Table of Contents

Pre-concentration by sorting is as old as the mining industry. Inevitably waste rock is broken with ore. Separation may take place in the stopes by selective mucking and transport, or selective loading and transport of ore and waste by 12-cu. yd. shovels and 100-ton trucks in large open pit operations. Hand sorting of 1″ to 16″ pieces, formerly widely practiced at underground chutes and prior to or following first stage crushing, has greatly diminished in the United States with its high per hour labor cost, although still widely practiced in other countries and, surprisingly, in some of the most modern mills where inexpensive labor is available.

While the human can assess and compare specific gravity, color, lustre and texture together as an ore picker, machines have very limited scope because receptors as efficient as the eye and assessors as efficient as the brain have not been constructed. Photo multiplier tubes and solid state detectors teamed with solid state data processing systems have advanced greatly in the last few years and mechanical sorting begins to become practical for some ores.

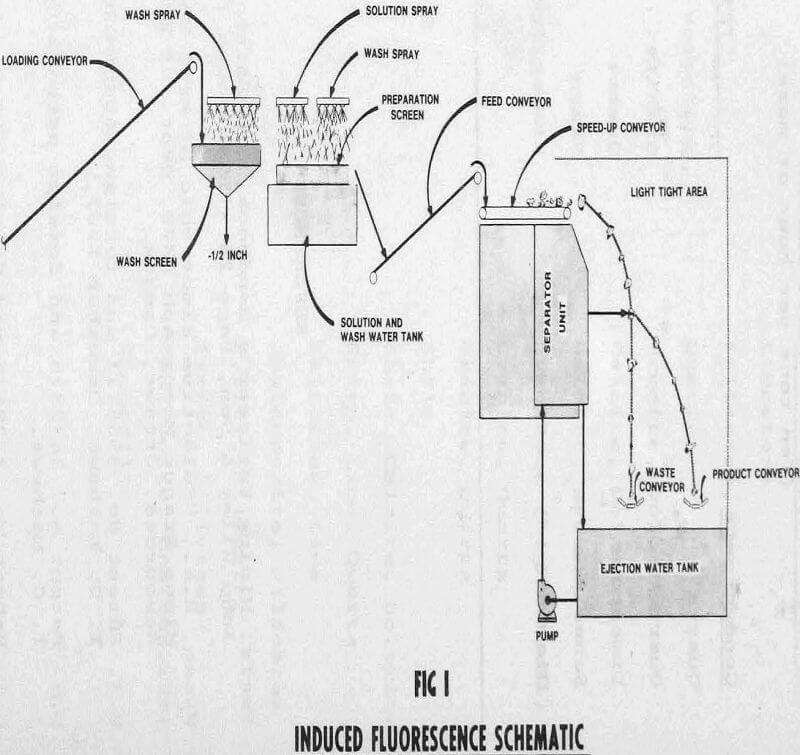

The phenomenon of fluorescence is particularly adaptable to separation processes since the rise time of energy as photons is measured in fractions of microseconds and the energy packet is large. The fluorescent wave length differs from the radiation wave length. Color of the mineral and reflectance of incident radiation do not affect the system. Laboratory and pilot plant work reveal that it is possible to preferentially coat, and subsequently separate, any combination of minerals including silicates one from the other. Inexpensive reagents have been found with very low consumption per ton.

Physical separation is performed on the particles while in free fall at the end of a conveyor belt. Water jets are turned on at the appropriate time to meet the falling particles and drive them across a barrier which divides the free falling particles from those acted upon by the water jets. The large particle separator, which handles a mixed feed of sizes from ½” to 8″, has a belt speed of 200 feet per minute with 3/8″ water jets and 80 lbs. per square inch water pressure. The trajectory curve is a constant, determined by belt speed and gravity, therefore particle position is predictable for any time interval.

The capacity of the system is determined by the average particle size and the speed of the belt, which in turn is limited by the cycle time of the water jets. A turn-on or turn-off time of 3 milliseconds has been achieved with 3/8″ jets at 80 lbs. per square inch. If the minimum particle size is ½”, events can occur 12% milliseconds apart at a belt speed of 200 feet per minute. The cycle is thus 3 milliseconds turn-on, 6 milliseconds on-time, and 3 milliseconds turn-off. Belt speeds of 400 feet per minute are practical with particles of 1″ minimum size.

