Operating geology may not seem as exciting and glamourous as exploration, especially to recent graduates, but it has its advantages as listed below:

- Stability: Exploration is generally the first activity curtailed in recessive periods.

- Satisfaction: The results of good work are visible sooner and more often.

- Family life is relatively normal.

Geological work at an operating mine deals with basic data and may be divided into the following four categories:

- Recording (mapping, logging, sampling).

- Posting (plans, sections).

- Interpretation (projection, descriptive geometry, computer modeling).

- Effectively “selling” your interpretations to management (development headings and/ or drilling, avoidance of incompetent ground, locating ore, etc.).

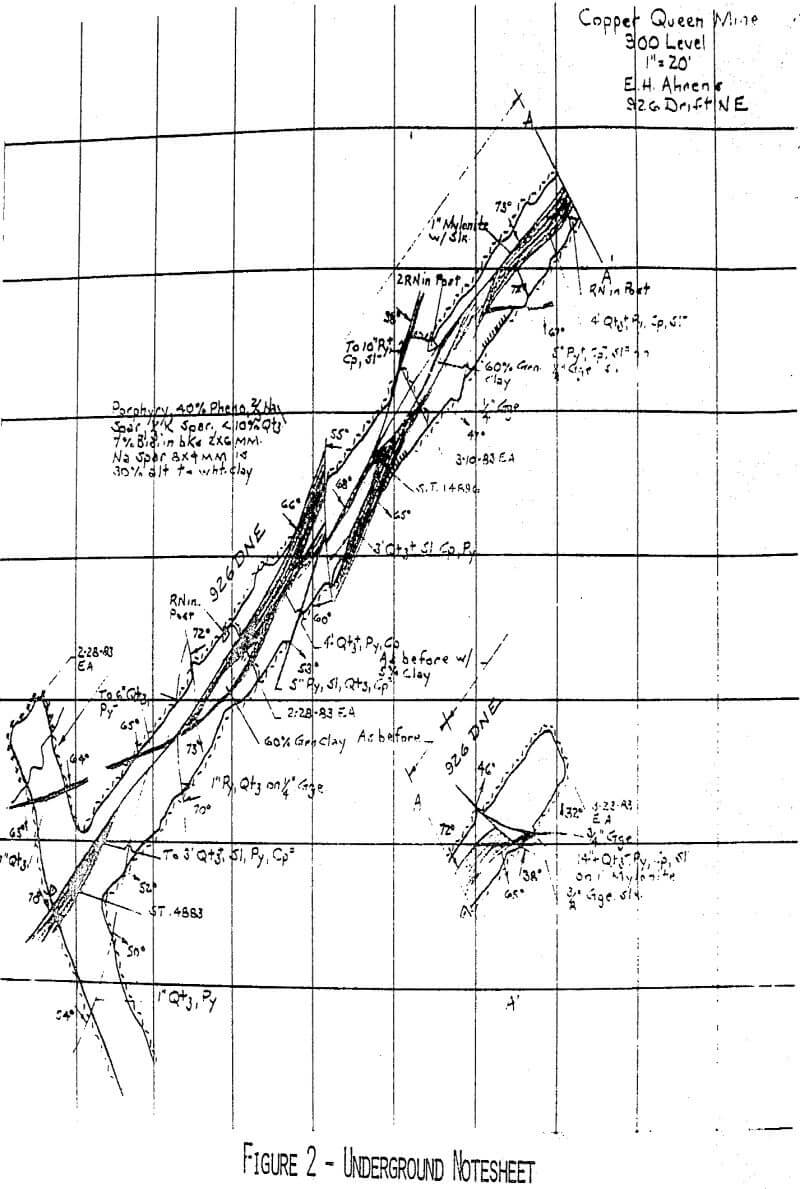

Procedure for Mapping

The following data are recorded by noting rib location normal to the tape (the Brunton should never be used to determine strike in a mine).

a) Faulting – properly weighted to indicate magnitude of movement (the amount and type of gouge is strongly influenced by rock type and/or pre-fault alteration).

b) Mineralization

c) Rock type (employ a continuous, rather than spot, description).

d) All notes are horizontal – light guide lines should be drawn and erased later.

e) Dip symbols should employ arrowheads three times as long as they are wide at the base and closed. All dip symbols should be of equal length.

