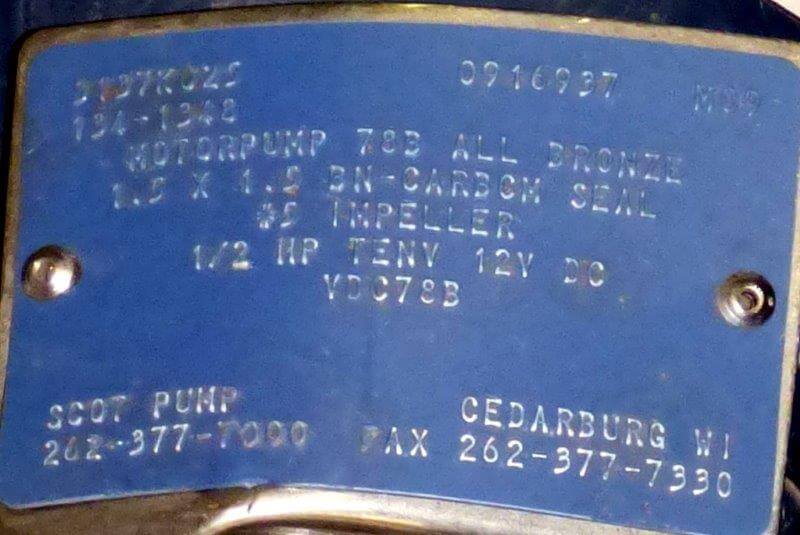

- Redundant Dual Coolant Pump Module/Skid (Twin Pumps)

- Separate Cooling System Electrical Control Cabinet

- Automatic DC water pump in the event of a power failure (with Battery Back-up and Emergency Lights)

150kg (300#) Dura-Line Model 500 Furnace Assembly

- Integral Fume Ring

- Integral Hydraulic Tilt Cylinders and Control Valve

- Heavy Wall Copper Induction Coil

- Leak Detection Assembly

- Stanchion Insulation

- Water Cooled Power Leads

Electric Powered Hydraulic Pump Unit

- Pump / Motor

- Pressure Relief Valve

- Pressure Gauge

- Return Line Filter

- Reservoir

- Manual Motor Starter

NOTE: We also have a custom engineered, heavy duty, two-level superstructure for the furnace. The elevated platform gives you a large work area to perform traditional “floor-level” castings with removable floor panels that allows you the flexibility to perform very large, tall or odd-shaped castings.

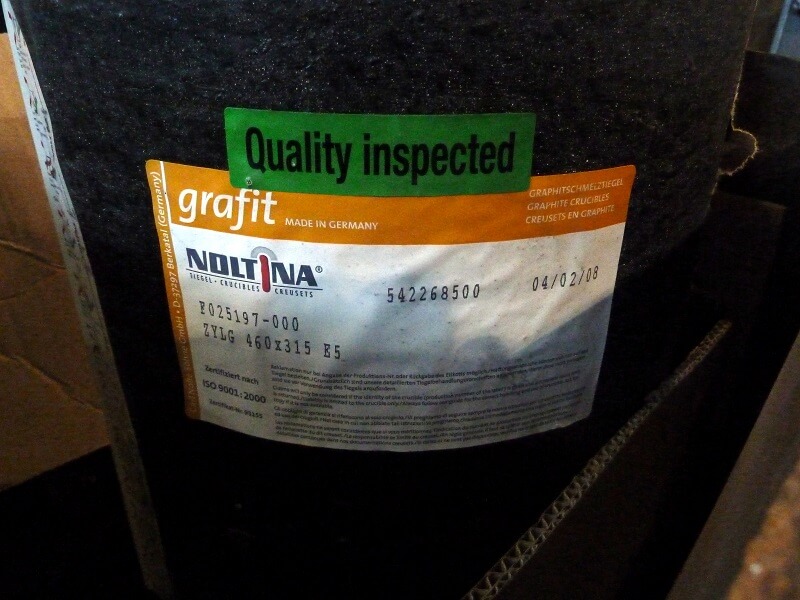

Noltina‘s Grafit crucibles are physically formed CLAY-GRAPHITE crucibles characterised by high refractoriness and good thermal conductivity as well as very good thermal shock resistance and chemical resistance against fluxes. In order to meet the specific requirements of induction furnaces, NOLTINA has developed a specialised range of CLAY-GRAPHITE crucibles with a specific modified electrical resistivity. This optimises the coupling power of the crucibles especially in middle frequency induction furnaces (Frequence 1 kHz – 3 kHz) and avoids the risk of overheating.