Photometric Sorting of Ore

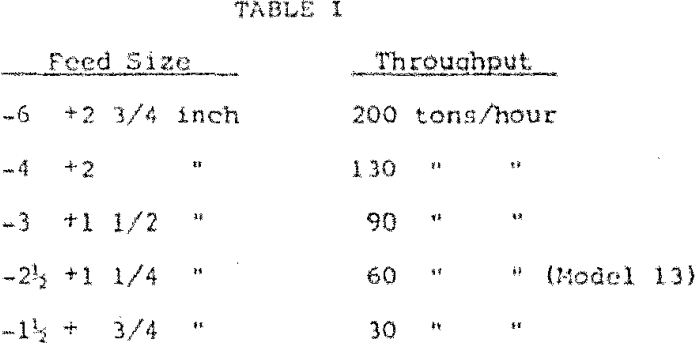

A laser light source and sensitive photomultiplier are employed in a scanning system to detect light reflected from the surfaces of rocks passing through the sorting zone. Electronic circuitry then analyzes the photomultiplier signal, which represents the varying intensity of the reflected light, and produces control signals to actuate the appropriate valves of an array of air blast rejection devices to remove from the feed certain particles selected by the analyzing process. Typical throughput per machine ranges from 50 tons/hour for a-2½” +1¼” feed to 200 tons/hour for -6″ +2 ¾” material.

Hand sorting of ore, based on human visual examination of the ore, is by no means new. This method of upgrading mine output is a practice still followed today even in certain high tonnage situations. More recent times have seen the successful installation of mechanical sorters capable of performing sophisticated analyses of ore particles at rates of throughput consistent with today’s mine outputs.

The Photometric Sorter separates rocks into two categories according to light reflectance properties. The “accept” category, in the case of the Doornfontein machine, includes those rocks having white or grey quarts pebbles in a darker surrounding Matrix, which have to be recognized by the machine as reef, while the “reject” rocks are either quartzite ranging from light green through olive-green to nearly black or tuff which is black, and has to be recognized as not being reef. These distinguishing optical characteristics are typical of the gold ores occurring on the Witwatersrand in South Africa. This sort is based on the knowledge that gold occurs mainly in the rocks which are recognized in the accept category. The sorter is calibrated for the type of ore feed, and may have to be recalibrated should the characteristics of the feed change, as does happen when mining moves to new areas and reefs of a mine.

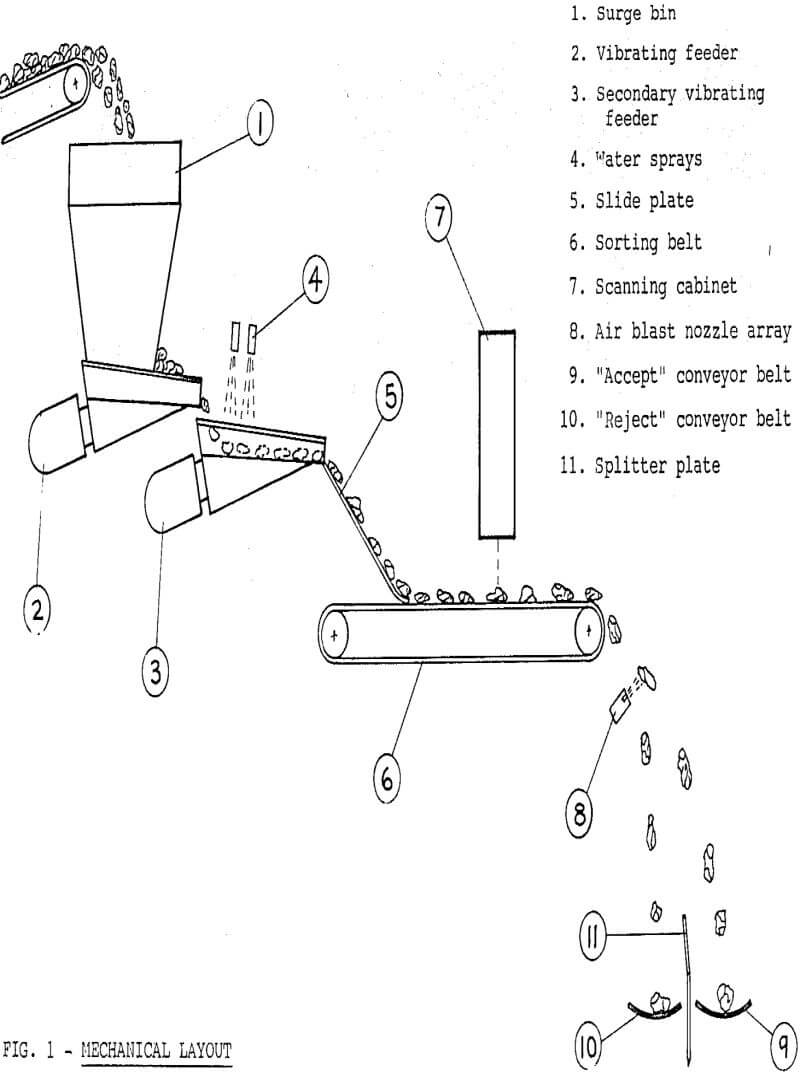

Presentation

Proper feeding of ore to the sorter is critical for optimum metallurgical results. Overfeeding causes excessive particle crowding and doubling up in the sensing-separation zone, adversely affecting separation efficiency. Underfeeding does not appreciably increase machine efficiency but does decrease the capacity of the machine.

