Table of Contents

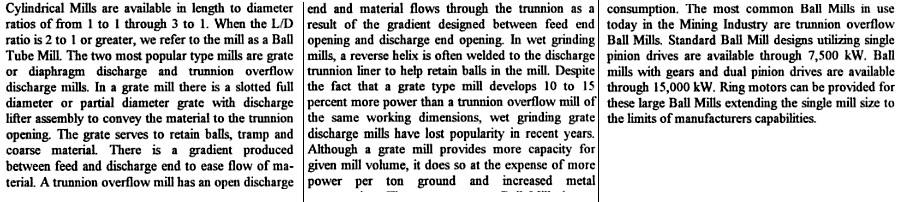

Allow me to compare: Ball mills can be of the overflow or of the grate discharge type. Overflow discharge mills are used when a product with high specific surface is wanted, without any respect to the particle size distribution curve. Overflow discharge mills give a final product in an open circuit.

Grate discharge mills are used when the grinding energy shall be concentrated to the coarse particles without production of slimes. In order to get a steep particle size distribution curve, the mill is used in closed circuit with some kind of classifier and the coarse particles-known as classifier underflow-are recycled.

Furthermore, it should be observed that a grate discharge ball mill converts about 20% more energy than an overflow discharge mill with the same shell dimensions.

In the past, I had worked with +10% as an expected increase created by the conversion. How much capacity you gain by using grate discharge over overflow discharge on a mill = The +20% data comes from an old paper.

If you do not need a deep primary grind, a retrofit/conversion might be of value. A very high impact opportunity to increase your ball mill tonnage.

The cost of a ball mill conversion from overflow to grate discharge is ‘fairly’ affordable at $65,000 for a 13′ x 15′ mill. This is only for the discharge head, grates and pulp filters (rubber).

A comparison in laboratory of Overflow Discharge Ball Mill VS Grate Discharge Ball Mill.

Types of Ball Mills

Grinding mills can by classified by which types of discharge the ball mill has installed to let out the ground slurry. Best is rapid change of mill content results in higher efficiency.

Ball Mills have a very large discharge opening or area and smaller area for incoming feed. The gradient between the incoming feed opening and the discharge near the periphery of the shell provides a faster migration of the fines than the oversize particles. In deep pulp level mills commonly known as “overflow mills” this migration can not occur since material enters and leaves at the same level by displacement only. Independent tests have shown that regardless of mill shape or design, the discharge product of an overflow mill will be the same no matter at which end the feed enters.

Grate Discharge Ball mills with low pulp levels benefit from the full impact of the grinding media acting on the ore particles, as it falls into the shallow pulp. With a deep pulp level the grinding media is cushioned in the pulp, thus losing its energy and reducing its grinding ability. Grate Discharge Ball Mills have shown 25% to 45% more tonnage ground and a substantial reduction in power consumed per ton of material compared size for size with overflow mills.

