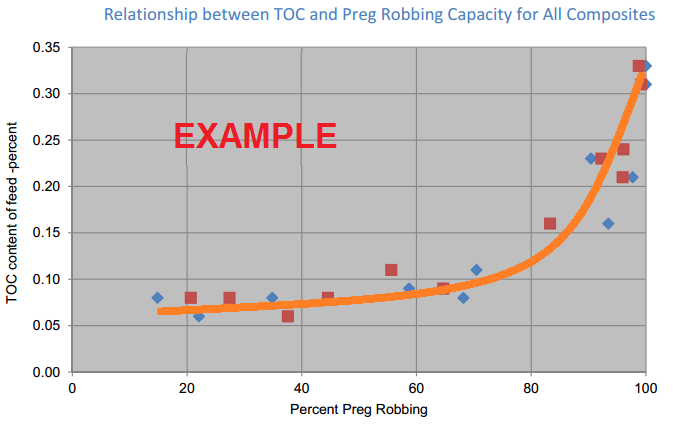

Organic carbon is a common problem for base metal production and precious metal leaching. In froth flotation, liberated organic carbon is naturally hydrophobic and will be recovered with the other minerals, lowering the grade of the concentrates. It can also adsorb collectors and frothers, reducing the efficiency of the mineral recovery process. In leaching, the absorption properties can remove precious metals from solution before the metals are extracted by the intended process adsorption routes.

To determine if the organic carbon would cause problems with gold adsorption or “preg robbing”, gold spike tests were performed. The preg‐robbing tests were conducted with three levels of gold solution, 0 mg/litre or blank, 3mg/litre. Some samples were subjected to even higher spike values of 12mg/litre. To calculate the percent adsorption of gold (percent preg‐robbing) the following calculation is used:

Laser Raman spectroscopy can be used to estimate the preg‐robbing capability of the carbonaceous material. There are cases where the analysis can indicate that the carbonaceous material in the flotation feed is a close match to activated carbon and therefore would exhibit strong preg‐robbing characteristics. How “active” the natural carbon is will dictate its preg-robbing capability and its impact on gold recovery.

An alternative method involving iodine adsorption is often evaluated and compared to preg-robbing test results for the method employed with leach solutions with and without a gold spike. Results from the iodine adsorption method may not correlate well to the pregrobbing tests for Sulphide composites. When this happens its use as a substitute for the preg-robbing test is not recommended.

Control & Removal of Organic Carbon

The effects of carbon can be mitigated in froth flotation by using the natural hydrophobic properties to remove in advance of other mineral recovery, often referred to as a pre-flotation process. Or the carbon can be depressed with the use of starches. Often both techniques are required to manage organic carbon in the flotation process.

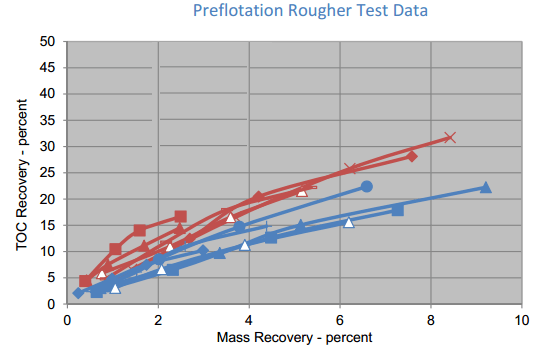

To assess the nature of the organic carbon in the samples, a kinetic rate pre‐flotation test are conducted. The tests are conducted at natural pH, with only frother. Below is an example of multiple TOC pre-float tests.

Sometimes, fuel oil (FO) is used as a possible collector for TOC.

TOC Organic Carbon Depressant: Carboxymethyl cellulose (CMC), a common depressant best tested at various dosage levels and as high as 500 g/tonne. Other depressants to try; a mixture of CMC and guar gum (PE26) and Quebracho (F100).

For most of the batch cleaner test work, a rougher pre‐flotation concentrate is produced. The mass of the concentrate can range from 1 percent to 20 percent of feed mass depending on the ore. To reduce metal losses to the pre‐flotation circuit, a series of dilution cleaner stages must performed. Typically TOC is upgraded by cleaning. Beware that in some cases TOC losses can be relatively high in the cleaner tailings. The objective is to only be rejecting metal to the pre‐flotation tailings.

Removal of any free TOC with preflotation should be theoretically beneficial to the downstream flotation and leach processes.