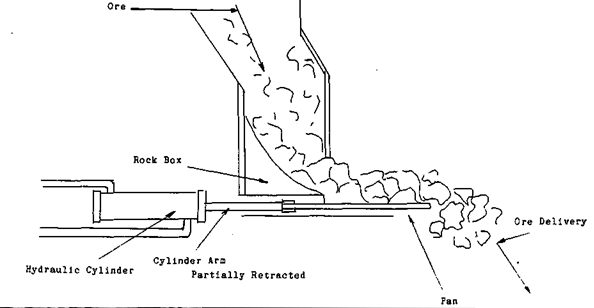

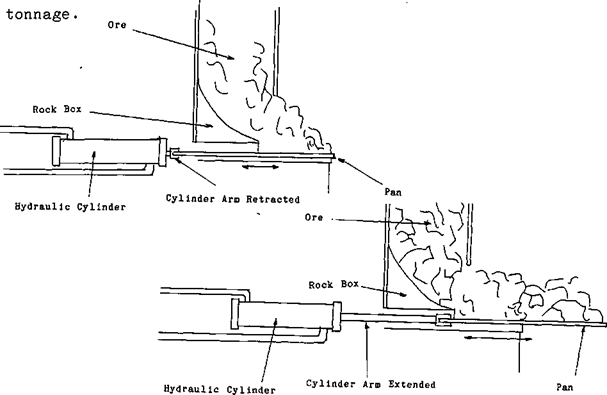

The next feeder on the list is the PAN FEEDER, this one may also be called the reciprocating feeder and it works like this. The pan moves back under the ore picking up a load, it then slides forward carrying the ore with it. The pan is pushed forward then retracted. As the pan is withdrawn the ore is forced off by the weight of the ore behind the original load.

The tonnage is controlled by the speed that the pan completes a cycle, the faster the pan moves the higher the tonnage.

An area of concern for the operator is that it doesn’t handle wet ore well as it tends to wash the load off of the pan. This will create a lot of spillage which will have to be cleaned up. If the ore is too wet it can also be very hard to control the tonnage. Neither one of these problems will make operators very happy.