A unique type of grinding mill liner has been developed by Waagner-Biro A.G. of Austria. This liner system, termed an angular spiral lining (ASL), was successfully tested by Magma Copper Company’s San Manuel concentrator in both their 10 Ft x 10 Ft (3.05m x 3.05m) and 12 Ft, 6 In x 14 Ft (3.31m x 4.27m) grate discharge wet grinding ball mills. Magma Copper’s savings in power and grinding balls justified conversion of more than half of their twenty-six ball mills to the ASL system.

Day shift samples were taken of each ball mill new feed, ball mill discharge, cyclone underflow, and cyclone overflow. Percent solids and screen analysis were determined on each sample. Computer tonnage and power consumption, for the same time period as the sampling, were also obtained. This sample period data was later accumulated for comparison with monthly records on production rate, power and ball consumption.

The original set of ASL liners was tested for nearly four months. Variations were made in the following items during this testing:

- Cyclone apex size

- Cyclone feed pump speed

- Mill discharge sump level

- Number of cyclones

- Ball mill discharge percent solids

- Cyclone feed percent solids

- Ball charge level

- Ball mill pulp level

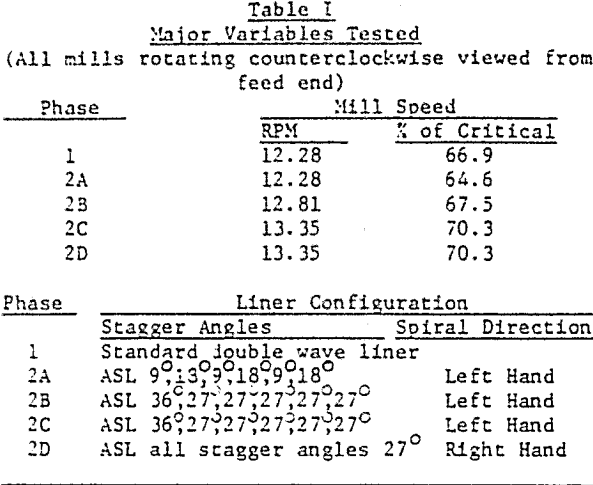

With the ASL mill at increased spaed and with stagger angles increased between liner rings, resulted in some improvement in both throughput and power consumption. However, those items were still on the unfavorable side.

A further increase in ASL mill speed, Phase 2C, resulted in 12.5 to 15.7 percent power advantage for the ASL system. Tonnage and ball consumption also showed improvement, however tonnage was still on the negative side. While these improvements were encouraging they were not significant enough to warrant duplication of the same configuration for further testing.