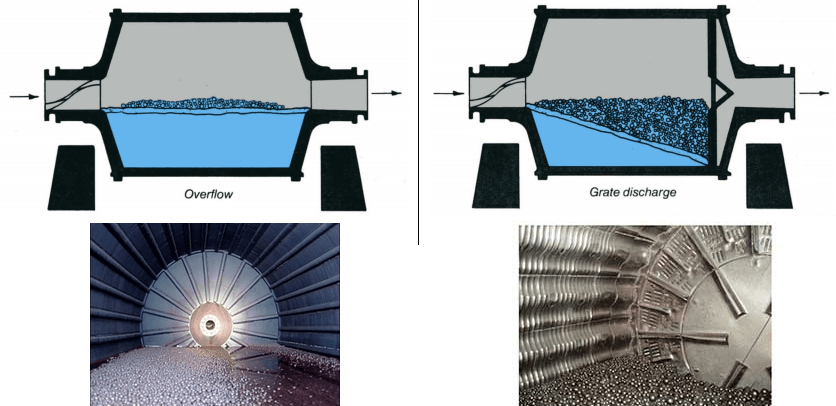

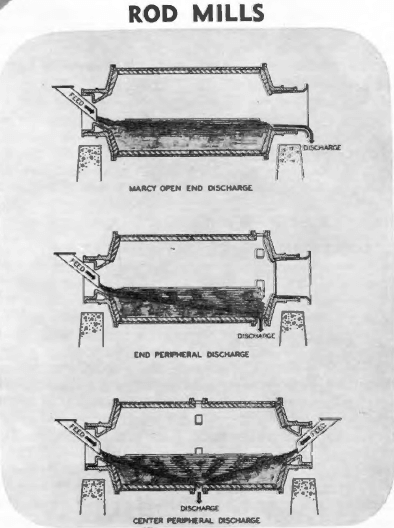

To illustrate the characteristics of various type mills we have shown the types of discharge for rod mills and ball mills. There are essentially four types of rod mill discharge:

- the overflow type

- the End Grate Discharge

- the end peripheral discharge

- the center peripheral discharge

In the case of ball mills these are the overflow type, semi-grate or intermediate pulp level discharge, and the true grate discharge.

A general statement can be made that the closer the discharge is to the periphery of the shell, the quicker the material will pass through and less overgrinding will take place. This is important in both rod mill and ball mill grinding. First, regardless of how fine a grind is required, overgrinding is costly and undesirable. The ideal condition is to remove the particles as soon as they have reached the optimum size. Secondly, in grinding applications where a minimum amount of fine material is preferred, again a rapid flow through the grinding mill is required. These can be accomplished with the grate for ball mill operations, or the various Grate Discharge discharge arrangements for the rod mill.

The discharge end of the conventional Open End Rod Mill is virtually open as the name implies.

As a means of controlling splash and to prevent unruly rods from moving out of the mill a discharge plug or plug door arrangement is furnished. The use of this construction permits pulp to discharge freely around the annular opening between the plug and the discharge trunnion liner. By simple removal of the plug the full large area of the discharge end may be used for re-rodding, inspection of the mill when in operation, and an easy access to the mill interior for relining. This large opening does away with the necessity of manholes for mill entrance as commonly employed in the overflow type mill. The plug door arrangement is a great time saver during re-rodding and re-lining operations.

On smaller diameter Grate Discharge Rod Mills a discharge plug is furnished mounted on the trunnion liner and extending through to line up with the discharge head liners. The larger diameter Grate Discharge Mills are furnished with a discharge housing arrangement independent of the mill. A hinged door is mounted in this housing and easily swings in or out of the discharge trunnion liner. These housings are also used to control the direction of discharge pulp flow leaving the mill. Such flow may be directed to the left, right, or directly below the mill centerline.

The discharge housing is of very heavy construction for strength and rigidly. Maintenance of this housing is kept at a minimum, the only wearing part being the replaceable Manganese Steel plug door liner.

