Well-Known throughout the world for finest mill equipment, we, nevertheless are very active in the development and construction of placer machines of various types and sizes to meet every need.

A prime essential for making money in a placer is high yardage, and equipment to handle it must be put to work as soon as preliminary testing indicates that the extent and value of the ground warrants such an investment.

Innumerable local conditions will govern the design of the plant, and therefore the placer operator will find the facilities and experience of Equipment Company of the greatest benefit in the interpretation of these conditions and the solution of particular operating problems with which he is confronted.

With the rapidly increasing use of the (Selective) Mineral Jig comes a new era in the design of these plants. Due to the proved, efficient action of this machine, a much greater capacity can be obtained from the same size plant (and investment) and the plant can get in more productive operating time because the jig provides an entirely continuous operation without stops for clean-ups. Furthermore, the jig makes a higher recovery by saving fine material which previously was not recoverable.

Illustrated above is such a plant mounted on pneumatic tires for dry land operation, although flanged wheels for rail transport or steel drums for timber runways can be used instead where this may be desirable. The operation is as follows:

Gravel or sand excavated by tractor shovel, drag-line or scraper bucket from the placer deposit is discharged to the top of the grizzly. Oversize rocks and pebbles roll off the grizzly to the ground.

Undersize material, 2, 3, or 4 inch diameter, falls through the grizzly to a hopper under the grizzly. Under the hopper is a feeder equipped with a heavy rubber belt and having an adjustable stroke which delivers the gravel to the revolving scrubber-screen.

Wash water is delivered to the feed end of the revolving scrubber-screen and also to outside of revolving screen.

Oversize material from the revolving screen falls to a portable rubber belt conveyor stacker which elevates it to the tops of the tailing piles.

The undersized gravel, falling through the openings of the revolving screen, flows to the (Selective) Mineral Jig which recovers coarse and fine gold particles, together with the black sand particles, in the hutches in the form of a clean, high grade concentrate.

The tailing from the jig flows to a riffled sluice which serves to recover any gold which may have escaped because of surges or irregularity in the feed to the (Selective) Mineral Jig.

Since the grizzly, feeder, revolving scrubber-screen, (Selective) Mineral Jig, gasoline engine, and transmission equipment are supported on a structural steel frame; the portable plant may be moved forward to be within reach of the excavator digging bucket as the excavator proceeds.

However, since the unit illustrated was designed for one particular set of conditions, it may not be the answer to your problem. Let Equipment Company design and build your placer plant to suit your specific requirements and thus ensure highest economic return.

More complete information can be obtained by writing any Equipment Company office.

Placer Unit, Trommel-Jig

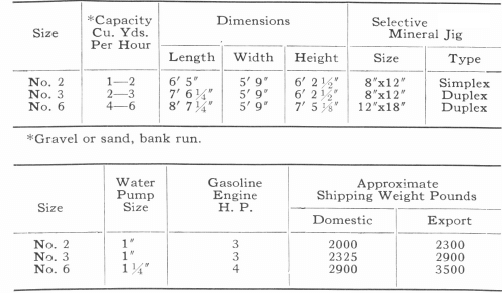

Trommel-Jig Placer Unit is driven by a gasoline engine or electric motor which also drives a centrifugal water pump, furnishing water for washing in the trommel as well as for use in the operation of the (Selective) Mineral Jig. A rubber suction hose, reinforced with steel wire coils which are imbedded in the walls of the hose, and a foot valve, are furnished.

The entire unit is mounted on a steel base with steel sides for easy transportation from place to place, and the trommel and jig are supported on a structural steel frame which carries necessary shafting and belting, making the unit completely self-contained.

In operations where the Trommel-Jig Placer Unit is used for the recovery of gold from gravels, the black sand values which are concentrated in the jig hutch can often be reground and amalgamated with minimum effort and at lowest cost by means of the Amalgamation Unit. This unit, when followed by the Amalgam Separator, makes possible the efficient production of an amalgam ready for retorting to bullion.

In many placer deposits the values are associated with clay or cementing materials and with masses of black sand. In order to secure concentration of the mineral particles, both coarse and fine, it is necessary to thoroughly disintegrate and wash the gravel. The material to be treated is shoveled or dumped into the large feed hopper and then is fed regularly into the washing and disintegration section of the rotating trommel. This disintegrating chamber is equipped with spiral lifting blades which elevate and mix the gravel several times during a revolution. Water is added at the feed end of the machine and the action secured by the lifting blades breaks up the lumps of cemented or clayey materials so that the desired minerals are freed and separated.

The material then passes on to the screened section of the trommel for the removal of the washed large particles from the undersize. This screening section includes an inner screen made of steel plate having rectangular openings. Surrounding this heavy perforated plate is an outer replaceable screen of 3, 4, or 6 mesh steel wire screen, depending upon the character of the material being treated. The washing action is continued in this screening section so that the oversize material is discarded at the end, thoroughly washed and free from any adhering valuable particles. This is particularly important in placer operation.

The material which goes through the screen is caught in a hopper and passes to the (Selective) Mineral Jig which effects a selective gravity concentration, separating the heavy particles from the light gangue. The (Selective) Mineral Jig is a complete self-contained unit that can be operated with minimum water, requiring only one-half as much water as other types of jigs.

More complete information can be obtained by writing any Equipment Company office.