For design purposes, you need an estimation or prediction of your SAG Mill’s tonnage; well, there are 3 ways to generate good rock “ore” hardness testing data for SAG and ball mill circuit grindability from half drill core. We can abbreviate the discussion by saying there are three “faiths” of grinding, and there are small-scale tests suitable for all three of the major faiths of ore hardness measurement.

For design purposes, you need an estimation or prediction of your SAG Mill’s tonnage; well, there are 3 ways to generate good rock “ore” hardness testing data for SAG and ball mill circuit grindability from half drill core. We can abbreviate the discussion by saying there are three “faiths” of grinding, and there are small-scale tests suitable for all three of the major faiths of ore hardness measurement.

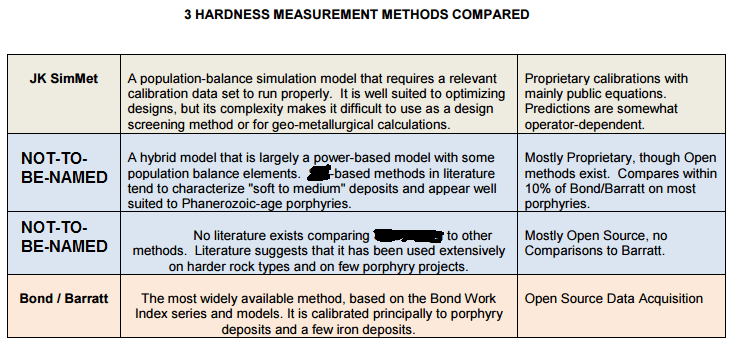

The first and cheapest method is also the most widely available method, based on the Bond work index series and models based on the work of people like Derek Barratt. This “Bond religion” typically costs less than $1200 per sample and you should be able to get steep discounts by obtaining a competitive bids. Labs like BaseMetLabs, ALS Global, SGS in Canada and Chile, Hazen, Corem, Dawson, Metso and TOMS can do this suite of testing. The Barratt form of this “faith” is calibrated principally to porphyry deposits, but I am also using it on iron deposits and think it works well there, too.

Avoid doing Bond work index tests at Australian labs as their geometry of work index rod mills is different from the geometry at the labs listed above. There are Australian Bond methods that are calibrated to these Australian rod mills, so if using an Australian Bond method you should avoid the labs in the Americas.

In September 2015, Mr. Morrell, from SMC published an article about the fact that ore hardness is geographically and commodity dependent; a very good read.

The Second Faith is the “NOT-TO-BE-NAMED” religion that is only available from NOT-TO-BE-NAMED laboratory at a cost of about $1500 per sample. A generic “NOT-TO-BE-NAMED” test is available from the NOT-TO-BE-NAMED labs in Chile and Peru that is usually cheaper than NOT-TO-BE-NAMED. After working extensively with NOT-TO-BE-NAMED, I feel it does a good job of characterizing “soft to medium” deposits and is well suited to Phanerozoic-age porphyries (head-to-head comparisons against Bond typically within 10%).

NOT-TO-BE-NAMED have a somewhat similar test named “NOT-TO-BE-NAMED” that corrects some of the problems in the original NOT-TO-BE-NAMED test, but (in my opinion) introduces new problems in the treatment of the ball mill. I suspect NOT-TO-BE-NAMED is calibrated to be more conservative than the NOT-TO-BE-NAMED model as the literature suggests NOT-TO-BE-NAMED‘s calibration is against harder rock types. I have never had the opportunity to use NOT-TO-BE-NAMED head-to-head with a “Bond” method, but would be very interested to do such a comparison.

https://www.911metallurgist.com/rod-ball-impact-crushing-abrasion-the-bond-work-index-family

