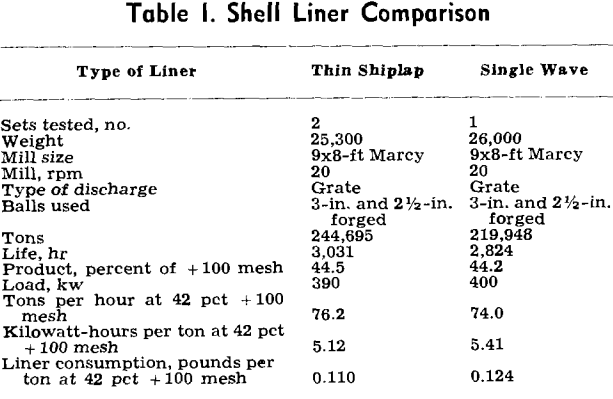

Grinding Practice—These tests were run in the 9 ft diam by 8 ft long grate discharge ball mills at Climax. Each mill functions in closed circuit with a 78 in. Akins duplex high-weir classifier, and a circulating load of 300 pct is maintained. The size of the mill feed is 6 pct on 3/8ths, which is ground to pass 28 mesh.

Testing Methods—Each grinding section is equipped with a conveyor scale on the ball mill feeder belt, a watt-hour meter on the ball mill motor, and an automatic sampler for the ground product.

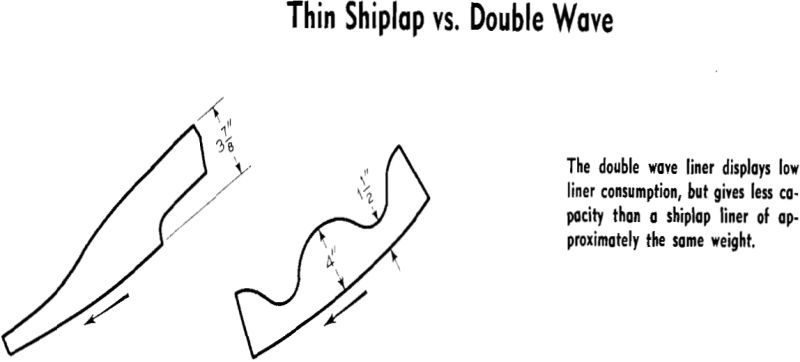

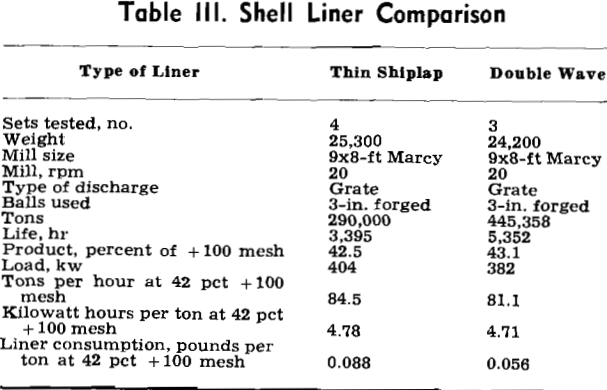

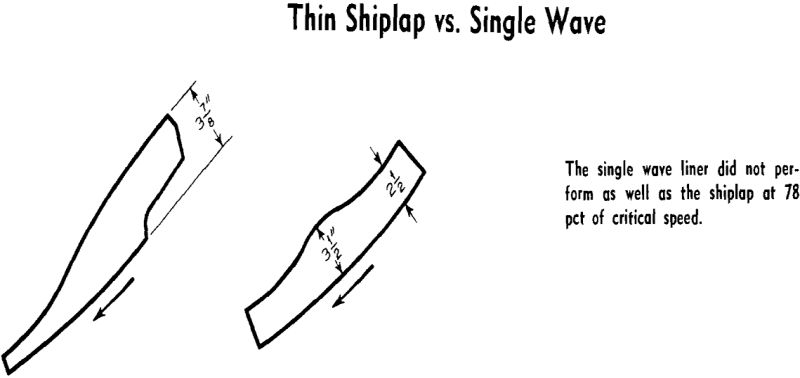

This test compares the shiplap liner to a single wave liner of approximately the same weight. The single wave liner did not compare very favorably with the shiplap at 20 rpm. It probably did not have a high enough lift for this speed. In more recent tests at higher speeds, the single wave liner has equaled the thin shiplap.

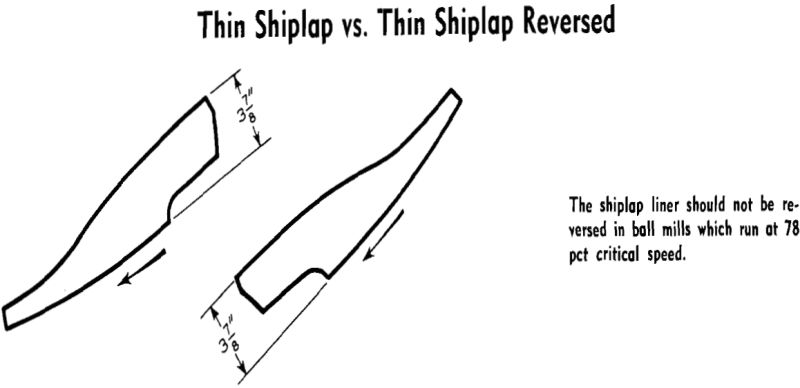

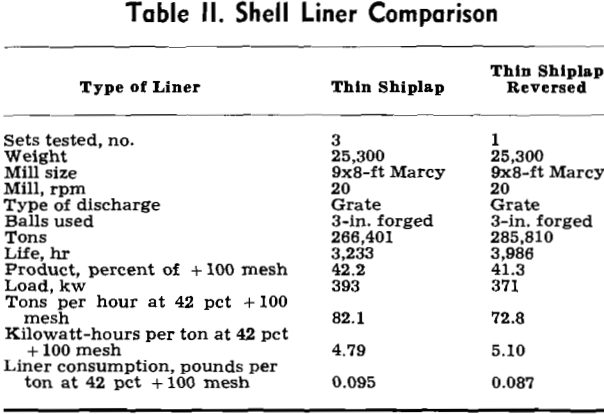

This test reveals what happened when the shiplap liner was put in backwards. The mill capacity was reduced by 11 pct and the power efficiency was lowered by 6 pct. The overall cost was high when the liner was used in this manner, even though the liner consumption decreased.