Table of Contents

The problem of treating oxidized lead ores and many other oxides is complex due to the nature of the ore and to the soft, sliming characteristics of the lead oxides. These ores are usually of a sticky nature, being high in primary slimes, and are difficult to handle and feed. The lead carbonate as cerussite is very soft and tends to slime readily in crushing and grinding circuits. Soluble sulphates, particularly iron salts together with aluminum compounds, are detrimental to subsequent treatment by flotation, leaching and filtering. It is therefore necessary to recover the lead minerals at coarse sizes, as soon as free, by gravity means to affect maximum recovery. The lead sulphate as anglesite responds readily to flotation when sulphidized and can be recovered at finer sizes.

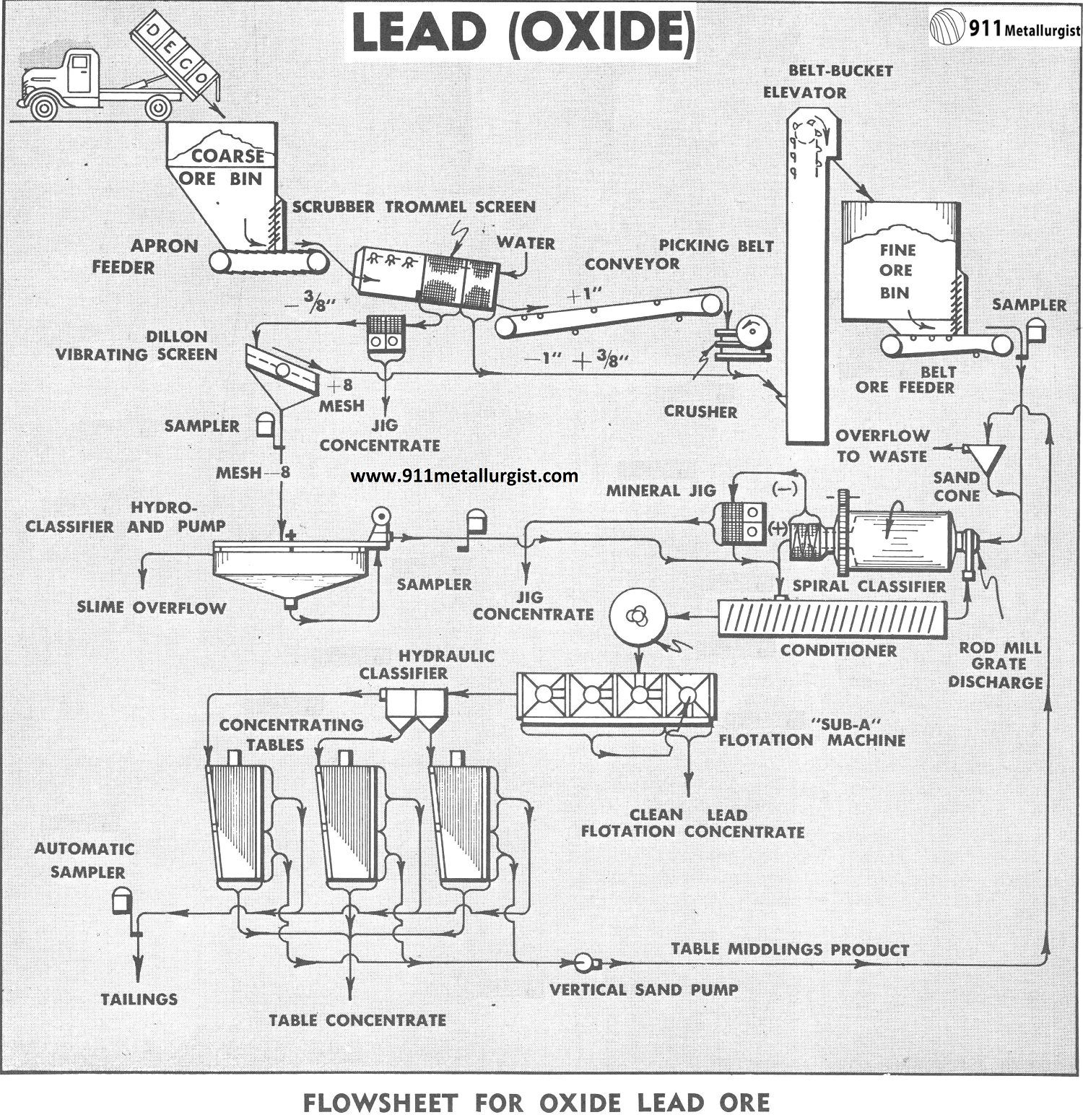

Lead Oxide Gravity Flotation Process Flowsheet

The flowsheet is designed to provide for continuous operation of the washing and crushing sections. This is done to eliminate some of the troublesome factors involved in the handling, crushing and storage of sticky ores of this type. Extensive washing and disintegration is used to free the mineral from the primary slimes ahead of screening. The real merit of this flowsheet is to separate the primary slimes from the ore and then to remove any freed coarse mineral by jigs or tables and avoid further sliming by using the proper type of grinding mill with the quick removal of the fines before and after each stage. Jigging is used on all -3/8″ material of the original washed ore, recovering a large percentage of both the fine and coarse freed mineral. The washed oversize feed is hand picked to remove either waste material or high grade ore prior to crushing. Note the sampling arrangements provided for accurate sampling are required for mill control. Special attention is called to the jig in the rod mill classifier circuit, and to the return and treatment of the middling products to produce the highest recovery and grade.

