These depressants are organic mixtures reacted with inorganic salts. They have found application for depression of oxidized pyrite, marcasite and pyrrhotite during the flotation of Cu, Cu-Zn, Cu-Pb-Zn and Pb-Zn ores. Some of these depressants have been adapted for depression of zinc during sequential copper zinc flotation. Depressants from the DS series have been successfully applied at Nanisivik Concentrator and Tara Mines (Ireland). The effectiveness of DS22 depressant for pyrite rejection during lead flotation, compared with cyanide, is illustrated in Fig. 9.

In the presence of the organic depressant, pyrite flotation was effectively retarded with no deterioration in the recovery of lead. Organic depressants from the LS series are effective for both pyrite and zinc depression during sequential Cu, Cu-Pb and Pb-Zn flotation. These depressants may be used in a wide pH range and are usually added with conventional depressants (lime, SO2 etc).

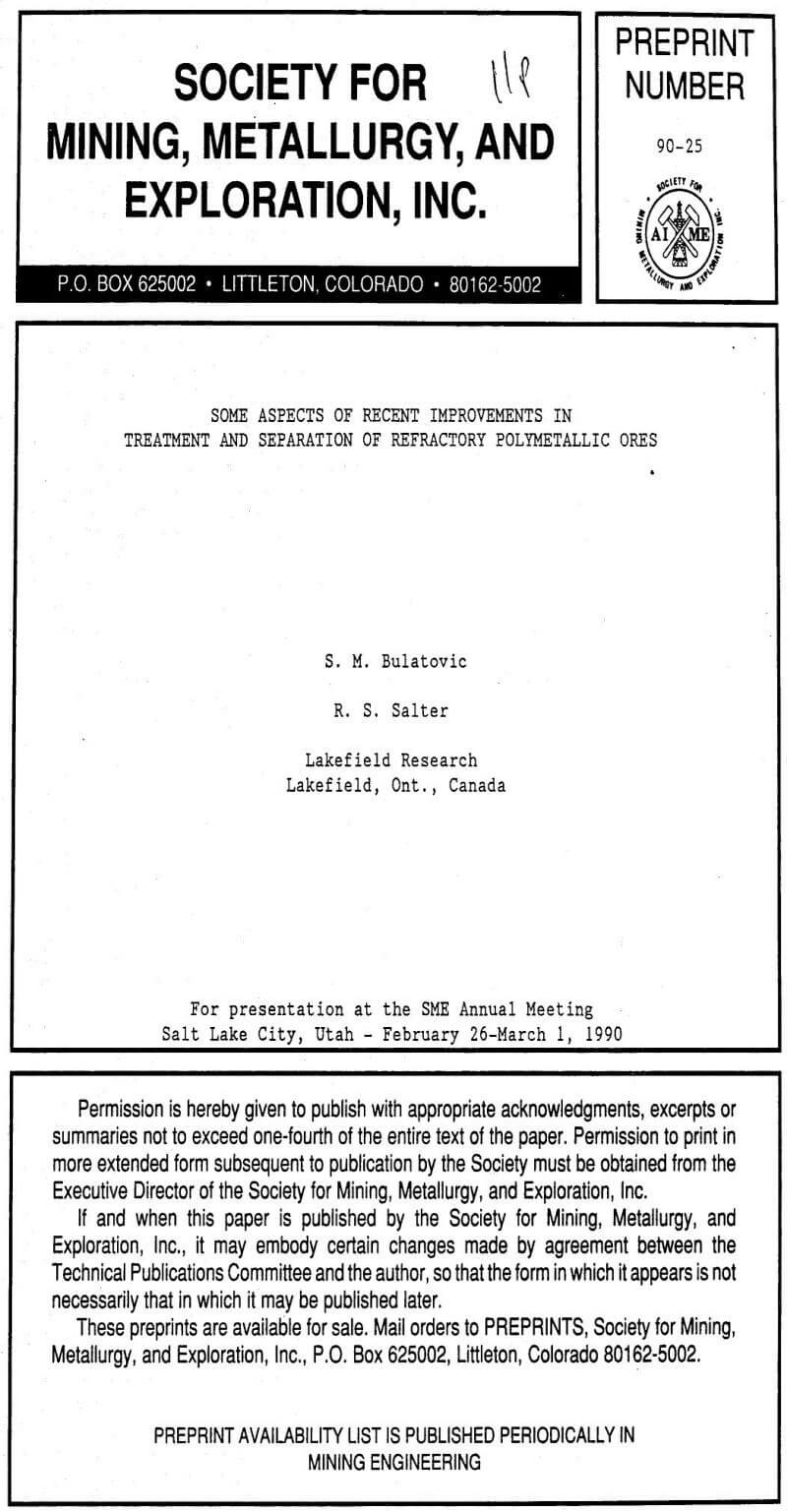

Table 5 compares the metallurgical results obtained with LS8 depressant and the conventional lime-NaCN-SO2 depressants during the flotation of a copper-zinc ore.

Excellent zinc rejection from the copper concentrate was obtained with depressant LS8 without reduction in copper recovery.