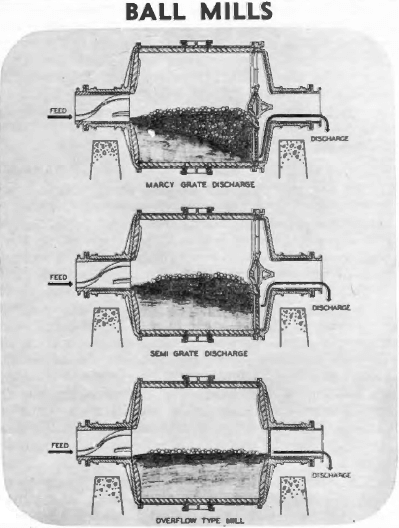

The discharge end of a Grate Discharge Ball Mill is fitted with grate sections approximately 3½” thick, made of special heat treated alloy steel developed for this particular application. The grate sections have tapered openings between ¼” and 7/8″ dependent upon the specific grinding application. These are selected to provide the greatest efficiency for any particular job. The grate sections are held in place by tapered Manganese Steel side clamp bars, a center discharge liner, and end clamp bars. The discharge grates are very simple to install and require no attention during operation. The overall life of the discharge end parts generally is greater than that of the feed head liners or shell liners. The discharge end of the Grate Discharge Ball Mill has at least ten times the discharge opening area, through the grate slots, compared to the common trunnion overflow type mill. The discharge grates are designed to run clean and free of any blinding or choking. The pulp level in the mill may be varied by merely changing the pulp dilution. There is no complicated mechanical arrangement to compensate for pulp level changes. The side clamp bars and center discharge liner besides holding the grate sections in place, act as a means of stirring up the ball charge and reduces the amount of wear on the grate sections. The pulp discharges through the grate slots into a lifter compartment in the discharge head, lined with replaceable wearing parts. This lifting compartment elevates the discharge pulp up to the level of the discharge trunnion liner opening and spills this against a deflecting cone which directs it out through the trunnion liner.

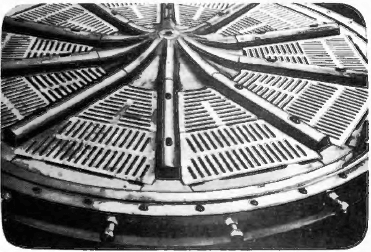

The above is a Grate Discharge Mill head with discharge grates, side clamp bars, end damp bars, and center discharge liners in place. The grates and side clamp bars are accurately ground to fit the machined surfaces of the discharge head lifters.

Ball Mill Grinding

We have already discussed grinding in a general way and have referred numerous times to the grate discharge principle of grinding. To illustrate roughly this principle, take a certain weight of crushed ore and grind it with a mortar and pestle until all of the ore particles will pass through a 65-mesh screen. Then take a similar sample but this time grind for a few minutes and screen at 65-mesh removing the finished material, then return the oversize particles and grind for another short period of time and repeat the screening operation. You would find that the actual net grinding time required for the second sample is about half the time required under the first condition. This same process takes place in the Grate Discharge Ball Mill. It must be borne in mind that it is the classifier which determines the size of the finished product, not the grinding mill itself. The Grate Discharge Mill permits a quick discharge of the finished material into the classifier which makes the desired mesh size separation and returns the oversize particles to the mill for another pass. Contrary to the usual belief, material does not discharge through the grates at the bottom. In fact it is carried up in the ball load so that the greater portion passes out from the ball load on the upturning side of the mill, in the grate area from about half way below the centerline of the mill, on up to the point where the balls start to leave the shell on their downward paths. This indicates then that the thick pulp carried in the mill is well within the ball mass where the actual grinding is taking place. The discharge grates are not to control the size of particle discharged, but merely to retain the grinding balls within the mill, provide the full discharge area required, and form the steep gradient between the feed entrance and product discharge.

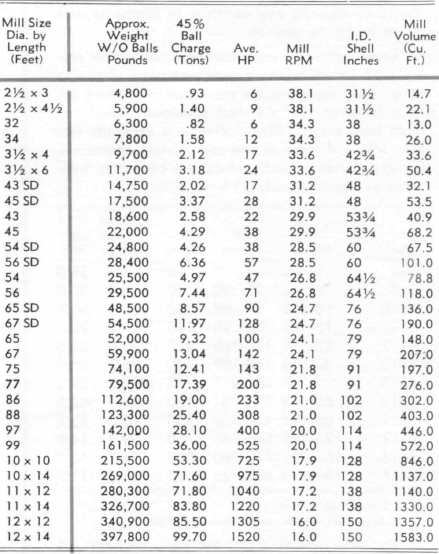

Example of Plant Capacity Gains

To illustrate the comparison of the grate discharge Ball Mill to an overflow type of mill we are showing on page 31 several actual case histories of installations where the performance of grate discharge mills versus overflow mills have been proven. In each such test, run for long periods of time, the ore characteristics and size of feed were maintained identical so that the tests could be compared under like conditions. It will be noted that in each case the grate discharge Mill provided a high increase in tonnage with a lesser increase in power consumption so that the actual KWH per ton consumed was reduced. From these field examples you can verify the previous statement that an overflow type of mill has somewhere near 70% the capacity of the grate mill. These tests were conducted independently by the actual operating companies involved.