Washing and Crushing Lead Oxide Ore

Oxidized ores give trouble from the time the ore enters the mill ore bin until the tailings reach the tailings pond. The ore is removed from the primary bin by means of an oversize apron feeder of the heavy duty type. Louvers should be available on the front or sides of the ore bin to enable the operator to poke the ore down into the apron feeder and thus prevent bridging. The feeder is positive and can plow through a sticky, gummy ore to give a constant, even feed to the washing scrubber trommel screen. The trommel has a washing section to disintegrate and pulp all fine materials by means of baffles, lifter bars and spray water. This is no easy task for this disintegration is essential and requires a heavy duty trommel mechanism. The washed material is screened to —3/8″ in the first screening section and to — 1″ in the second screen section of the trommel. The plus 1″ material is discharged to a picking belt which in turn feeds a Jaw Crusher, set at 1″ opening. Any free mineral or even clean gangue removed from the picking belt is a low cost factor and thus the importance of the thorough washing of the ore. The —3/8″ fraction goes by gravity to a Mineral Jig which produces a final jig concentrate from the slimy — 3/8″ mill product. This jig, due to its selective action saves the fine mineral as well as the coarse sizes. Very coarse lead minerals, if present, can be discharged by means of a center draw- off attachment on the jig.

The mineral jig tailings discharge over a Vibrating Screen and are wet screened to give a minus 6 or 8 mesh product. This is a critical point in the circuit and ample screen surface with efficient vibration is needed. The plus 6 or 8 mesh material from the vibrating screen joins the plus 3/8, minus 1″ from the trommel together with the minus 1″ product from the jaw crusher and is conveyed and then elevated to a small storage or surge bin. This small surge bin with its feeder is provided only to give a constant feed to the grinding section and is not intended for the storage of any large amount of ore. The minus 6 or 8 mesh from the vibrating screen is put through a Hydroclassifier for the removal of the colloidal slimes. The deslimed sand product from the hydroclassifier is pumped to the Spiral Classifier in the rod mill circuit. In some cases the slime overflow from the hydroclassifier may go to rag tables to recover contained values. Even though on some ores these primary slimes may be floated in a separate circuit or shipped direct, we must, in most cases, be careful not to allow these primary slimes to enter the main mill circuit.

Grinding Pb Oxide Ore

The crushed ore and the screened products discharged by the bucket elevator are fed from the small surge bin to insure a uniform feed to the grinding circuit by means of a Adjustable Stroke Ore Feeder. The rod mill is provided with grate discharge liners and Spiral Screen with ¼” openings. The grate discharge rod mill reduces overgrinding and sliming of the lead minerals. The rod mill discharge passes over a Mineral Jig and to a Spiral Classifier. Most oxides and carbonates are easily broken down in any type of grinding unit and care should thus be given to the removal of the freed mineral as quickly as possible. The mineral jig, due to its selective action and low water consumption, produces a high grade concentrate.

Pb Oxide Recovery by Flotation and Tabling (Shaker Table)

The Spiral Classifier overflows a product of about 65 mesh directly to a Conditioner where Sulphidizer, sodium bicarbonate and a frother are added. This reagent combination produces nascent hydrogen sulphide, which is most active when initially produced. The sulphidized minerals are then subjected to quick flotation in a “Sub-A” Flotation Machine where a cleaned mineral concentrate is made. Naturally the coarser the mineral is floated the better, and here the “Sub-A” with its distinct gravity flow principle is most efficient and essential. The flotation concentrate is dewatered in a Thickener and filtered by a Disc Filter. The flotation tailings are classified to give sized products, which are then tabled to give a final tailing, a middling product and a table concentrate. The table middlings are pumped to a dewatering sand cone prior to regrinding in the rod mill to effect further recovery of the lead values from the middling product.

Summary the Pb Oxide Beneficiation Process

This flowsheet provides for the thorough washing and disintegration of the ore for the recovery of the lead minerals at a coarse size by gravity, and for the removal of colloidal primary slimes ahead of further treatment by flotation and gravity means. The grinding circuit is designed to avoid the sliming of the mineral which is so essential in the concentration of lead oxide ores. The age old principal of “removing the mineral as soon as freed” is surely applicable on these oxide ores.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.