Lubrication of ordinary jaw crusher is usually attempted by one of several methods, such as grease, ring oiling or oil circulated by pump etc. Water jackets are frequently necessary to keep the larger bearing cool enough to run. These ordinary machines suffer from two grave defects. The first is small bearing area, insufficient to carry the severe loads imposed. The resulting high pressures in the bearing break through the lubrication film, and thus permit “metal to metal” contact between shaft and bearings. Good lubrication in such a bearing is impossible and water cooling is only a temporary relief, not a cure. Second practically all such bearings are exposed to showers of gritty, abrasive dust, that easily penetrate to the oily working surfaces, and thus form a rapid “grinding” compound. With the combination of extremely high bearing pressures and “abrasive” lubrication, is it any wonder that bearings wear out so quickly?

Now see how the entirely Kue-Ken design first eliminates the root of all bearings troubles, and then provides abundant clean lubrication. Each of the two movable jaws travels only half as much as the ordinary single jaw. The shaft eccentrics are at 1800 and in perfect balance. They are made with exceptionally long strokes. These long strokes are transmitted and reduced through oil bathed toggles to give the requisite powerful short strokes to each jaw. The simple method gives five times more leverage than other designs and consequently imposes only one-fifth the load and pressure on the shaft bearings. With the extremely large bearings used in Kue-Ken Crushers the bearing pressures per square inch are actually even less than one-fifth!

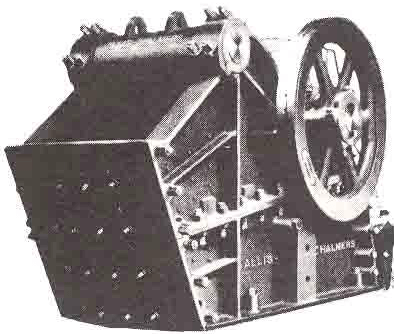

Now refer to the cutaway view below and see how every moving part is shielded in the sealed and dust free case, protected against grit and wear. Note the ample oil bath into which all toggles and pitmans splash. See how the oil pump cascades gallons of clean cool oil over the shaft and bearings. Real lubrication even in hottest climates, with light thin oil about/20 or/30 SAR. No wonder Kue-Ken bearings last so long!