When the pulp levels on all cells appears high (shallow froth bed thicknesses or depth). This causes unstable froth which constantly produces a low density “run-away” or wet, watery un-drained rougher concentrate rich in mechanically floated (entrained) “other materials” and containing most of the frother (added to flotation feed) itself. **

Operating at shallow froth bed causes much of the gangue rich “water” or slurry to poor over the lips of the flotation cell. This creates a rougher concentrate that is hard to clean for it was produced un-selectively, is of low grade and has a high concentration in chemical frother.

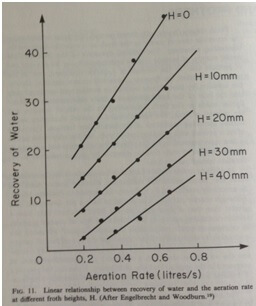

Here to the right, is a graph displaying the how froth depth affects water recovery to the concentrates. The more is recovered with shallow froth while concentrate grade drops as more water is recovered in it. Overall poor flotation selectivity will be seen shallow froth conditions occur in all roughing, scavenging and cleaning stages. Such shallow froth depth causes flooding, not floating of metals.

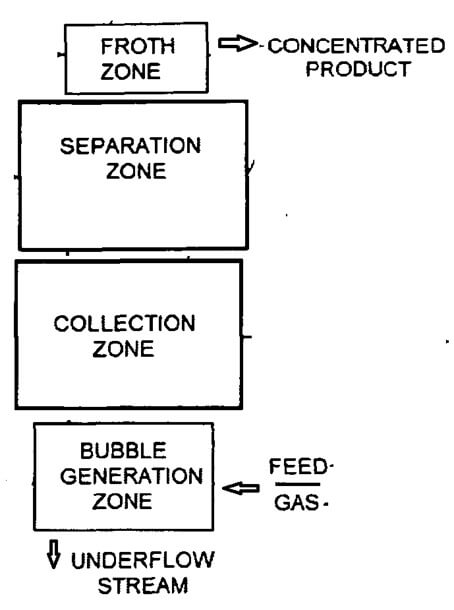

The froth bed level and the frother plays a critical role in the flotation of precious and base metals. Its main function is to stabilize the bubbles that transport the hydrophilic value minerals to the surface froth zone for exist of the cell over the lip. The correct froth bed leads to a better grade of recovered metal, improves recovery kinetics and gives operators better control of the flotation circuit.

What is unique about frother is its ability to strengthen the mineral loaded bubbles while allowing them to coalesce without rupturing, hence forming the froth zone.

Good frother and froth bed levels allow for sufficient froth liquid drainage so that entrained gangue minerals can be washed out and away.

Correct froth usage provides good froth mobility to transport the mineral particles to the cell’s lip and then into the launder to the next stage.

The froth zone must not collapse before the value metals can be recovered, yet must be sufficiently transient to allow its bubbles to break down and re-form in the next stage of flotation.

The perfect frother and frother addition will cause the bubbles to be stable enough to carry the weight of the wanted minerals, but not so stable that it survives beyond the launder and pump box.

Choosing and balancing froth flotation reagents must consider the plant configuration, the ore mineralogy, gangue associations, the froth persistence, froth liquid drainage, frother/collector interaction, pH, kinetics and all of their possible downstream effects.

Here is a great research paper of the topic https://www.sciencedirect.com/science/article/pii/S0892687512001537 showing how low grades and recoveries but high mass pull were obtained when operating with a shallow froth depth and low air recovery.