A Plugged Chute Detection Probe is an emergency switch that will shut down the equipment should a transfer chute “become plugged. There are two common types of probes, a TILT SWITCH and a CONDUCTIVITY switch.

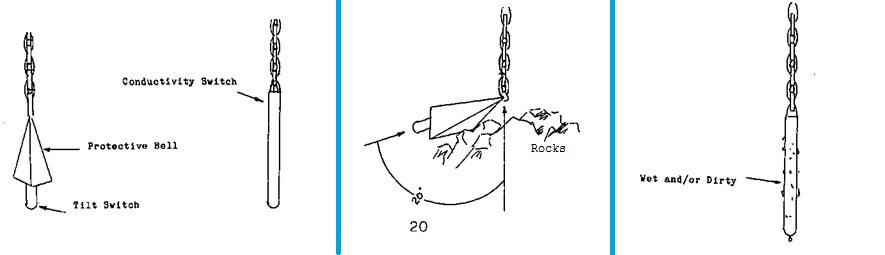

A tilt switch hangs inside the chute. If the chute plugs, the ore will build up to the switch. The placement of the switch in the chute is situated so the ore has to push the switch out of the way as it fills up the chute. When the ore tilts the switch past twenty degrees the switch will shut everything down. There are two things to watch for with this type of switch. First that fine material doesn’t build up around it. To work, the probe must hang free. Secondly it should be checked every so often to be sure that it is working. The design of the probe often incorporates a BELL around the probe to protect it but a wire may break or the support electronics may fail.

A CONDUCTIVITY switch is much like a tilt switch in the fact that it hangs inside of the chute and it takes contact with the ore to activate it. The difference is instead of the switch tilting, the contact with the ore completes an electrical circuit and shuts the equipment down. This type of switch can only work where there is a characteristic of the ore that allows it to be an electrical conductor. This may simply be moisture or a mineral that is in the ore. Because of the conductivity a dirty or wet probe may indicate a plugged chute where none exists. To correct this is only a matter of wiping the probe off with a rag.

A CONDUCTIVITY switch is much like a tilt switch in the fact that it hangs inside of the chute and it takes contact with the ore to activate it. The difference is instead of the switch tilting, the contact with the ore completes an electrical circuit and shuts the equipment down. This type of switch can only work where there is a characteristic of the ore that allows it to be an electrical conductor. This may simply be moisture or a mineral that is in the ore. Because of the conductivity a dirty or wet probe may indicate a plugged chute where none exists. To correct this is only a matter of wiping the probe off with a rag.

There are other types of probes that can he employed using light or sound to deactivate the equipment. They are either expensive or, as in the case of using light, subject to interference from dust.