A number of methods to simulate the Bond work-index parameter are used and several of these methods have been reported in the literature. Smith and Lee used batch-type grindability tests to arrive at the work index. They made comparisons, at various grind sizes, with work index values using the standard Bond grindability tests.

Another method for simulating the Bond work index was reported by Berry and Bruce. Their method requires the use of a reference ore for which the work index is known. Using Bond’s comminution equation, “Third Theory of Comminution”,

where W = work required, kw-hr/ton

Wi= work index, kw-hr/ton

P = 80% passing size of product, microns

F = 80% passing size of feed, microns,

The rate of disappearance of material of size i is proportional to the amount of material of that size present in the ball mill expressed as

dci/dt = -kici

where ci = instantaneous mass fraction of i-th size, ki = comminution coefficient, t = time.

The laboratory procedure consists of the steps outlined below.

The laboratory grinding procedure for the reference ore and unknown ore should be identical regarding charge of ore ground, slurry solids, ball charge, ball-mill speed, and actual laboratory ball mill used. The laboratory procedure used at Cyprus Pima Mining Company consists of grinding 1,000 grams of minus 10 mesh ore at 60 percent solids using an 8-in. diameter by 8-in. long Booth laboratory ball mill. The grinding media consists of 8.1 kilograms of 1¼-inch diameter balls and the ball mill is operated at 75 rpm.

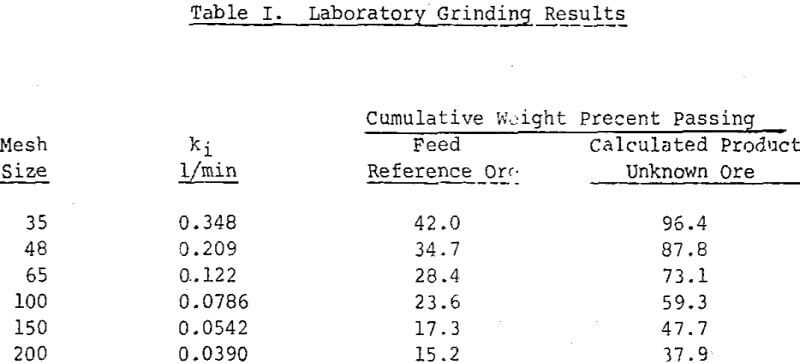

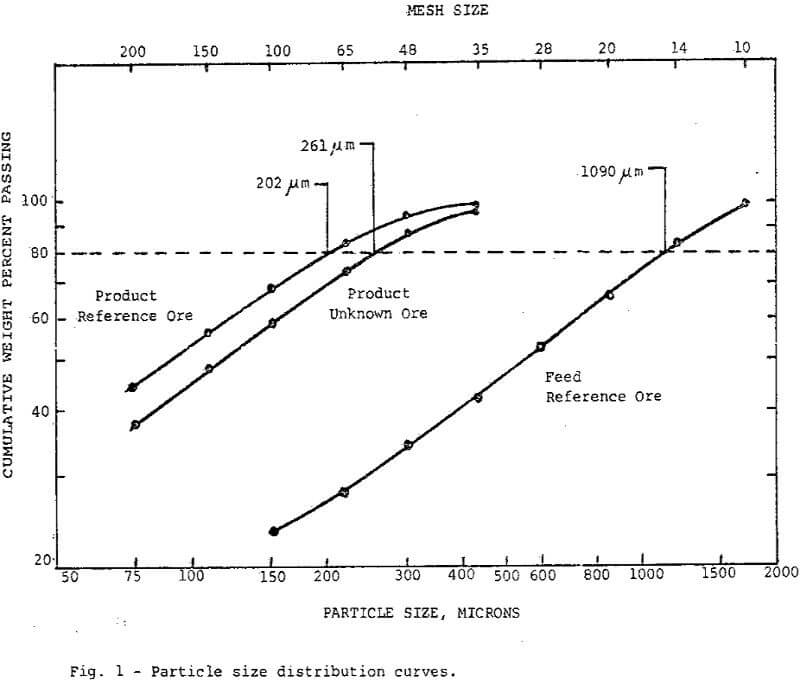

The comminution coefficients were computed using the least-squares criterion. Using the comminution coefficients, the product size distribution of the unknown ore can be computed using the feed size distribution of the reference ore and the grinding time established for the reference ore. Based on the example discussed above, the results would be

or Wiu = 16.2 kw-hr/ton.

An example of the typical differences experienced between grindability procedures is illustrated. These work index values were obtained using three different grindability techniques on samples of various ore types including samples from Cyprus Pima Mining Company’s copper operations south of Tucson, Arizona.

Operating results from Cyprus Pima Mining Company’s semi-autogenous grinding circuits can be used to illustrate how laboratory work index data can assist in the evaluation of plant performance. This is especially important when faced with variation in ore grinding characteristics/ which is typical in mining-milling operations.

With an operating baseline established for a specific grinding circuit or plant operation, it is possible to quantify improvements in plant performance when process modifications are made despite the fact that day-to-day or long-range changes in ore grindability occur. A process modification, namely a computer-based control system which has been described by Bailey and Carson, was installed at Cyprus Pima in the fall of 1974.