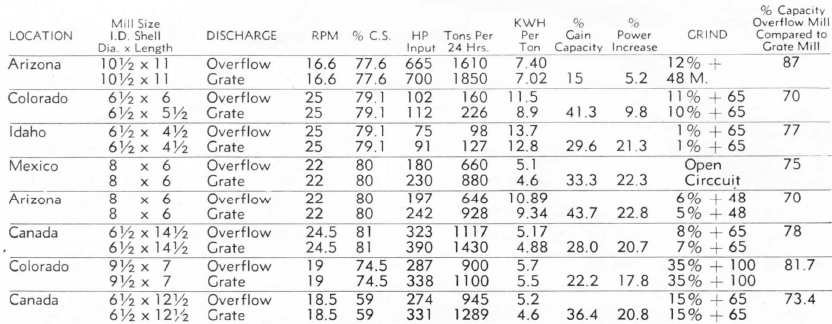

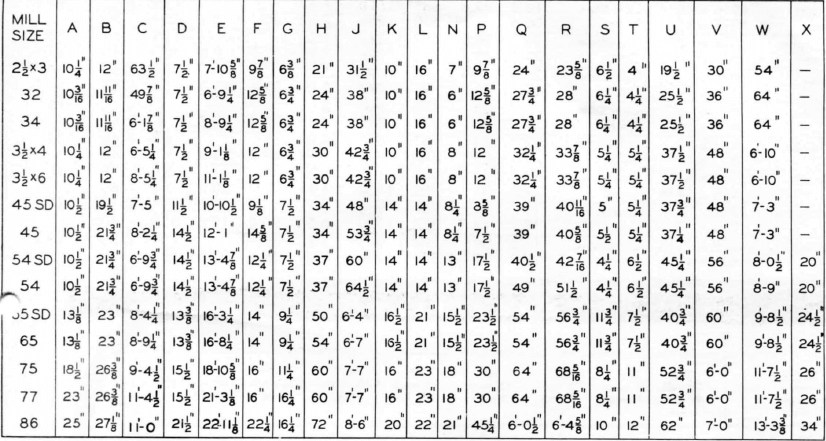

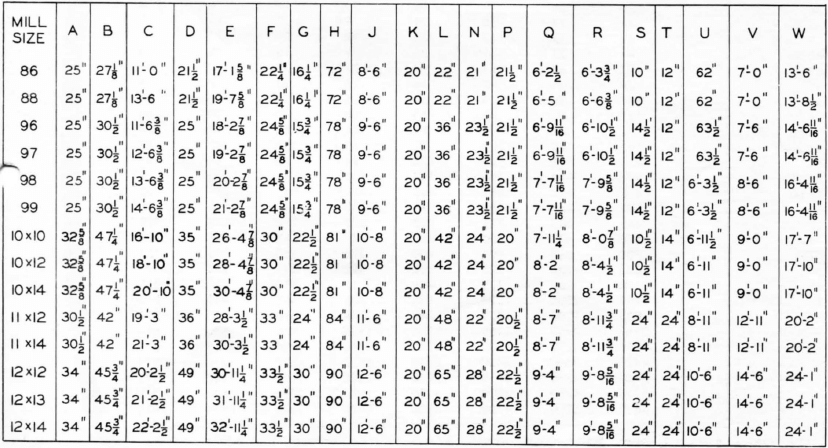

Ball Mill Specifications

Compare Type of Mill Discharge

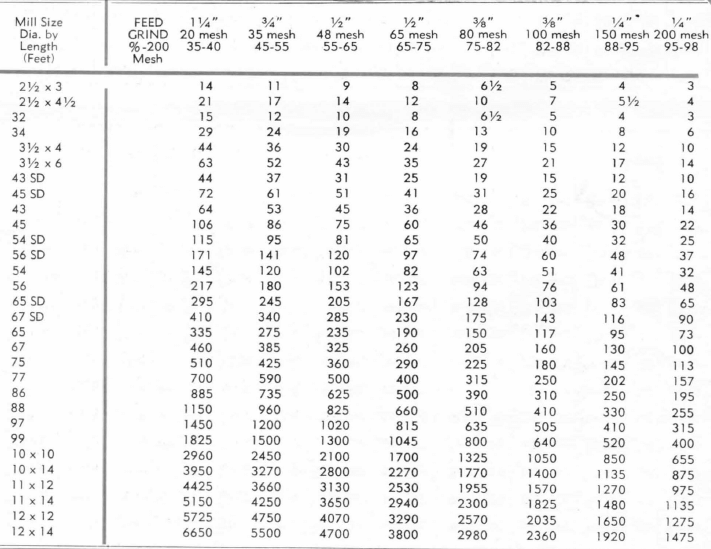

Grate Discharge Ball Mill Capacities

The above tables list some of the most common Grate Discharge Ball Mill sizes. Capacities are based on medium hard ore with mill operating in closed circuit under wet grinding conditions at speeds indicated. For dry grinding, speeds are reduced and capacities drop between 30% to 50% .

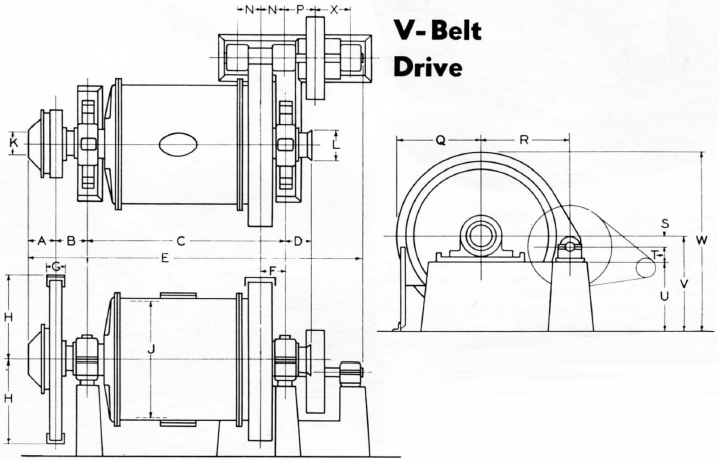