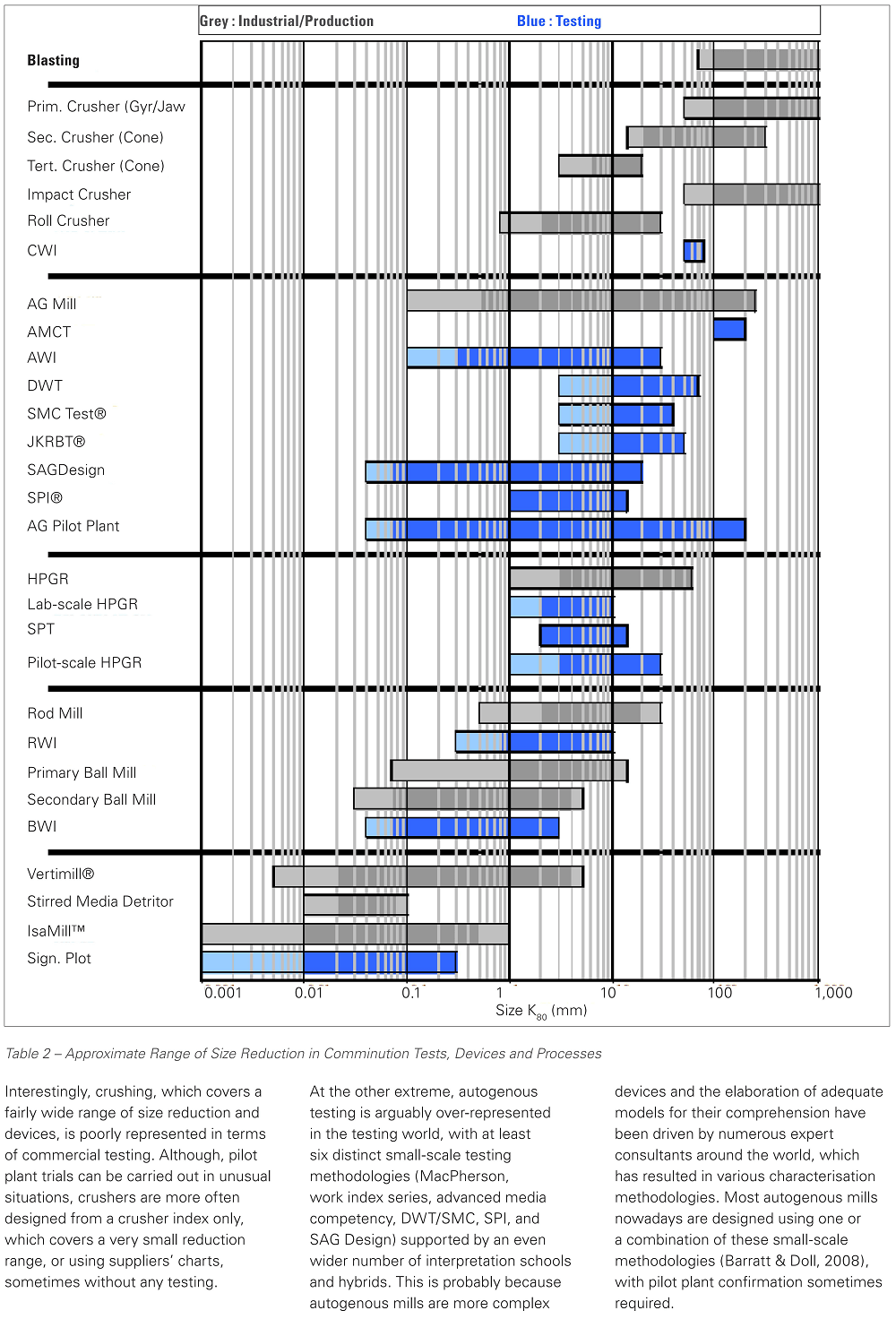

Last, in the ore hardness measurement world is the “Australian” Faith that takes the form of either the JK drop weight testing and population balance models by JK SimMet, or the SMC test and its power-based models by Morrell. The power-based SMC test is comparable to the other power-based methods ($1200-1500 per sample) but, arguably, has the poorest calibration to heterogeneous Phanerozoic-age porphyries. The JK drop weight test is the most expensive of the tests listed (up to $10,000 per sample) and most useful for population-balance calculations. The value in this family of tests is it permits some optimization of designs using the JK SimMet package (but JK SimMet is not a good tool for initial design – it is an optimizing software).

Alex Doll at SAGMilling.com has a website with extensive documentation that explores the gory detail of the benefits and problems with each of the methods is by SAG Mill Sizing Expert. Alex completed a Bachelor of Applied Science degree in Mining and Mineral Process Engineering at the University of British Columbia in Vancouver, Canada. He worked for eight years with Fluor Daniel on EPCM projects in Canada, the United States, Australia and Chile. He became an independent consultant in 2000 and spent four years as a process engineer in the Canadian oil-sands industry working on the massive Albian Sands and CNRL Horizon projects before spending a year as a project engineer on a copper-gold porphyry project. Since 2006, Alex has worked as a consultant in comminution circuit design, geo-metallurgical sampling and power-based circuit modelling. He started building the SAGMILLING.COM website in 2000 and has been steadily adding capability behind the scene with the goal of offering a Bond work index based software platform for doing SAG/ball mill circuit throughput estimates and mill sizing.

Read Alex’s Wiki