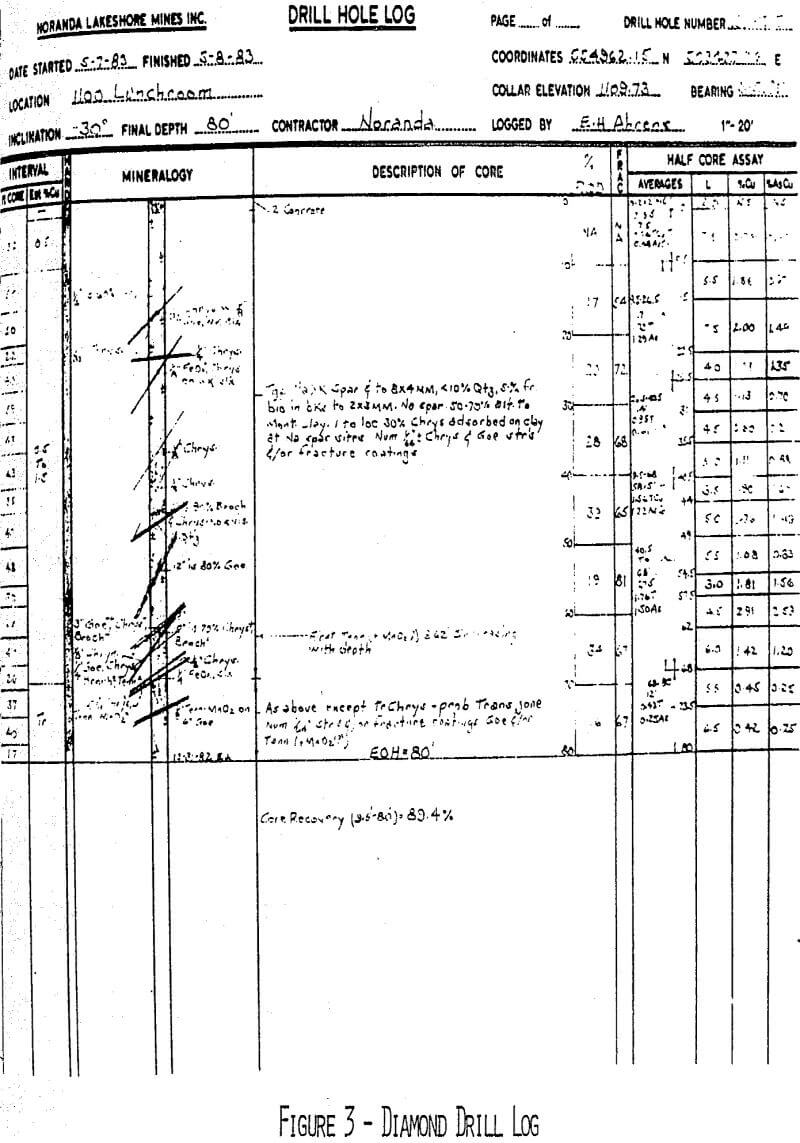

The objective is to record as much information as possible commensurate with practicality and expense. Diamond drilling is costly and core should be logged by experienced, competent, geologists. Unfortunately many consider logging tedious and/or boring and have a tendency to delegate this important work to inexperienced (and frequently inadequately trained) members of the staff. This can result in chaotic data.

Please note the following features is an example of a “single column” diamond drill log:

- Heading (note originators name).

- Scale

- Core size

- Core recovery

- Estimated percent copper

- Hardness

- RQD (or “BQD”)

- Fracturing

- Faulting (note variation in weighting)

- Quality of core angle

- Assays

- Notes – e.g., why a fault?

Sampling

A mylar advance sheet showing advance (and footage sampled) is maintained.