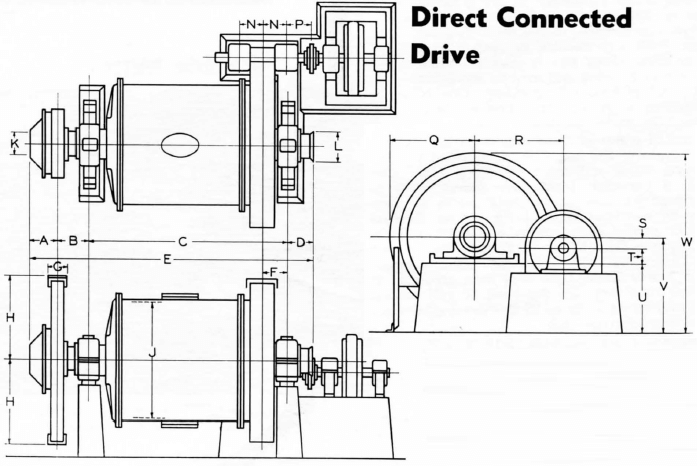

Grate Discharge Ball Mill Arrangement & Dimensions

The above dimensions are approximate and for preliminary use only. Right hand mills are shown. For left hand mills put drive on opposite side. Drive may also be located at feed end. but clearance of scoop must be considered.

The above dimensions are approximate and for preliminary use only. Right hand mills are shown. For left hand mills put drive on opposite side. Drive may also be located at feed end, but clearance of scoop must be considered.

https://www.911metallurgist.com/how-a-grate-discharge-ball-mill-work