The chief oxidising agents (which are also de-sulphurisers) are the following:

Nitre, or Potassic Nitrate.—This salt fuses very easily to a watery liquid. It oxidises most combustible substances with deflagration, and thereby converts sulphides into sulphates, arsenides into arsenates, and most metals into oxides. In the presence of strong bases, such as soda, the whole of the sulphur is fully oxidised; but in many cases some arsenic is apt to escape, and to give rise to a peculiar garlic-like odour. The sulphates of soda and potash are thus formed, and float as a watery liquid on the surface of the slag.

Red lead is an oxide of lead. About one-quarter of its oxygen is very loosely held, and, hence, is available for oxidising purposes, without any separation of metallic lead. The rest of the oxygen is also available; but for each part of oxygen given off, about 13 parts of metallic lead are deposited. In silver assays this power of readily giving up oxygen is made use of. The residual oxide (litharge) acts as a flux.

Hot air is the oxidising agent in roasting operations. The sulphur and arsenic of such minerals as mispickel and pyrites are oxidised by the hot air and pass off as sulphur dioxide and “ white arsenic.” The metals generally remain in the form of oxide, mixed with more or less sulphate and arsenate. The residue may remain as a powdery substance (a calx), in which case the process of roasting is termed calcination; or it may be a pasty mass or liquid. In the calcination of somewhat fusible minerals, the roasting should be lone at a low temperature to avoid clotting; arsenic and sulphur being with difficulty burnt off from the clotted mineral. A low temperature, however, favours the formation of sulphates; and these (if not removed) would reappear in a subsequent reduction as sulphides. These sulphates may be decomposed by a higher temperature towards the end of the operation ; their removal is rendered more certain by rubbing up the calx with some culm and re-roasting, or by strongly heating the calx after the addition of solid ammonic carbonate. In roasting operations, as large a surface of the substance as possible should be exposed to the air. If done in a crucible, the crucible should be of the Cornish type, short and open, not long and narrow. For calcinations, roasting dishes are useful: these are broad and shallow, not unlike saucers, but unglazed. In those cases in which the products of the roasting are liquid at the temperature used, a scorifier (fig. 38) is suitable if it is desired to keep the liquid ; but if the liquid is best drained off as quickly as it is formed, a cupel (fig. 5) should be used.

A scorifier is essentially a roasting dish sufficiently thick to resist, for a time, the corrosive action of the fused metallic oxides it is to contain. The essential property of a cupel is, that it is sufficiently porous to allow the fused oxide to drain into it as fast as it is formed. It should be large enough to absorb the whole of the liquid; and of course must be made of a material upon which the liquid has no corrosive action. Cupels do not bear transport well; hence the assayer generally has to make them, or to supervise their making. A quantity of bone ash is carefully mixed with water so that no lumps are formed, and the mixture is then worked up by rubbing between the hands. The bone ash is sufficiently wet when its cohesion is such that it can be pressed into a lump, and yet be easily crumbled into powder. Cupel moulds should be purchased. They are generally made of turned iron or brass. They consist of three parts (1) a hollow cylinder; (2) a disc of metal; and (3) a piston for compressing the bone ash and shaping the top of the cupel. The disc forms a false bottom for the cylinder. This is put in its place, and the cylinder filled (or nearly so) with the moistened bone ash. The bone ash is then pressed into shape with the piston, and the cupel finished with the help of three or four smart blows from a mallet. Before removing the piston, turn it half-way round upon its axis so as to loosen and smooth the face of the cupel.The cupel is got out by pressing up the disc of metal forming the false bottom ; the removal is more easily effected if the mould is somewhat conical, instead of cylindrical, in form.

The cupels are put in a warm place to dry for two or three days. A conveniently sized cupel is inches in

diameter and about ¾ inch high. The cavity of the cupel is about ¼ inch deep, and something of the shape shown in fig. 5.

There are two kinds of furnaces required, the “wind” and “ muffle ” furnaces. These are built of brick, fire-brick, of course, being used for the lining. They are connected with a chimney that will provide a good draught. Figure 6 shows a section of the wind furnace, fig. 7 a section of the muffle furnace, and fig. 8 a general view of a group comprising a muffle and two wind furnaces suitable for general work. When in operation, the furnaces are covered with iron-bound tiles. The opening under the door of the muffle is closed with a loosely fitting brick. The floor of the muffle is protected with a layer of bone-ash, which absorbs any oxide of lead that may be accidentally spilt. The fire bars should be easily removable.

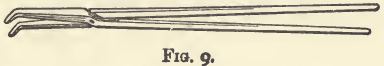

Few tools are wanted; the most important are some cast-iron

moulds, tongs (fig. 9), stirrers for calcining (fig. 10), and light tongs of a special form for handling scorifiers and cupels (see Silver).

![]()

The coke used should be of good quality; the formation of a fused ash (clinker), in any quantity, causes ceaseless trouble, and requires frequent removal. The coke should be broken into lumps of a uniform size (about 2 in. across) before being brought into the office. The furnace should be well packed by stirring, raising the coke and not ramming it, and it should be uniformly heated, not hot below and cold above. In lighting a furnace, a start is made with wood and charcoal, this readily ignites and sets fire to the coke, which of itself does not kindle easily.

In commencing work, add (if necessary) fresh coke, and mix well; make hollows, and into these put old crucibles; pack around with coke, so that the surface shall be concave, sloping upwards from the mouths of the crucibles to the sides of the furnace; close the furnace, and, when uniformly heated, substitute for the empty crucibles those which contain the assays. It is rarely advisable to have a very hot fire at first, because with a gradual heat the gases and steam quietly escape through the unfused mass, while with too strong a heat these might make some of the matter in the crucible overflow. Moreover, if the heat should be too strong at first, the flux might melt and run to the bottom of the crucible, leaving the quartz, &c., as a pasty mass above; with a gentler heat combination is completed, and the subsequent fiercer heat simply melts the fusible compound into homogeneous slag.

The fused material may be left in the crucible and separated from it by breaking when cold. It is generally more convenient to pour it into cast-iron moulds. These moulds should be dry and smooth. They act best when warmed and oiled or black-leaded.

Air entering through the fire-bars of a furnace and coming in contact with hot coke combines with it, forming a very hot mixture of carbonic acid and nitrogen; this ascending, comes in contact with more coke, and the carbonic acid is reduced to carbonic oxide ; at the top of the furnace, or in the flue, the carbonic oxide meeting fresh air, combines with the oxygen therein and re-forms carbonic acid. In the first and third of these reactions, much heat is evolved ; in the second, the furnace is cooled a little. It must always be remembered, that the carbonic oxide of the furnace gases is a reducing agent. When these gases are likely to exert a prejudicial effect, and a strongly oxidising atmosphere is required, the work is best done in a muffle.