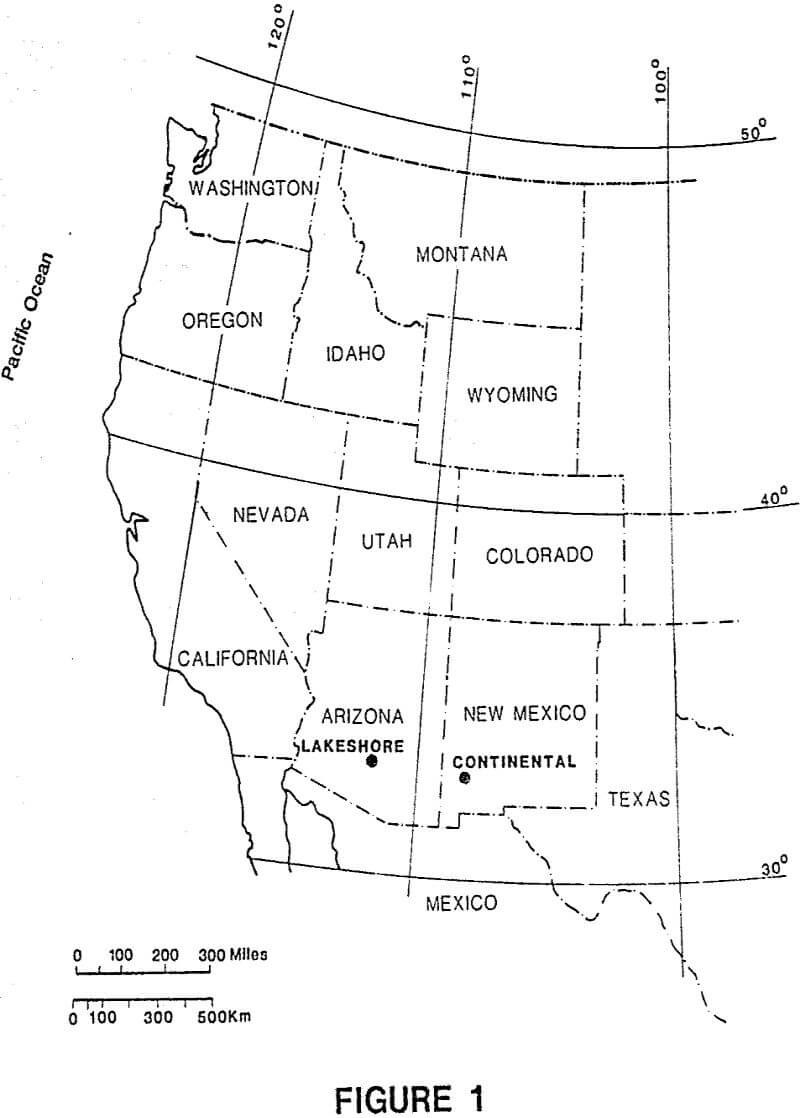

The sampling technique employed will depend on the amount and value of the element being assayed as well as the projectability of values. The Anaconda style chip method has proven satisfactory at Butte, Continental and Lakeshore. This consists of gathering 30+ pounds of evenly distributed chips (taken with a two pound hammer) from five feet of rib or face.

Assaying

Assaying is usually done under the supervision of the Chief Chemist but the accuracy of the data must be acceptable to the Chief Geologist. To reiterate, the accuracy required will be determined by such parameters as the value of the mineralization, grade project-ability of assays, cost, speed of analyses, etc. Cooperation between the geological staff and the analytical section is mandatory.

Generally, relatively low-grade porphyry copper ores are assayed by atomic absorption (and less sensitive samples, such as draw control, by x-ray with frequent AA checks). X-ray analyses for copper is invalid if the iron content exceeds 10% or varies markedly. Pyrite is roughly 22% iron and high pyrite ores require the determination of iron and the removal of its effect by calculation before copper values can be considered valid.