One seriously neglected area in mineral processing plants has been the pulp pretreatment step, which in most cases was not even considered as a part of the flowsheet. Traditionally, in the laboratory development testwork, a laboratory cell is used as the conditioner. Conditioning times were recorded but power input per unit of pulp is rarely measured. Thus, the motor selection for the conditioners was left to engineering and mixing companies. Such practices led to the design of commercial conditioners which were under-powered and in most cases were by-passed after plant start-up because of sanding problems. Frequently, in order to save space, conditioners were omitted from the flowsheet.

The pulp pretreatment step (i.e. conditioning) during the treatment of massive sulphide ores is highly important and. must be considered an integral part of the flowsheet. Some of the problems associated with the transfer of new technology into commercial plants, in particular reagents, is attributed to the non-optimum flowsheet configuration or the lack of conditioning facilities in the actual plant. Extensive laboratory testwork in this area has been carried out to establish the effect of conventional conditioning and to evaluate the effectiveness of high intensity conditioning on flotation of mineral slimes. Appreciable progress has been made in the application of high intensity conditioning for flotation of mineral fines.

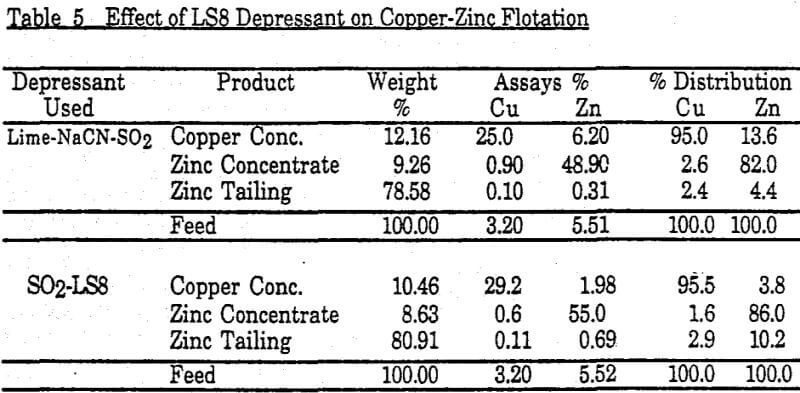

Conventional Conditioning: Many factors influence the requirements for pulp conditioning during the treatment of massive sulphide ores. Some of the decisive factors include the following: rapid oxidation of minerals during flotation, ( resulting in an increased concentration of ions in the pulp); the use of insoluble collectors or depressants that are time dependent for reaction; and, in sequential flotation, when the valuable mineral is depressed, reactivation for subsequent flotation is time dependent. Conditioning time can be important in many instances, but the power input per unit of pulp volume determines the effectiveness of the conditioning. Fig. 13 shows the effect of power input on zinc concentrate grade and recovery using a constant conditioning time of 15 minutes (i.e. 10 minutes with CuSO4 plus 5 minutes with collector). These data were obtained from a copper-zinc ore in which lime-SO2 was used as the zinc depressant during copper flotation.

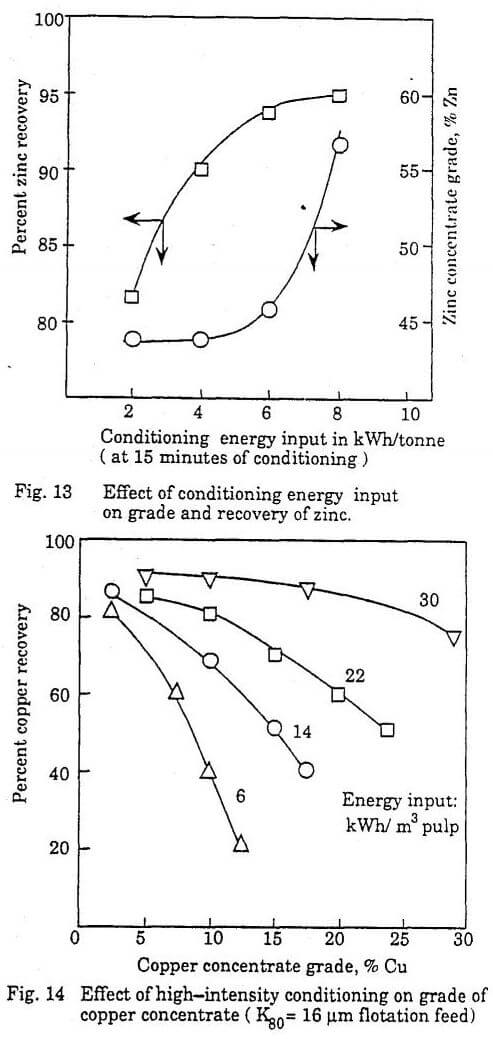

High-Intensity Conditioning has been examined on many polymetallic ores as a means of improving flotation of valuable minerals from ultrafine slimes. High-intensity conditioning in the presence of a collector, frother and a suitable modifier, can significantly improve the recoveries and the selectivities of ultrafine sulphide mineral slimes. A typical grade-recovery curve from a finely disseminated massive sulphide copper ore ground to 16 µm, with different power inputs in the conditioning stages applied to flotation and cleaner feed, are illustrated in Fig. 14.

Without high-intensity conditioning it was impossible to achieve a marketable concentrate grade from this ore. It has been postulated that most of the improvement with high-intensity conditioning comes from the selective collector adsorption and the creation of fine particle aggregates which are readily floatable. Without the addition of collector to the high-intensity conditioner, the results are either equal to or below those obtainable by conventional conditioning.