The Bakstad’s Patented Multiple Jaws, is a Jaw Crusher that represents the first real advance made in increasing the crushing range of jaw crushers since their introduction. This Is the only crusher designed to give you a primary and two secondary crushers in one unit. Crushers of the jaw principle type have conclusively demonstrated their superiority over other type crushers through fifty years of successful performance. The proven principle of the jaw crusher has not been deviated from in the design of the Bakstad Patented 3-Jaw Crusher. The Bakstad differs only in its crushing range, and here it is truly different.

Like using Jaw Crushers in Series

A Wider Range: Without sacrificing capacity the Bakstad Crusher will reduce rock in one operation to a product twice or three times as fine as that obtainable from any ordinary single unit crusher of the same size receiving opening. For example, a Bakstad Crusher capable of receiving 12 inch rock in its smallest dimension will produce as much 1 inch product as a single jaw crusher unit would of 2 inch material. Or it will turn out a product which will pass a 1/2″ inch screen ready for the pulverizer. Or it will turn out twice as much 2 inch material as an ordinary jaw crusher of the same size receiving opening.

That is what is meant by greater usefulness and lower costs. The three jaws in one do not mean that the Bakstad is useful only for fine crushing. It means likewise that double capacity is obtainable for products which might ordinarily be reduced by a single jaw crusher. The reason for this increased capacity is due to the fact that the Bakstad has twice the area of outlet found in ordinary jaw crushers.

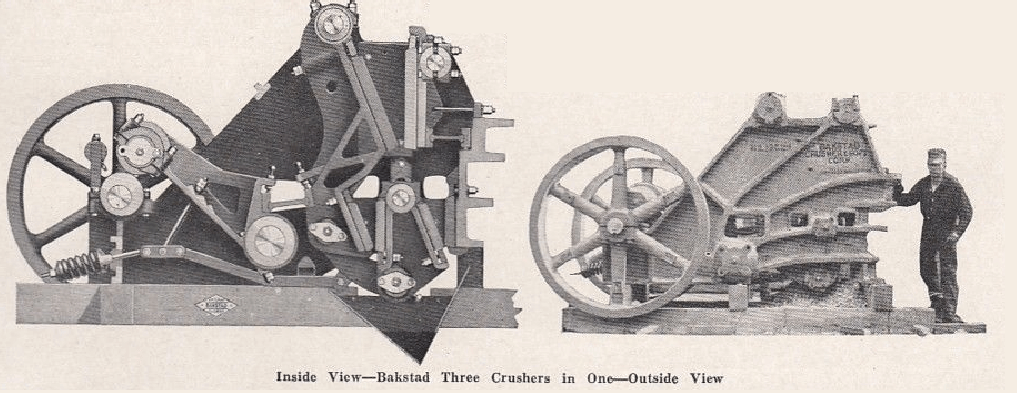

How Bakstad Combines Three Crushers in One: You will readily note the three separate crushing paths, the upper one for primary and the lower two for secondary reduction. The primary jaw reduces the large rock to a size suitable for the two secondary crushing units. These open and close in unison with the primary jaw. Only two principal moving parts have been added to convert an ordinary jaw crusher into the Bakstad 3-Jaw Crusher. There is nothing complicated about this three-jaws-in-one crusher—nothing to get out of order—no new principles are involved—the proven principles of the jaw crushers have not been deviated from.

Adjustable for Fine or Coarse Products: The adjustment necessary to obtain the desired product is an extremely simple operation which requires but a minimum of time. It is only necessary to change the main adjustment toggle to the proper size. This adjustment affects all three jaws proportionately, but always leaves the secondary opening equally spaced. The stationary jaw of the primary crusher is also adjustable by changing its toggle. Thus the relation between the primary and secondary paths can always be equalized for the different adjustments. and the variations in the friability of materials to be crushed. These adjusting toggles are slipped in through the port holes in the frame and are held in place by a lug on the seat which fits into a corresponding pocket in the toggle. It cannot work out while the crusher is in operation. The adjustment does not require more than a few minutes. The settings range from 2.5″ inch material to 0.5″ in the stock size models.

Description: The main Frame and all other principal parts; are of open-hearth cast steel, accurately machined and fitted. All bearings are dust proof and provided with high pressure lubricators throughout, reversible for wear, quickly removable and made of the beet metals obtainable for their individual, particular duties. The Crushing Plates are of man-ganese 6teel, reversible for wear and interchangeable from stationary to moving jaw in both the primary and secondary paths. Adjusting Toggles, wedge bolts, etc., are readily accessible and the secondary jaw openings arc reached through suitable portholes in the side frame.

Bakstad Portable for Contractors: Crushers are also furnished mounted on 4-wheel, steel beam trucks with 5th wheel construction for operation as portable units. These may be operated in conjunction with standard portable conveyors, bins, etc., or furnished complete with continuous steel bucket, collapsible and folding elevators, by-pass grizzly or vibrating screens. Elevators with folding features are furnished in lengths up to 25 ft.

Rigid elevators in any length required. An important feature of these Portable Crusher Models is the fact that the secondary jaws may be set to produce the product desired without screening.

The Original Crusher Patent