Structural Analyses

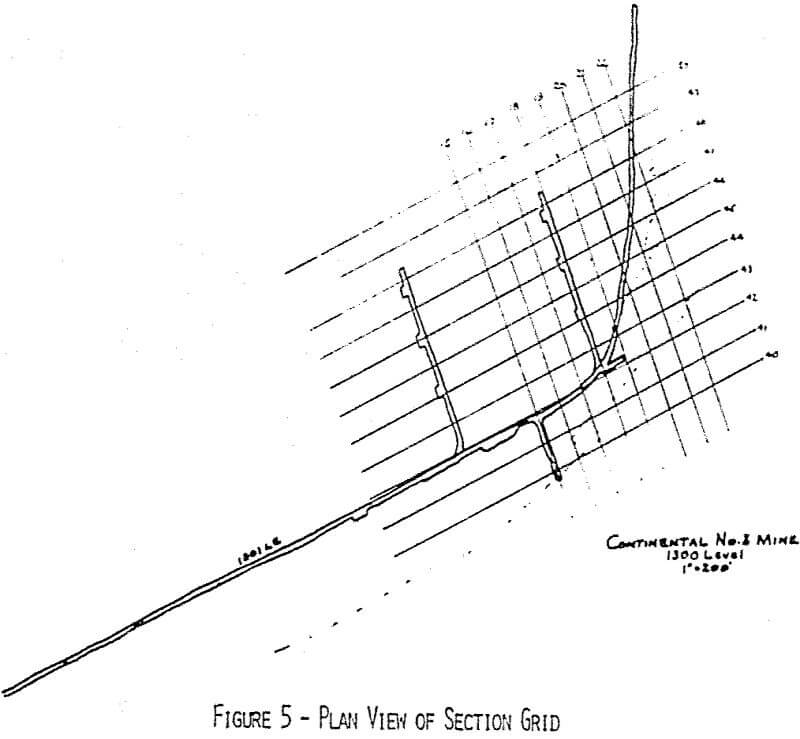

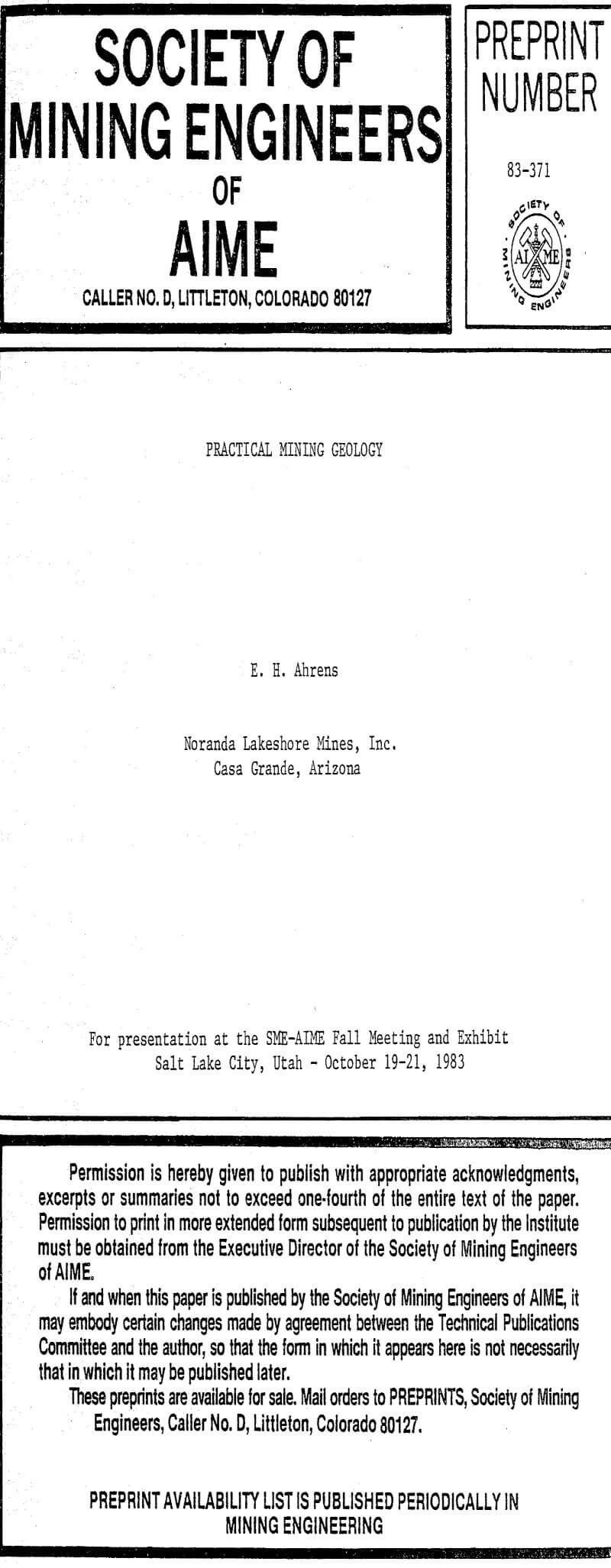

The method consists of a combination of cross and long sections with closely spaced plans. Geological data must check at all intersections and appear reasonable. When it does, it is generally accurate.

In the case of open pit mines, the end product is a set of median bench plans depicting:

- Rock type

- Alteration

- Ore (with grade)

- Resistance to stripping or mining (i.e., hardness, fracturing, etc.).

- Location of any material having an adverse effect on milling and recovery.

Be a Geological Watchdog

Keep your mine out of trouble by identifying incompetent ground (i.e., rock requiring expensive support and/or costly maintenance).

Example: 200 level north main haulage at Lakeshore: Management was strongly advised against a proposed drive through approximately 800 feet of extremely incompetent granodiorite porphyry overlying the tactite horizon. This was to be main haulage and since plans were to produce through it constantly, no time for maintenance existed. A revised course through better ground was proposed and accepted. The heading was so driven and stayed in good rock resulting in:

- More rapid advance

- lower costs

- Greater safety

- Cheaper support (held with rock bolts rather than expensive steel sets).

- An almost maintenance free haulage.