Clean washed feed should be correctly sized to the specifications for which the machine has been designed. The presence of excessive undersize in the sorter feed decreases the capacity and efficiency of the machine.

The two main requirements in feeding ore to the sorter, namely:-

a) controlled feed rate; and

b) one-layer deep presentation to the slide plate are obtained by the use of a tandem vibrating feeder assembly.

The slide plate imparts acceleration to the particles of ore thus increasing their relative spacing. The bottom of the plate is curved to provide a direction transition from 45° downwards, to the horizontal plane of the belt surface. Ideally particle speed at the bottom of the slide plate and belt speed should be closely matched to have a minimum of movement of the particles relative to the belt surface as they land on the belt. Any movement on the belt tends to lead to touching and inefficient sorter operation.

This is a white PVC three-ply endless belt driven from the head pulley and with a crowned tail pulley. It is supported at 4 inch intervals by idlers to maintain it on a constant plane. It serves to present the rocks to the scanning zone in a stable manner, at constant speed and against a uniformly light background. The belt is kept clean by means of a mechanically driven scrubber brush.

Signal Processing

The video signal from the photomultiplier, together with certain timing signals also derived from the scanning system, and another timing signal picking up conveyor belt speed is applied to the electronics unit. The video signal is amplified and stabilized so that it will be unaffected by changes in the operating environment such as temperature, power supply voltage, and laser light power output.

Comparison of the instantaneous value of the video signal to certain preset reference voltages is performed to determine:-

- the presence of rocks in the scan; and

- such quantities as:

a) those portions of rock which are darker than a certain reference level; or

b) the occurrence of a change in the signal which represents the transition of the scan from one point on a rock’s surface lighter than a first reference level to another point darker than a second reference level. (It is typical of Witwatersrand ore that gold occurs around light pebbles in a dark matrix.)

The sorter can be programmed to evaluate individual particles on the basis of, for example:-

a) the percentage of the total observed surface area which is darker than some predetermined reference level; or

b) the average number of transitions from light to dark or dark to light areas, per unit of surface area; or

c) combinations of these and similar derived parameters.

Separation

The channel blast slots (blast manifold) are located downstream from the scanning line and below the head pulley of the sorting belt. Particles pass in free fall over the blast manifold.

Correct adjustment of the blast manifold is critical for achieving the co-ordination of the full air blast with the arrival of the accepted particle in front of the blast slot. Improper timing of these events will cause “premature” or “late” blasting. The time at which a valve opens and the time for which it remains open is controlled by the electronic circuitry.

The blast valve unit is composed of two elements, consisting of a pilot valve and the main valve, each operating on separate, independent air supplies. Pilot air pressure is maintained at a differential of 5 to 10 psi higher than the main air supply to assure positive valve functioning. The pilot valve, a 3-way normally open Valvair solenoid type, controls the release of the main air diversion blast.

Virtually all maintenance was performed on a planned schedule without interruption, to production, requiring the attention of one mechanic on one 8-hour shift per week. Plant availability of the sorter for the entire operating period amounted to 97 percent. Another 4 percent of time was lost due to factors outside the sorter, such as electric power supply, compressed air, modifications to plant affecting feed arrangements, etc.

As a result of the reef picking operation described above, some 31 percent of the run of mine material was being sent to the storage dump, and the mill feed was upgraded from about 0.32 oz per ton to roughly 0.45 oz/ton. The tonnage to be milled was reduced from approximately 169,000 to 116,000 tons a month. The reject material sent to the storage dump (about 53,000 tons per month) at 0.055 oz/ton of gold contained about 5 percent of the gold in run of mine material. Taking into account the capital cost of a milling plant and the operating costs, it was uneconomic to treat the reject at the $35 per ounce gold price prevailing during the sixties. It was regarded as material which would be treated at a later date when the economic picture changed and/or mill capacity became available.

The sorter feed consists of a screened fraction of the discard material from the existing reef picking plant in the -2 +¼” range. Thirty-two percent of this original discard tonnage, containing 45 percent of the gold discarded, and running at 0.08 oz/ton falls into this fraction, which is now sent to the sorter. (The +2″ material is subjected to a further hand sorting operation, which recovers a further small but high grade tonnage of ore, and the -1¼” material, consisting mainly of pieces of + 1½” rocks that have been broken by further handling, is added to the rod mill feed.)

During the period when there were no difficulties with air pressures 81 percent of the gold in the sorter feed was recovered. Bearing in mind that the waste rock mined above or below the Carbon Leader Reef contains a small quantity of gold (on average 0.005 oz/ton), this 81 percent is in fact a recovery of 86 percent of the gold in the reef discarded from the main plant in the size range considered. Overall the operation has resulted in an increase in recovery of 1.7 percent of the gold in run of mine feed.